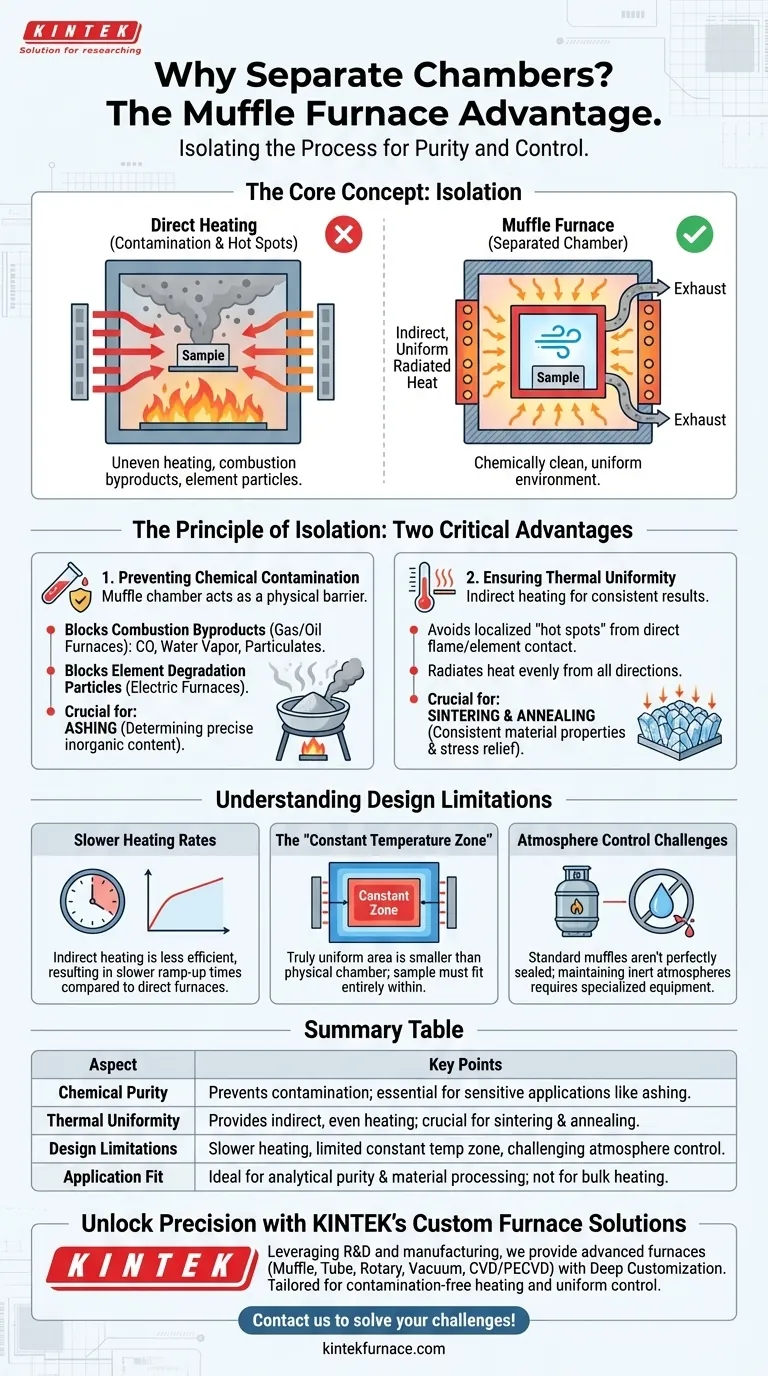

At its core, the separation of chambers in a muffle furnace is the defining feature that guarantees process purity. This design isolates the material being processed from direct contact with heating elements or the byproducts of combustion. This separation creates a chemically clean, uniform heating environment essential for sensitive thermal applications.

The fundamental purpose of a muffle furnace isn't just to get hot, but to do so in a controlled and non-contaminating way. The separated chamber, or "muffle," is the mechanism that transforms a simple oven into a precise instrument for scientific and industrial processes.

The Principle of Isolation: Purity and Control

The term "muffle" refers to the inner chamber that contains the sample. Its role is to act as a barrier, which provides two distinct and critical advantages: chemical purity and thermal uniformity.

