At their core, box-type electric furnaces are precision instruments used in ceramics to transform raw or powdered materials into solid, durable, and functional components through highly controlled heat treatment. Their primary applications are firing, sintering, and melting, which are fundamental processes for creating everything from traditional pottery to advanced electronic parts.

A box furnace is not merely an oven; it is a critical tool that enables the precise manipulation of a material's internal structure. Its value lies in its ability to execute programmed temperature cycles, which are essential for achieving specific densities, strengths, and electrical properties in the finished ceramic product.

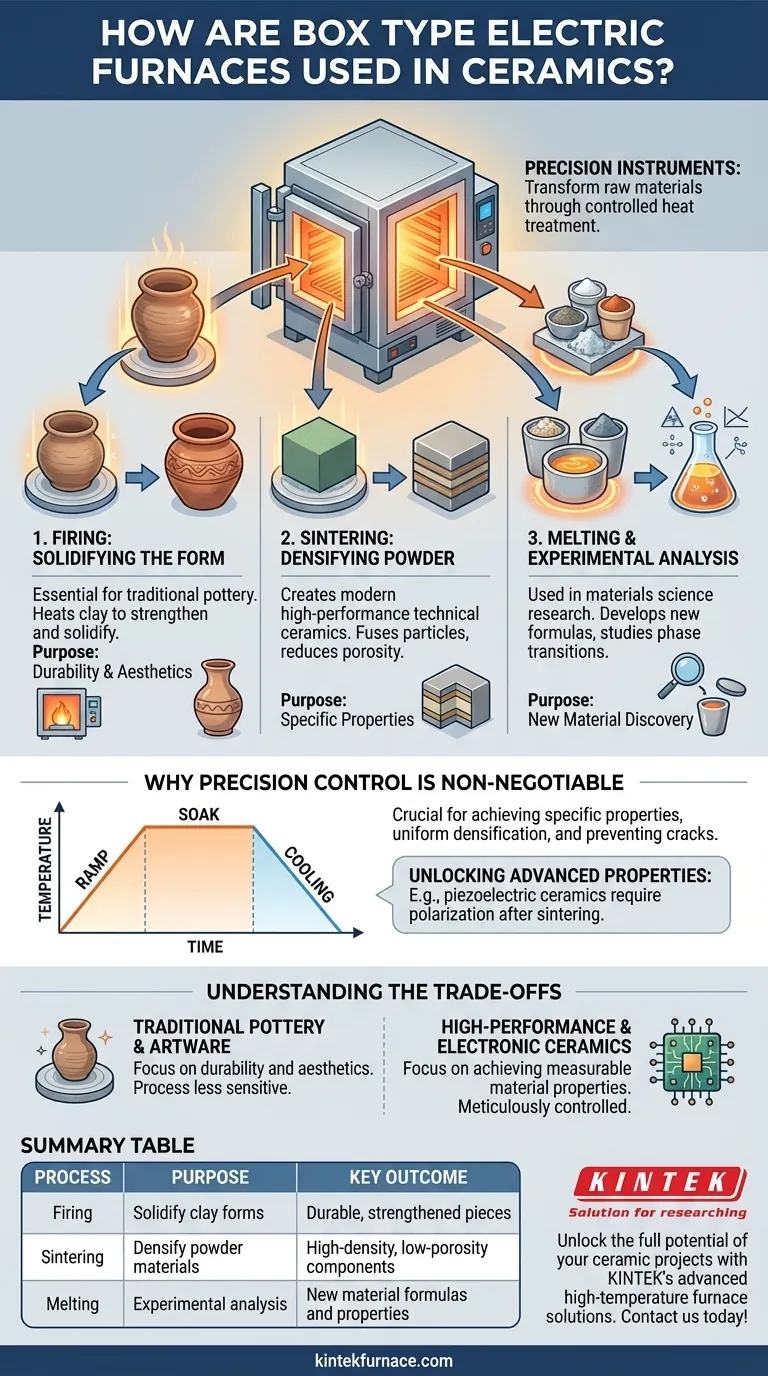

The Fundamental Processes Enabled by Furnaces

A box-type electric furnace's role in ceramics can be broken down into three main thermal processes. Each one serves a distinct purpose in material transformation.

Firing: Solidifying the Form

Firing is the most traditional and widely understood use of a furnace in ceramics, essential in pottery-making.

The process involves heating formed clay to high temperatures, which causes chemical and physical reactions that solidify and permanently strengthen the material, turning it into a durable ceramic piece.

Sintering: Densifying Powder into a Solid

Sintering is a critical process for creating modern, high-performance technical ceramics.

It involves heating a compacted powder material to a temperature below its melting point. This causes the individual particles to fuse, removing organic binders and reducing porosity to create a dense, solid object.

A key example is in the production of Multilayer Ceramic Capacitors (MLCCs), where sintering is used to densify the layered ceramic and electrode materials.

Melting & Experimental Analysis

For materials science and research, box furnaces are used to melt ceramic compositions.

This allows researchers to create new glass or ceramic formulas, study phase transitions, and perform various heat treatment experiments to develop novel materials with unique properties.

Why Precision Control is Non-Negotiable

Simply reaching a high temperature is not enough. The true value of a modern electric furnace lies in its ability to precisely manage the entire heating and cooling cycle.

The Role of Programmed Temperature Control

Advanced ceramics require specific thermal profiles. This includes the rate of temperature increase (ramp), the duration at peak temperature (soak), and the rate of cooling.

This programmed control is crucial for preventing cracks, achieving uniform densification, and developing the desired crystalline structure within the material.

Unlocking Advanced Properties

Certain advanced materials only gain their unique characteristics after a specific heat treatment.

For example, piezoelectric ceramics must undergo a polarization treatment after sintering. This involves heating the material in the furnace within a strong electric field to align its internal domains, which is what gives the material its ability to generate a voltage under pressure.

Understanding the Trade-offs and Context

While versatile, the specific application dictates how the furnace is used. The goals for firing a simple clay pot are vastly different from those for sintering a complex electronic component.

For Traditional Pottery & Artware

In this context, the primary goals of firing are durability and aesthetics. The furnace cycle is designed to mature the clay body and properly set the glazes. The process is often less sensitive to minute variations compared to technical ceramics.

For High-Performance & Electronic Ceramics

Here, the goal is achieving specific, measurable material properties. The sintering process is meticulously controlled to manage shrinkage, ensure maximum density, and produce the required electrical or mechanical characteristics for a functional component.

Making the Right Choice for Your Goal

Your objective determines which furnace process is most critical.

- If your primary focus is durable pottery or artware: Firing is your essential process to transform fragile clay into a strong, permanent object.

- If your primary focus is advanced technical components: Sintering is the key to densifying ceramic powders and engineering specific high-performance properties.

- If your primary focus is materials science research: The furnace enables melting and experimental heat treatments to discover and refine new ceramic compositions.

Ultimately, the box furnace is the tool that unlocks the vast potential hidden within ceramic materials.

Summary Table:

| Process | Purpose | Key Outcome |

|---|---|---|

| Firing | Solidify clay forms | Durable, strengthened ceramic pieces |

| Sintering | Densify powder materials | High-density, low-porosity components |

| Melting | Experimental analysis | New material formulas and properties |

Unlock the full potential of your ceramic projects with KINTEK's advanced high-temperature furnace solutions. Whether you're in pottery, electronics, or materials research, our Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems offer precision control and deep customization to meet your unique needs. Contact us today to enhance your lab's efficiency and achieve superior results!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety