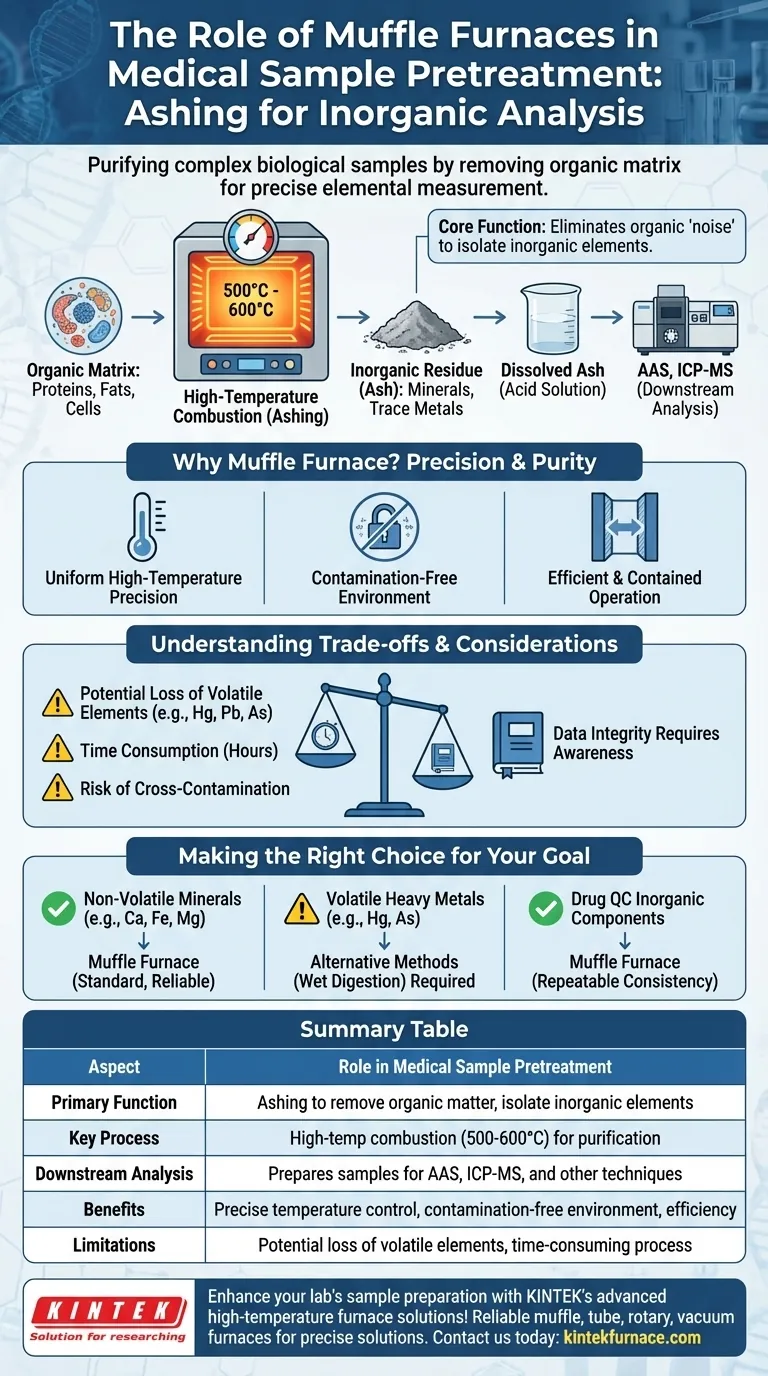

In medical and pharmaceutical research, the primary role of a muffle furnace is to prepare biological samples for inorganic elemental analysis through a high-temperature process called ashing. This procedure uses extreme heat to completely burn away all organic matter—like proteins, fats, and cellular structures—leaving behind only the non-volatile inorganic components, such as minerals and trace metals, for subsequent measurement.

The core function of a muffle furnace in this context is not to analyze the sample itself, but to act as a crucial purification step. It eliminates the complex organic "noise" from a medical sample, thereby isolating the inorganic elements for accurate and sensitive downstream analysis.

The Core Function: Ashing for Elemental Analysis

To understand the furnace's role, you must first understand the purpose of ashing. It is a method of sample digestion that prepares a complex biological specimen for a very specific type of chemical analysis.

What is Ashing?

