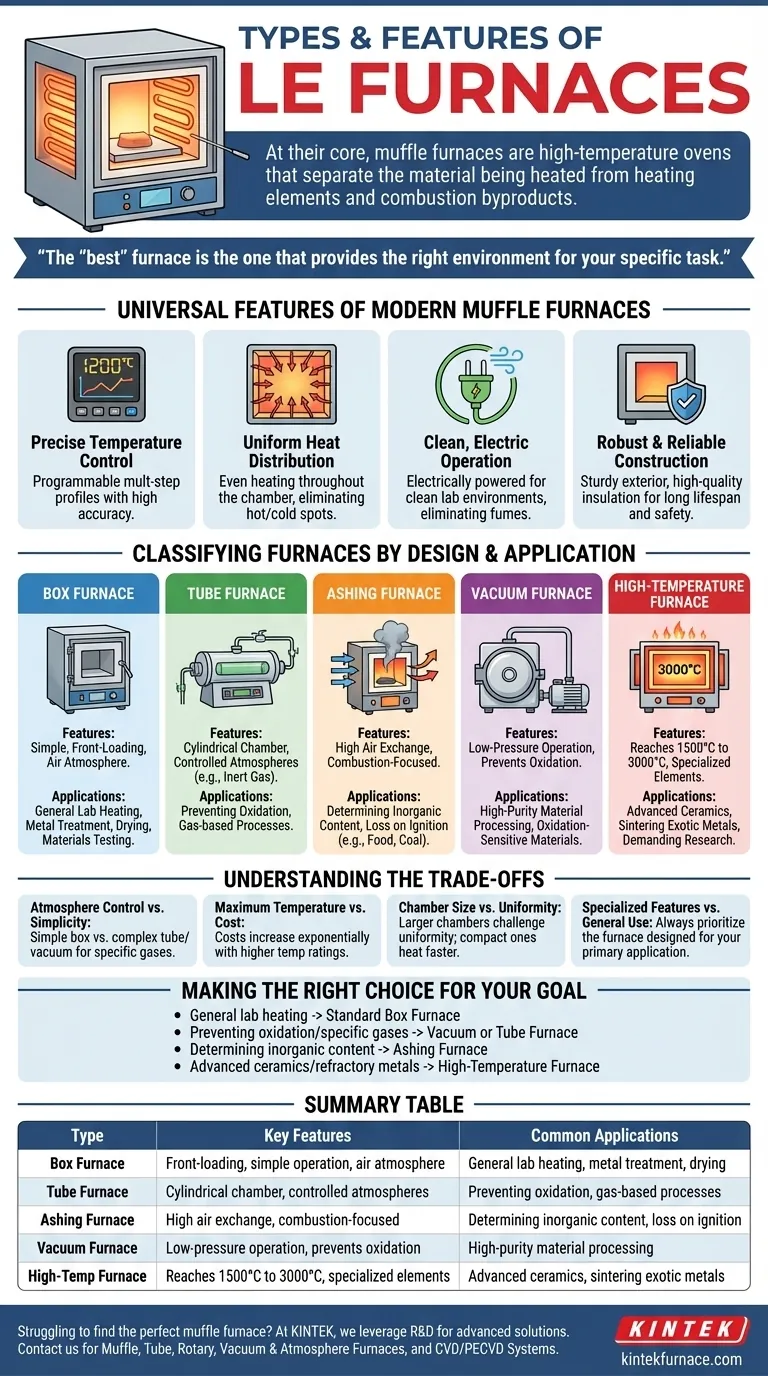

At their core, muffle furnaces are high-temperature ovens that separate the material being heated from the heating elements and any combustion byproducts. They are primarily categorized by their physical construction (such as box or tube) and their specialized application (like ashing or operating under a vacuum), with features tailored to specific scientific and industrial processes.

The most critical factor in selecting a muffle furnace is not its maximum temperature, but how its design—specifically its chamber shape and atmosphere control—aligns with your material processing objective. The "best" furnace is the one that provides the right environment for your specific task.

The Universal Features of Muffle Furnaces

Before examining the different types, it's important to understand the features common to nearly all modern muffle furnaces. These form the baseline of expected performance.

Precise Temperature Control

A key function is the ability to program and maintain specific temperatures with high accuracy. Advanced digital controllers allow for multi-step programs, enabling precise control over heating rates, soak times, and cooling rates.

Uniform Heat Distribution

Quality furnaces are designed to provide even heating throughout the entire chamber. This is often achieved by embedding heating elements within the ceramic "muffle" or strategically placing them to eliminate hot and cold spots, ensuring consistent results.

Clean, Electric Operation

Most laboratory muffle furnaces are electrically powered. This design eliminates the fumes, noise, and potential contamination associated with fuel-fired furnaces, making them ideal for clean lab environments.

Robust and Reliable Construction

These devices are built for long-term use at extreme temperatures. They typically feature sturdy steel exteriors and high-quality insulation materials to ensure operator safety, energy efficiency, and a long operational lifespan.

Classifying Furnaces by Design and Application

The primary differences between furnace types emerge from their intended purpose. Each design is optimized for a specific set of tasks.

The General-Purpose "Box" Furnace

This is the most common type found in general laboratory settings. It features a simple, front-loading box-shaped chamber suitable for a wide array of applications like heat-treating metals, drying, and materials testing where a normal air atmosphere is acceptable.

