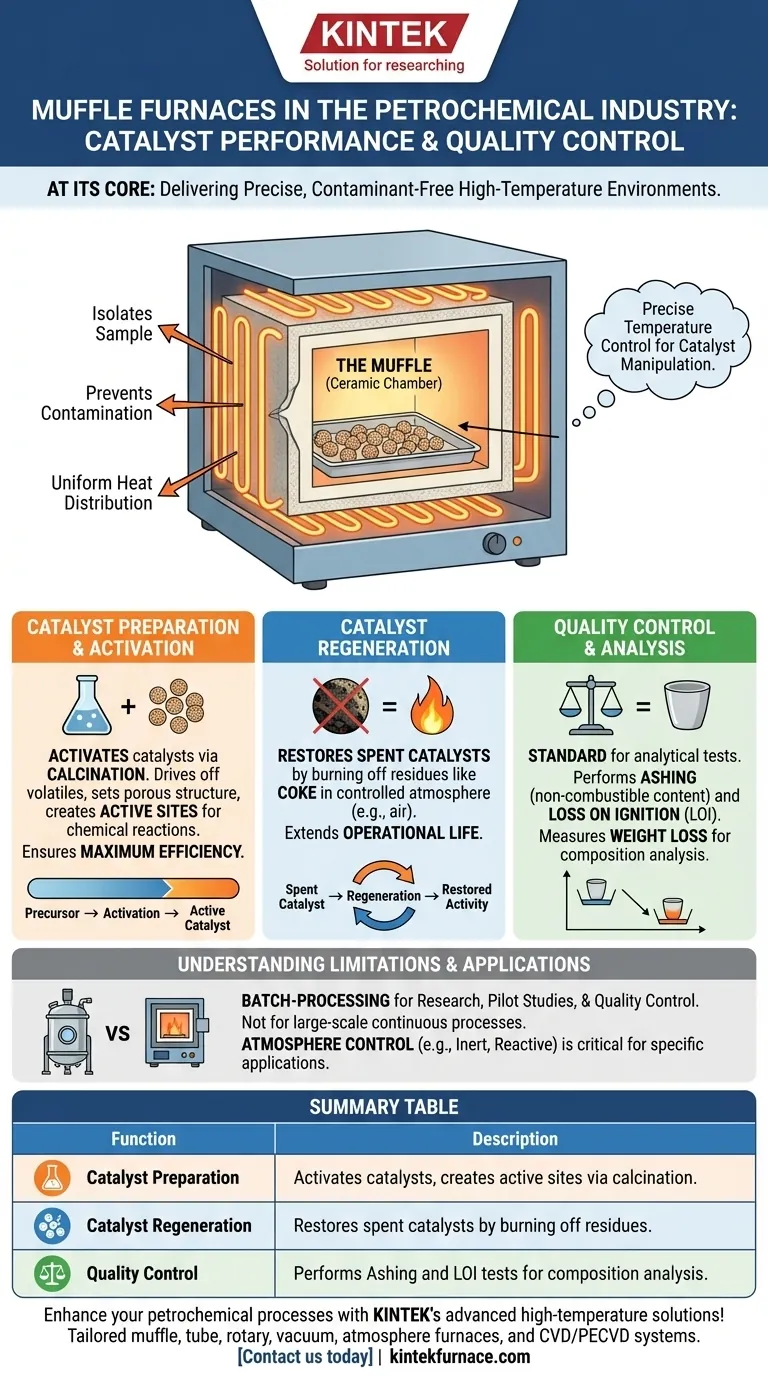

At its core, a muffle furnace serves a critical and highly specialized role in the petrochemical industry, primarily centered on the preparation, activation, and regeneration of catalysts. By providing an extremely controlled and contaminant-free high-temperature environment, these furnaces ensure that catalysts—the workhorses of petrochemical reactions—can perform with maximum efficiency and longevity.

The true value of a muffle furnace in petrochemical applications is not merely its ability to generate heat, but its capacity to deliver that heat with precision and purity. This control is essential for manipulating the delicate chemical and physical properties of catalysts, which directly impacts reaction yields and overall plant profitability.

The Principle: Controlled Thermal Processing

Before examining its specific applications, it's vital to understand what makes a muffle furnace unique. Its function is defined by its design.

What is the "Muffle"?

