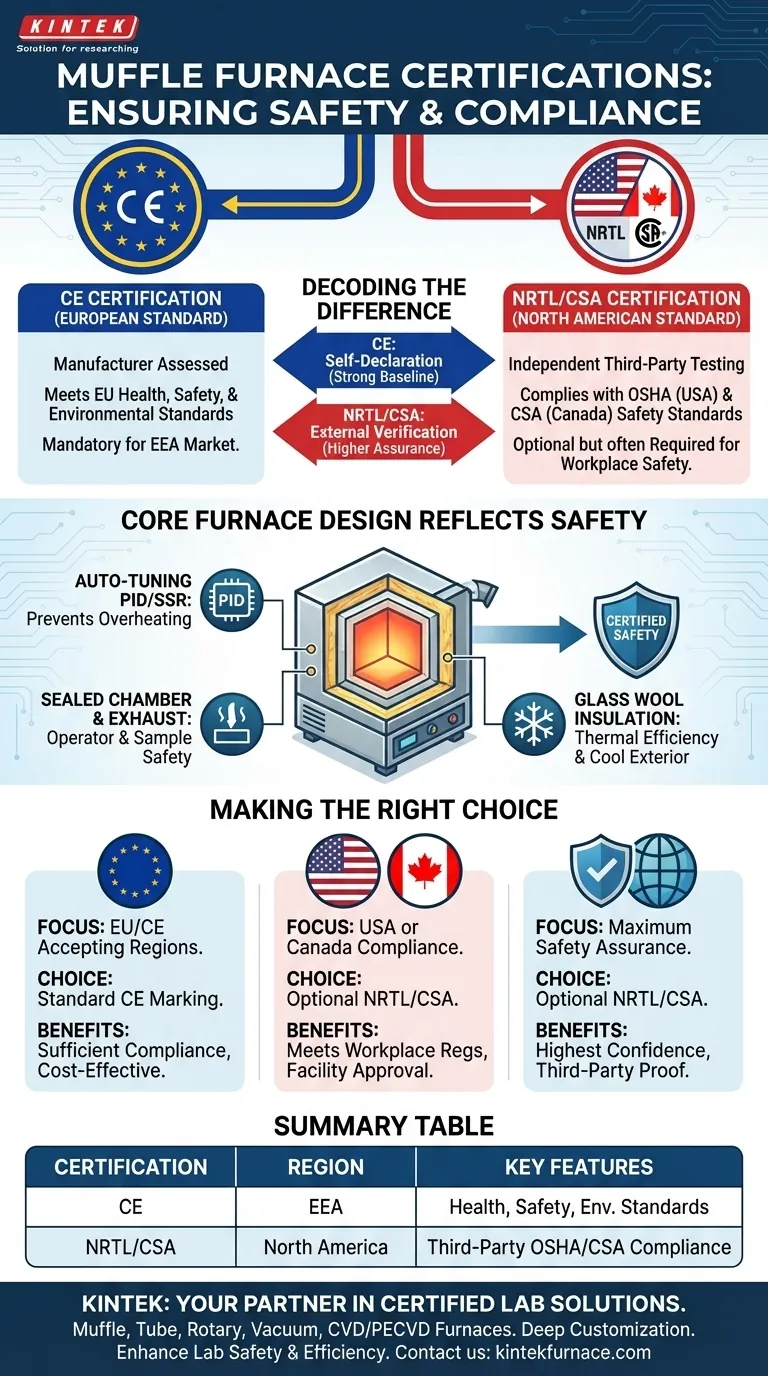

By default, this muffle furnace is CE certified. This certification confirms it meets the health, safety, and environmental protection standards for products sold within the European Economic Area. For users in North America or those requiring stricter validation, NRTL (Nationally Recognized Testing Laboratory) or CSA (Canadian Standards Association) certification is available upon request for an additional fee.

Certifications are a formal guarantee of a furnace's quality and safety. While CE marking is a strong baseline, understanding the distinction between standard and optional certifications is critical for ensuring compliance and operator safety in your specific work environment.

Decoding the Certifications

Certifications are not just labels; they represent adherence to specific, rigorous standards for electrical safety, operational integrity, and user protection.

CE Certification: The European Standard

The CE mark indicates that the manufacturer has assessed the product and it meets the EU's essential requirements for safety, health, and environmental protection. It is a mandatory conformity marking for products placed on the market in the European Economic Area.

NRTL and CSA: The North American Standard

NRTL is a designation from the U.S. Occupational Safety and Health Administration (OSHA) for organizations qualified to perform safety testing. CSA is a key standards organization in Canada.

These certifications involve independent, third-party testing to verify that a product complies with North American safety standards. They are often required for equipment used in workplaces to ensure regulatory compliance.

How Certifications Reflect Core Furnace Design

The certifications validate the inherent safety and performance features built directly into the furnace's design. A certified furnace has been scrutinized for its ability to operate safely at extreme temperatures.

Protection Against Overheating

To achieve certification, a furnace must demonstrate reliable temperature control. This is accomplished through features like an auto-tuning advanced PID controller and SSR-based heaters, which work together to prevent temperature overshoots and maintain stability.

Operator and Sample Safety

Safety is paramount. The sealed muffle chamber isolates the sample from direct heating elements, preventing contamination. An integrated exhaust system safely vents any gases produced during the heating process, protecting the operator and the lab environment.

Thermal Efficiency and Integrity

High-grade glass wool blanket insulation ensures maximum thermal efficiency. This not only provides uniform temperature for accurate results but also keeps the exterior of the furnace cool to the touch, preventing accidental burns and ensuring a safe laboratory environment.

Understanding the Trade-offs: Standard vs. Optional

Your choice of certification depends on a balance between regulatory requirements, risk management, and budget.

The Value of Standard CE Marking

For many labs, especially within the EU, CE certification is sufficient. It confirms the manufacturer has met its obligation to produce a safe and compliant product according to established European norms.

Why Invest in NRTL/CSA?

Opting for NRTL or CSA certification is a crucial investment for organizations in North America. These marks provide irrefutable, third-party proof that the equipment meets stringent local safety laws, which is often a non-negotiable requirement for insurance, facility inspections, and workplace safety compliance. The additional cost reflects this rigorous external validation process.

Making the Right Choice for Your Goal

Selecting the appropriate certification level is a critical decision that impacts compliance, safety, and your budget.

- If your primary focus is operating within the European Union or a region that accepts CE marking: The standard furnace certification is sufficient for your needs.

- If your primary focus is compliance in the United States or Canada: Investing in the optional NRTL or CSA certification is essential to meet workplace safety regulations and ensure facility approval.

- If your primary focus is maximum safety assurance regardless of location: The third-party verification provided by NRTL or CSA offers the highest level of confidence in the equipment's safety.

Ultimately, choosing the right certification is about aligning the equipment with your facility's specific regulatory and safety obligations.

Summary Table:

| Certification | Region Covered | Key Features |

|---|---|---|

| CE | European Economic Area | Health, safety, and environmental standards |

| NRTL/CSA | North America | Third-party testing for OSHA and CSA compliance |

Ensure your lab meets all safety and regulatory standards with KINTEK's certified high-temperature furnaces. Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with advanced solutions like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability precisely meets your unique experimental needs. Contact us today to discuss how our certified furnaces can enhance your lab's safety and efficiency!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure

- What is the role of a muffle furnace in the study of biochar regeneration and reuse? Unlock Sustainable Water Treatment