The "Tube" Furnace for Controlled Atmospheres

A tube furnace uses a cylindrical chamber, typically made of ceramic or quartz. Its design makes it easy to seal the ends, allowing users to purge the air and introduce specific gases (like nitrogen or argon) to create a controlled, inert, or reactive atmosphere.

The "Ashing" Furnace for Combustion

Specifically designed for determining the inorganic content of a sample, or "loss on ignition." These furnaces feature a very high rate of air exchange, continuously introducing fresh air to accelerate the combustion of organic materials like food, plastics, or coal.

The "Vacuum" Furnace for Preventing Oxidation

For materials that are highly sensitive to oxygen at high temperatures, a vacuum furnace is essential. These units can be pumped down to a low pressure, removing nearly all the air to prevent oxidation and ensure material purity.

High-Temperature Furnaces for Advanced Materials

While standard furnaces operate up to 1200°C, high-temperature models can reach 1500°C, 1800°C, or even 3000°C. They are required for processing advanced ceramics, sintering exotic metals, and other demanding industrial or research applications.

Understanding the Trade-offs

Choosing a furnace involves balancing capability, complexity, and cost. There is no single solution that is best for every task.

Atmosphere Control vs. Simplicity

A simple box furnace is easy to operate and less expensive. However, if your process requires an inert gas or a vacuum, the added complexity and cost of a tube or vacuum furnace are unavoidable.

Maximum Temperature vs. Cost

The cost of a furnace increases exponentially with its maximum temperature rating. Furnaces capable of operating above 1500°C require specialized heating elements (like molybdenum disilicide or tungsten) and advanced insulation, making them significantly more expensive.

Chamber Size vs. Uniformity

Larger furnace chambers offer more capacity but can present challenges in maintaining perfect temperature uniformity. Smaller, compact furnaces often heat up faster and provide excellent uniformity for smaller samples.

Specialized Features vs. General Use

An ashing furnace is exceptional at combustion but is not ideal for general-purpose heat treating. Always prioritize the furnace designed for your primary application rather than a general model that may perform it poorly.

Making the Right Choice for Your Goal

Select your furnace by matching its core design to your primary objective.

- If your primary focus is general lab heating or basic metal treatment: A standard box muffle furnace offers the best balance of performance and cost.

- If your primary focus is preventing oxidation or using specific process gases: You must use a vacuum furnace or a tube furnace designed for atmosphere control.

- If your primary focus is determining the inorganic content of samples: An ashing furnace with high airflow is the only appropriate tool.

- If your primary focus is working with advanced ceramics or refractory metals: A high-temperature furnace with the required temperature rating is non-negotiable.

Ultimately, understanding your process requirements is the key to selecting the right tool for the job.

Summary Table:

| Type | Key Features | Common Applications |

|---|---|---|

| Box Furnace | Front-loading, simple operation, air atmosphere | General lab heating, metal treatment, drying |

| Tube Furnace | Cylindrical chamber, controlled atmospheres (e.g., inert gases) | Preventing oxidation, gas-based processes |

| Ashing Furnace | High air exchange, combustion-focused | Determining inorganic content, loss on ignition |

| Vacuum Furnace | Low-pressure operation, prevents oxidation | High-purity material processing |

| High-Temperature Furnace | Reaches 1500°C to 3000°C, specialized elements | Advanced ceramics, sintering exotic metals |

Struggling to find the perfect muffle furnace for your lab? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your unique experimental requirements. Our product line includes Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities. Whether you need precise temperature control, uniform heating, or specialized atmospheres, we can help you achieve superior results. Contact us today to discuss how our furnaces can enhance your lab's efficiency and performance!

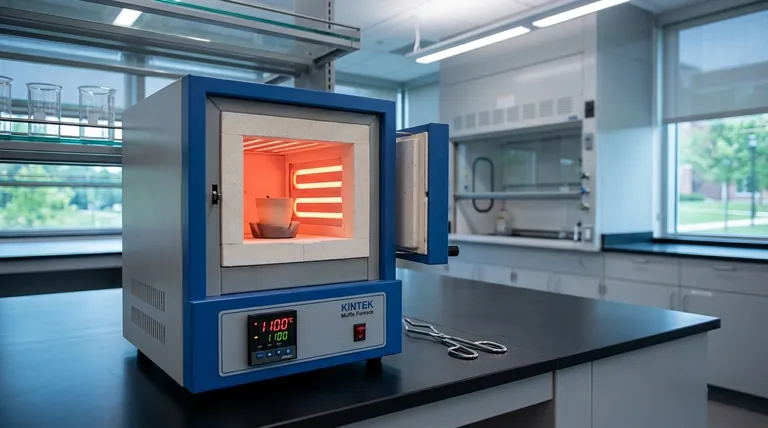

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What is the core function of a muffle furnace in CuO nanoparticle synthesis? Achieve Precision Calcination

- What is the function of a muffle furnace in SiCf/Al-Mg pretreatment? Optimize Fiber Bonding with Thermal De-sizing

- What is the primary function of a muffle furnace in iron-modified activated carbon prep? Optimize Adsorption Sites

- What is the function of a muffle furnace during 500°C pre-calcination? Master CeZrPAl Support Synthesis

- What is the primary function of a high-temperature box resistance furnace? Optimize Superalloy Homogenization