Preventing Chemical Contamination

In fuel-fired furnaces, the combustion of gas or oil produces a host of byproducts, including carbon monoxide, water vapor, and various particulates. If these came into contact with the sample, they could cause unwanted chemical reactions, altering the material's composition.

The muffle chamber creates a physical barrier, ensuring that only clean, heated air or a controlled atmosphere surrounds the sample. This is non-negotiable for applications like ashing, where the goal is to determine the precise inorganic content of a sample by burning away all organic matter.

Ensuring Thermal Uniformity

Direct exposure to heating elements or flames creates intense, localized "hot spots." This uneven heating leads to inconsistent results, as different parts of the sample experience different temperatures.

The muffle chamber solves this by absorbing heat from the external elements and then radiating it evenly onto the sample from all directions. This indirect heating is crucial for processes like sintering or annealing, where uniform temperature is required for consistent crystal growth and stress relief in the material.

Protecting Samples from Heating Elements

Even in electric furnaces, which have no combustion, the heating elements themselves can degrade over time at extreme temperatures. They may shed microscopic particles that can contaminate a sensitive sample. The muffle provides a durable, inert barrier between the elements and the workpiece.

Understanding the Design Limitations

While indispensable for many tasks, the muffle furnace design comes with inherent trade-offs that are important to understand.

Slower Heating Rates

Indirect heating is inherently less efficient than direct heating. The heat must first transfer to the muffle chamber, which then radiates it to the sample. This results in slower temperature ramp-up times compared to a direct-fired furnace, which can be a limitation in high-throughput environments.

The "Constant Temperature Zone"

A furnace chamber is never perfectly uniform in temperature. The area near the door is often cooler, and areas near the elements are hotter. The truly uniform area, or constant temperature zone, is always smaller than the physical dimensions of the chamber. For best results, the sample must be sized and placed to fit entirely within this zone.

Atmosphere Control Requires Effort

While many muffle furnaces include a port to introduce specific gases (like nitrogen or argon), standard models are not perfectly sealed. Maintaining a truly inert or reducing atmosphere is challenging and often requires a more specialized, sealed retort furnace. The port is more effective for venting fumes or monitoring temperature with a secondary probe.

Making the Right Choice for Your Application

Understanding the function of the muffle chamber allows you to match the tool to the task.

- If your primary focus is analytical purity (e.g., ashing for content analysis): The muffle's isolation is non-negotiable to prevent contamination from skewing your results.

- If your primary focus is material processing (e.g., sintering or annealing): The uniform, indirect heating provided by the muffle is critical for achieving consistent material properties and structure.

- If your primary focus is simply bulk heating without sensitivity to contamination: A simpler, direct-fired oven may provide faster and more energy-efficient results.

By appreciating that the separated chamber is a tool for control, you can ensure your thermal processing is both precise and repeatable.

Summary Table:

| Aspect | Key Points |

|---|---|

| Chemical Purity | Prevents contamination from combustion byproducts or heating elements, essential for ashing and sensitive applications. |

| Thermal Uniformity | Provides indirect, even heating to avoid hot spots, crucial for sintering and annealing. |

| Design Limitations | Slower heating rates, limited constant temperature zone, and challenges in atmosphere control. |

| Application Fit | Ideal for analytical purity and material processing; less suitable for bulk heating without sensitivity. |

Unlock Precision in Your Lab with KINTEK's Custom Furnace Solutions

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Whether you need contamination-free heating for ashing or uniform thermal control for sintering, we can tailor a furnace to enhance your process purity and efficiency.

Contact us today to discuss how our expertise can solve your specific thermal processing challenges and boost your lab's performance!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- Why is re-calcination in a muffle furnace necessary for photocatalysts? Restore Efficiency via Thermal Oxidation

- What is the core function of a muffle furnace in CuO nanoparticle synthesis? Achieve Precision Calcination

- What is the function of a muffle furnace in SiCf/Al-Mg pretreatment? Optimize Fiber Bonding with Thermal De-sizing

- What is the function of a muffle furnace during 500°C pre-calcination? Master CeZrPAl Support Synthesis

- What is the primary function of a muffle furnace in iron-modified activated carbon prep? Optimize Adsorption Sites