The key feature is the muffle, an insulated chamber made of refractory ceramic material that isolates the sample being heated from the heating elements and any combustion byproducts.

This design creates a clean environment, preventing contamination that could poison a sensitive catalyst or skew analytical results.

The Importance of Precision and Uniformity

Unlike a simple oven, a muffle furnace is engineered for precise temperature control and uniform heat distribution.

This allows for complex heating cycles with specific ramps and holds, which are necessary to induce desired chemical or physical changes in a material without damaging it.

Key Functions in the Petrochemical Industry

While muffle furnaces are versatile, their use in petrochemicals is concentrated on a few high-value tasks related to catalysts and quality control.

Catalyst Preparation and Activation

New catalysts often exist in a stable, precursor state. A muffle furnace is used to activate them through a carefully controlled heating process known as calcination.

This process drives off volatile components, sets the final porous structure, and creates the active catalytic sites necessary for chemical reactions. Without this precise thermal treatment, the catalyst would be ineffective.

Catalyst Regeneration

Over time, catalysts used in processes like fluid catalytic cracking (FCC) become fouled with coke and other residues, reducing their effectiveness.

A muffle furnace provides the ideal environment to regenerate these spent catalysts. By carefully heating them in a controlled atmosphere (often with air), the coke is burned off, restoring the catalyst's activity and extending its operational life.

Quality Control and Analysis

The petrochemical industry relies on rigorous testing. Muffle furnaces are standard laboratory instruments for several key analytical tests.

These include ashing, which determines the non-combustible content of crude oil, lubricants, or polymers, and Loss on Ignition (LOI), which measures weight loss upon heating and is used to analyze the composition of various materials.

Understanding the Limitations

While indispensable, it is crucial to recognize the specific role and limitations of a muffle furnace in an industrial context.

Not Suited for Large-Scale Continuous Processes

Muffle furnaces are fundamentally batch-processing instruments. They are ideal for laboratory research, pilot-scale studies, and quality control testing.

For the continuous, large-volume reactions that define most petrochemical plants, massive industrial reactors and regenerators are used instead. The principles, however, are often first developed and tested in a muffle furnace.

Atmosphere Control is a Key Consideration

While a standard muffle furnace heats in air, many catalyst processes require a specific inert (e.g., nitrogen) or reactive (e.g., hydrogen) atmosphere.

Furnaces with ports for gas exchange offer this capability, but this adds complexity and cost. Selecting a furnace with the appropriate atmosphere control is critical for the intended application.

Applying This to Your Goal

Your use of a muffle furnace will depend entirely on your specific objective within the petrochemical value chain.

- If your primary focus is research and development: The furnace is your essential tool for developing new catalyst formulations and defining their optimal activation protocols.

- If your primary focus is process optimization: Use the furnace to conduct regeneration studies that determine how to maximize the life and efficiency of the catalysts in your plant.

- If your primary focus is quality assurance: The muffle furnace is the industry-standard instrument for conducting critical compositional analyses like ashing on raw materials and final products.

Ultimately, the muffle furnace provides the precise thermal control necessary to manage the performance of the most valuable assets in petrochemical processing.

Summary Table:

| Function | Description |

|---|---|

| Catalyst Preparation | Activates catalysts via calcination to create active sites and porous structures. |

| Catalyst Regeneration | Restores spent catalysts by burning off residues like coke in controlled conditions. |

| Quality Control | Performs ashing and Loss on Ignition tests to analyze material composition and purity. |

Enhance your petrochemical processes with KINTEK's advanced high-temperature solutions! Leveraging exceptional R&D and in-house manufacturing, we provide muffle, tube, rotary, vacuum, atmosphere furnaces, and CVD/PECVD systems tailored for catalyst development and quality testing. Our deep customization ensures precise fit for your unique experimental needs. Contact us today to boost efficiency and yield in your lab or plant!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the core role of a muffle furnace in the synthesis of calcium oxide from eggshells? Achieve High-Purity CaO

- What is the primary function of a muffle furnace in iron-modified activated carbon prep? Optimize Adsorption Sites

- How does the use of a 100-mesh sieve contribute to the performance consistency of magnetic chitosan carbon?

- Why is re-calcination in a muffle furnace necessary for photocatalysts? Restore Efficiency via Thermal Oxidation

- What is the core function of a muffle furnace in CuO nanoparticle synthesis? Achieve Precision Calcination