Ashing is a process of controlled, high-temperature combustion. The sample is placed in an inert crucible and heated in the furnace to temperatures typically between 500°C and 600°C.

At these temperatures, all organic compounds are oxidized and converted into gaseous substances (like carbon dioxide and water vapor), which are then vented. What remains is a small amount of "ash"—the inorganic residue.

Removing the Organic Matrix

The vast majority of a biological sample (e.g., blood, tissue, or a pharmaceutical compound) is made of a complex organic matrix. This matrix interferes with analytical techniques designed to measure trace levels of minerals or metals.

The muffle furnace systematically removes this interference, ensuring that the final analysis is only measuring the target inorganic elements.

Preparing for Downstream Analysis

The resulting ash is the actual sample used for further testing. The residue is typically dissolved in an acid solution and then introduced to highly sensitive analytical instruments.

Common downstream techniques include atomic absorption spectroscopy (AAS) or inductively coupled plasma (ICP) mass spectrometry. These instruments are incapable of processing whole organic samples and rely on the clean, inorganic sample prepared by the furnace.

Why a Muffle Furnace is Essential for This Task

While other heating methods exist, the specific design of a muffle furnace makes it uniquely suited for the demands of precise medical sample preparation.

High-Temperature Precision

Muffle furnaces provide extremely uniform and stable temperatures. This consistency is critical to ensure the complete combustion of all organic material without causing certain volatile inorganic elements to be lost.

Contamination-Free Environment

The term "muffle" refers to the furnace's design, where the sample is physically separated from the heating elements. The sample sits inside a sealed chamber, preventing any contamination from the heating coils, which is paramount when measuring elements at parts-per-million or parts-per-billion concentrations.

Efficient and Contained Operation

Modern muffle furnaces are built with thick insulation and tightly sealed doors. This design retains heat effectively, reducing power consumption and ensuring the high temperatures are safely contained within the chamber. The robust stainless steel housing ensures durability in a demanding lab environment.

Understanding the Trade-offs and Considerations

While indispensable, using a muffle furnace for dry ashing is not without its limitations. An expert must be aware of these trade-offs to ensure data integrity.

Potential Loss of Volatile Elements

The primary drawback of high-temperature ashing is the potential loss of volatile elements. Certain metals and minerals, such as mercury, lead, and arsenic, can vaporize at the temperatures used. If these are the elements of interest, an alternative, lower-temperature "wet ashing" method using acids may be required.

Time Consumption

Ashing is not a rapid process. Depending on the sample size and type, the procedure can take several hours to complete. This must be factored into the laboratory's workflow and timeline.

Risk of Cross-Contamination

Strict protocols are necessary to prevent cross-contamination between samples. Crucibles must be scrupulously cleaned between uses, and the furnace chamber must be kept free of any residual ash to ensure the purity of each analysis.

Making the Right Choice for Your Goal

Your analytical objective dictates how you should approach this preparatory step.

- If your primary focus is quantifying non-volatile minerals (e.g., calcium, iron, magnesium): Muffle furnace ashing is the industry-standard, most reliable method for preparing your sample.

- If your primary focus is analyzing for volatile heavy metals (e.g., mercury, arsenic): You must use alternative methods like wet digestion or specialized equipment, as a standard muffle furnace will likely lead to inaccurate, underestimated results.

- If your primary focus is quality control of a drug's inorganic components: A muffle furnace provides the repeatable consistency needed to verify that product batches meet their required specifications.

By mastering this crucial preparatory step, you ensure the integrity and accuracy of your final analytical results.

Summary Table:

| Aspect | Role in Medical Sample Pretreatment |

|---|---|

| Primary Function | Ashing to remove organic matter and isolate inorganic elements |

| Key Process | High-temperature combustion (500-600°C) for purification |

| Downstream Analysis | Prepares samples for AAS, ICP-MS, and other techniques |

| Benefits | Precise temperature control, contamination-free environment, efficiency |

| Limitations | Potential loss of volatile elements, time-consuming process |

Enhance your lab's sample preparation with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable muffle, tube, rotary, vacuum, atmosphere furnaces, and CVD/PECVD systems. Our strong deep customization capability ensures precise solutions for your unique experimental needs, such as accurate ashing for medical samples. Contact us today to discuss how we can support your research and improve analytical accuracy!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the role of a muffle furnace in the study of biochar regeneration and reuse? Unlock Sustainable Water Treatment

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control