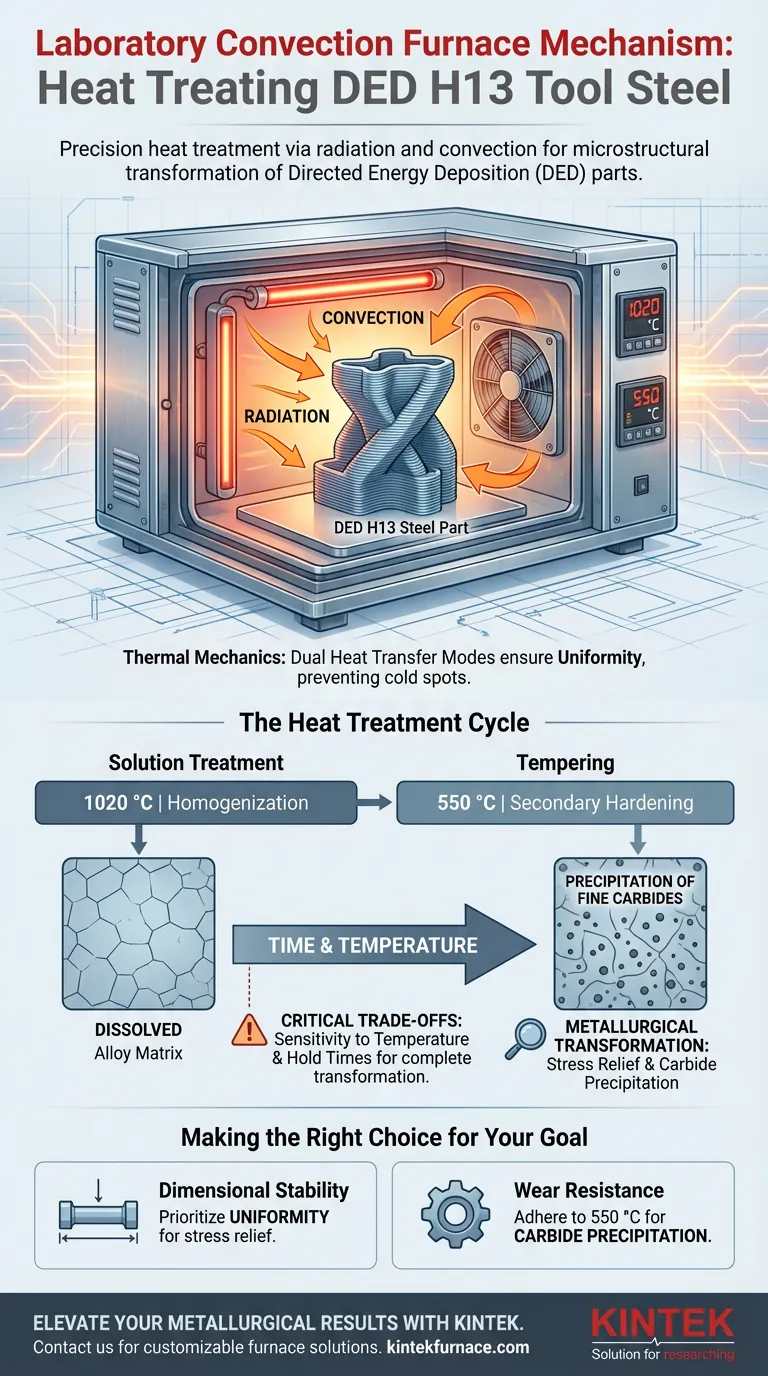

The primary mechanism of a laboratory convection furnace operates through a combination of radiation and convection to establish a strictly controlled high-temperature environment. For H13 tool steel produced via Directed Energy Deposition (DED), this furnace executes a precise thermal cycle—specifically solution treatment at 1020 °C and tempering at 550 °C—to ensure uniform heating throughout the component.

While the physical mechanism involves thermal transfer, the functional purpose is metallurgical transformation. The furnace facilitates the precipitation of fine carbides from a supersaturated martensitic matrix, a critical step that relieves residual stresses and activates secondary hardening.

Thermal Mechanics of the Furnace

Dual Heat Transfer Modes

The laboratory furnace utilizes two distinct physics principles to heat the H13 steel. Radiation transfers heat directly from the heating elements to the sample surfaces, which is effective at high temperatures.

Simultaneously, convection circulates heated air or gas around the chamber. This ensures that heat penetrates the complex geometries often found in DED parts, preventing cold spots that purely radiative heating might miss.

Ensuring Thermal Uniformity

Uniformity is the critical output of this mechanism. DED parts often have anisotropic (direction-dependent) properties due to the layer-by-layer building process.

