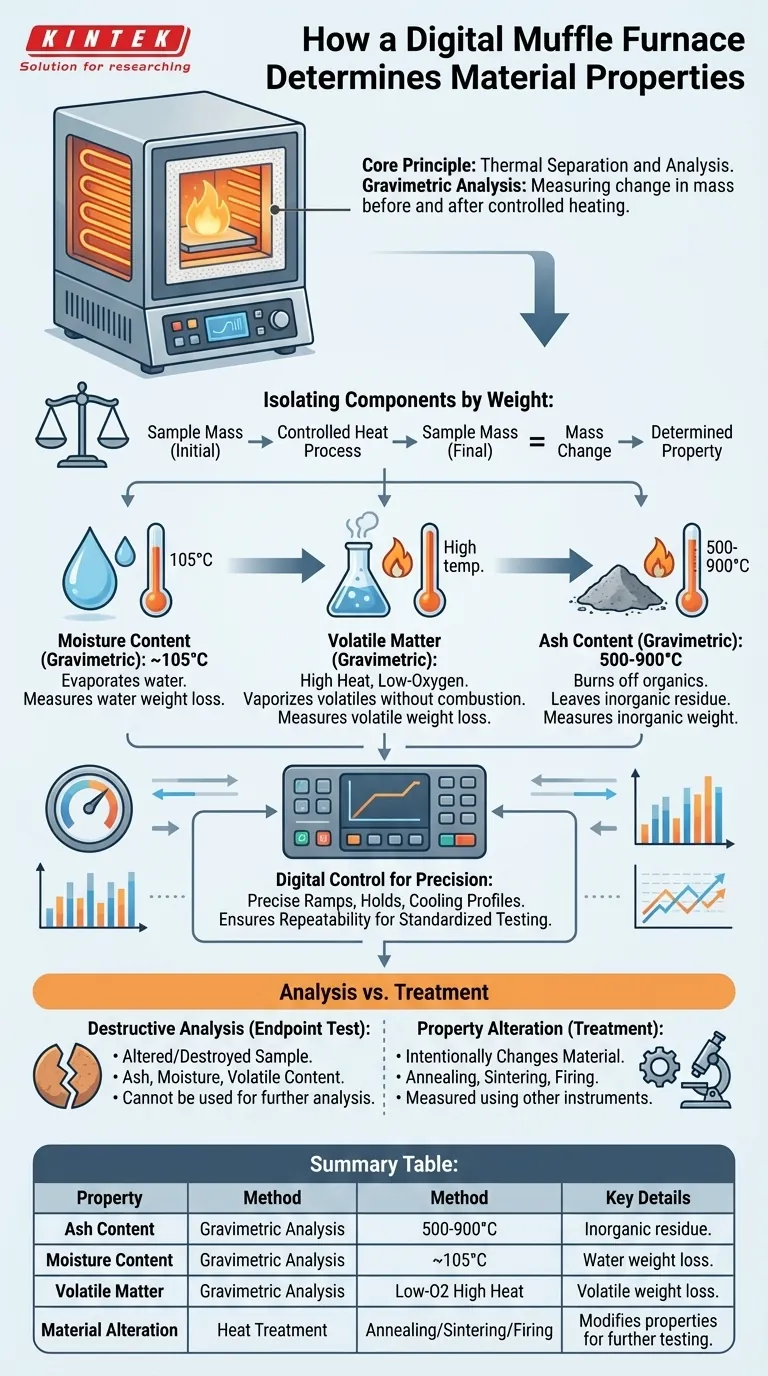

At its core, a digital muffle furnace determines material properties by using precise, high-temperature heat to induce a physical or chemical change in a sample. This controlled thermal process allows for the quantitative analysis of components like moisture, volatile matter, and ash by measuring the change in the sample's mass before and after heating.

The true function of a muffle furnace is not merely to heat things up. It is a tool for controlled decomposition and transformation, allowing you to isolate, remove, or alter specific components of a material for accurate measurement and analysis.

The Core Principle: Thermal Separation and Analysis

A muffle furnace is essentially a high-temperature oven where the heating elements are separated from the main chamber by a "muffle," or retractable lining. This design ensures the sample is heated uniformly by radiation and convection without being contaminated by combustion byproducts from the heating elements.

Isolating Components by Weight

The most common analytical method involves gravimetric analysis—measuring weight. A sample is weighed, heated to a specific temperature for a set duration, cooled in a moisture-free environment (a desiccator), and then weighed again.

The difference in mass reveals the quantity of the component that was burned off or evaporated. This simple principle is the foundation for determining several key properties.

The Role of Digital Control

A digital controller is critical for this work. It allows for precise temperature ramps, holds (soaks), and cooling profiles. This repeatability is essential for standardized testing (like ASTM or ISO methods) and ensuring that results are comparable across different labs and times.

Key Properties Determined Through Heating

By carefully selecting the temperature and atmosphere, a muffle furnace can isolate and quantify different fractions of a material.

Determining Ash Content

This is one of the most frequent uses. The furnace heats a sample to a high temperature (typically 500-900°C) to completely burn off all organic and volatile matter.

The non-combustible inorganic residue that remains is the ash content. This is a critical quality parameter in industries like food science, coal analysis, and environmental testing.

Measuring Moisture Content

To measure moisture, the furnace is set to a much lower temperature, usually just above the boiling point of water (around 105°C).

This drives off the free water without thermally decomposing the sample itself. The weight loss corresponds directly to the moisture content.

Quantifying Volatile Matter

Volatile matter includes substances (other than water) that vaporize at high temperatures. To measure this, a sample is heated in a covered crucible to limit the presence of air.

This high-heat, low-oxygen environment forces volatile compounds to vaporize without combusting. The subsequent weight loss, after accounting for moisture, represents the volatile content.

Understanding the Trade-offs and Applications

While powerful, it's important to understand the context in which a muffle furnace is used. Its role extends beyond simple analysis into material modification.

Most Analysis is Destructive

For determining properties like ash or volatile content, the original sample is fundamentally altered or destroyed. This means it is an endpoint test, and the sample cannot be used for further analysis.

Analysis vs. Property Alteration

There are two primary ways a furnace is used:

- For Analysis: Heating to measure a component that is removed (ash, moisture).

- For Treatment: Heating to intentionally change a material's properties (annealing, sintering), which are then measured using other instruments.

For example, a furnace is used for annealing to make a metal more ductile. Its improved ductility is then measured with a tensile tester, not the furnace itself. The furnace is the tool for treatment, not the final measurement of the new property.

Other Heat Treatment Applications

The furnace is also central to processes like sintering (fusing powders into a solid), brazing (joining metals), and firing ceramics. In these cases, the furnace creates or modifies a material for a specific high-performance application.

Making the Right Choice for Your Goal

The way you use a muffle furnace depends entirely on your objective.

- If your primary focus is compositional analysis (e.g., food, coal, biomass): Your goal is to use gravimetric analysis to determine ash, moisture, and volatile content according to standardized methods.

- If your primary focus is metallurgy or materials science: You will use the furnace for heat treatment processes like annealing, hardening, or sintering to modify a material's microstructure and mechanical properties for further testing.

- If your primary focus is ceramic engineering: You will use the furnace for firing, co-firing, and shaping technical ceramics to achieve desired density, strength, and thermal characteristics.

A muffle furnace is a foundational instrument that leverages heat to reveal, create, or refine the fundamental properties of a material.

Summary Table:

| Property Determined | Method | Key Details |

|---|---|---|

| Ash Content | Gravimetric analysis | Heated to 500-900°C to burn off organics, leaving inorganic residue. |

| Moisture Content | Gravimetric analysis | Heated to ~105°C to evaporate water, measuring weight loss. |

| Volatile Matter | Gravimetric analysis | Heated in low-oxygen environment to vaporize compounds without combustion. |

| Material Alteration | Heat treatment | Used for processes like annealing, sintering, and firing to modify properties for further testing. |

Enhance your laboratory's capabilities with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems tailored to your unique needs. Our deep customization ensures precise performance for compositional analysis, metallurgy, and ceramic engineering. Contact us today to discuss how our furnaces can improve your material property determinations and drive innovation in your research.

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production

- What metals cannot be heated by induction? Understanding Material Suitability for Efficient Heating

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control