The convection furnace mitigates this by enveloping the sample in a consistent thermal field. This ensures that the microstructural changes described below occur evenly across the entire volume of the steel.

Microstructural Transformation of DED H13 Steel

The Role of Solution Treatment

The first phase of the mechanism involves holding the steel at 1020 °C. At this temperature, the furnace environment allows for solution treatment.

This step prepares the microstructure by homogenizing the alloy elements within the steel matrix, setting the stage for the subsequent hardening phases.

The Role of Tempering

Following the solution treatment, the furnace is utilized for tempering at 550 °C. This specific temperature point is vital for H13 tool steel.

It is during this phase that the "secondary hardening" effect is triggered. The furnace maintains this temperature to allow the material to settle into a harder, more durable state suitable for industrial use.

Precipitation of Fine Carbides

The most complex mechanism facilitated by the furnace is the transformation of the steel's matrix. The heat treatment forces the precipitation of fine carbides from the supersaturated martensitic matrix.

In the context of DED, the material begins with a supersaturated structure due to rapid cooling during printing. The furnace unlocks this structure, releasing the carbides to reinforce the steel.

Stress Relief

DED processes inherently introduce high residual stresses due to rapid thermal cycling during manufacturing.

The convection furnace acts as a stress-relief chamber. By maintaining controlled heat, it allows the internal lattice structures of the steel to relax, reducing the risk of cracking or distortion in the final part.

Understanding the Trade-offs

Sensitivity to Temperature Fluctuations

The mechanism relies entirely on precision. If the furnace deviates from the target temperatures of 1020 °C or 550 °C, the microstructural benefits are compromised.

Inaccurate temperatures can lead to incomplete carbide precipitation or failure to relieve residual stress, rendering the DED part structurally unsound.

The Time-Temperature Dependency

This is not an instantaneous process. The furnace mechanism requires specific hold times to allow the heat to fully penetrate the part via convection.

Rushing this process negates the benefits of uniformity, particularly in thicker or denser DED components where heat transfer to the core takes longer.

Making the Right Choice for Your Goal

To maximize the utility of a laboratory convection furnace for H13 DED parts, focus on your specific metallurgical objectives:

- If your primary focus is dimensional stability: Prioritize the uniformity of the convection mechanism to ensure complete relief of residual stresses, preventing future warping.

- If your primary focus is wear resistance: Ensure strict adherence to the 550 °C tempering setpoint to maximize the precipitation of fine carbides and achieve full secondary hardening.

Precise thermal control is the bridge between a raw printed part and an industrial-grade tool.

Summary Table:

| Heat Treatment Stage | Temperature Setpoint | Key Mechanism | Metallurgical Outcome |

|---|---|---|---|

| Solution Treatment | 1020 °C | Homogenization | Dissolves alloying elements into the matrix |

| Tempering | 550 °C | Secondary Hardening | Precipitation of fine carbides from martensite |

| Thermal Transfer | Variable | Radiation & Convection | Ensures uniform heating and prevents cold spots |

| Stress Relief | Continuous | Lattice Relaxation | Mitigation of residual stresses from DED process |

Elevate Your Metallurgical Results with KINTEK

Precision is non-negotiable when treating H13 tool steel produced by Directed Energy Deposition. KINTEK provides the advanced thermal technology required to achieve perfect microstructural transformation and stress relief.

Backed by expert R&D and world-class manufacturing, we offer a comprehensive range of lab solutions including:

- Muffle & Tube Furnaces for ultra-precise atmosphere control.

- Vacuum & CVD Systems for high-purity thermal cycles.

- Rotary & Custom High-Temp Furnaces tailored to your specific DED post-processing needs.

Ready to transform your 3D-printed parts into industrial-grade tools? Contact us today to find your customizable furnace solution.

Visual Guide

References

- A Comparative Study of Directed Energy Deposition‐Arc and Casting: Enhancing Mechanical and Thermal Properties of Hot‐Work Tool Steels. DOI: 10.1002/srin.202500424

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

People Also Ask

- How does temperature control work in modern muffle furnaces? Achieve Unmatched Precision and Efficiency

- What are the main applications of box type electric furnaces? Unlock Precision in Material Processing

- What are the primary functions of laboratory resistance furnaces in lead refining? Achieve 700°C Thermal Precision

- How does a high-temperature chamber sintering furnace contribute to fluorite tailing-based geopolymer precursors?

- What material properties can be achieved using a box furnace? Unlock Enhanced Hardness, Strength, and More

- What are the different types of muffle furnaces and their features? Choose the Right One for Your Lab

- What is the function of a laboratory box-type high-temperature furnace? Master AlCoCrFeNi2.1 Heat Treatment Evolution

- What features might advanced muffle furnace models include? Enhance Precision, Safety, and Efficiency