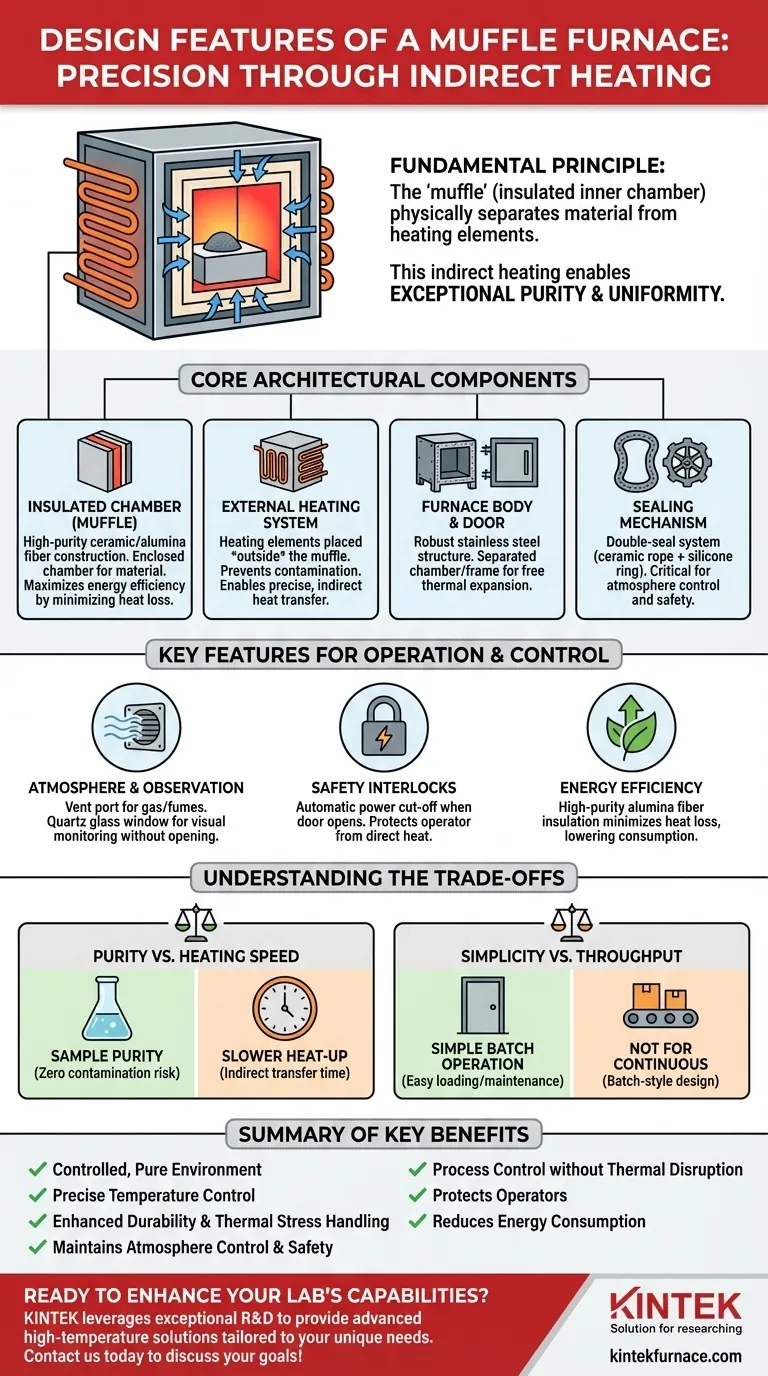

The fundamental design feature of a muffle furnace is its use of an insulated inner chamber, known as the muffle, which is heated externally. This creates a highly controlled environment by physically separating the material being heated from the heating elements. This principle of indirect heating is what enables the furnace to provide exceptional temperature uniformity and protect the sample from contamination.

A muffle furnace is engineered for precision and purity. Its key design features—an isolated chamber, external heating, and robust sealing—all work together to create an exceptionally stable and clean high-temperature environment.

The Core Architectural Components

The effectiveness of a muffle furnace stems from how its primary components are designed and integrated.

The Insulated Chamber (The Muffle)

The core of the furnace is the muffle itself, an enclosed chamber that holds the material. It is typically constructed from high-purity, heat-resistant materials like ceramic or alumina fiber.

This chamber is surrounded by high-grade insulation to maximize energy efficiency by minimizing heat loss to the outside environment.

The External Heating System

Unlike other furnaces, the heating elements are placed outside the muffle. Heat is transferred radiantly and convectively through the muffle walls to the sample inside.

This indirect heating is the single most important design choice, preventing any potential contamination of the sample by the heating elements. Modern systems often use solid-state relays for quieter, more precise power delivery.

The Furnace Body and Door

The entire assembly is housed in a robust structure, often made of stainless steel for durability and corrosion resistance.

In many designs, the furnace chamber and outer frame are built separately. The chamber may rest on rollers, allowing it to expand and contract freely during temperature cycles without stressing the overall structure.

The Sealing Mechanism

A tight seal is critical for atmosphere control and safety. High-performance furnaces often feature a double-seal system on the door, using an inner ceramic fiber rope and an outer silicone rubber ring.

The door locking mechanism, such as a multi-point handwheel, ensures even pressure. The hinges are often designed to move with the furnace body as it expands, maintaining a perfect seal at all temperatures.

Key Features for Operation and Control

Beyond the core structure, specific features are included to enhance usability, safety, and process control.

Atmosphere and Observation

A vent port is commonly included on top of the furnace. This allows for the controlled flow of gases or the venting of fumes produced during a heating process.

Many models also incorporate a small quartz glass observation window, allowing the user to visually monitor the material without opening the door and disrupting the thermal environment.

Safety Interlocks

Safety is paramount in high-temperature equipment. A critical feature is a door interlock that automatically cuts power to the heating elements when the door is opened, protecting the operator from direct heat exposure.

Energy Efficiency

The quality of the insulation is a key design factor. Using high-purity alumina fiber insulation and ensuring a stable, well-sealed structure prevents heat from dissipating, which lowers energy consumption.

Understanding the Trade-offs

The design of a muffle furnace prioritizes certain outcomes, which introduces inherent trade-offs compared to other furnace types.

Purity vs. Heating Speed

The primary benefit of indirect heating is sample purity. There is zero risk of contaminants flaking off the heating elements and falling onto your material.

The trade-off is potentially slower heat-up rates. Since heat must transfer through the muffle wall, the response time can be slightly longer than in a furnace where elements are directly exposed to the chamber.

Simplicity vs. Throughput

The typical muffle furnace is a box-shaped, batch-style instrument. Loading and unloading occur through a single door, which makes operation and maintenance very simple and straightforward.

This design is not suited for continuous processing. If high throughput is the goal, a different type of furnace, like a conveyor or rotary kiln, would be more appropriate.

Making the Right Choice for Your Goal

The importance of each design feature depends entirely on your specific application.

- If your primary focus is material purity and analysis: The most critical feature is the indirect heating provided by the separate muffle, which prevents sample contamination.

- If your primary focus is controlled atmosphere processing: Look for designs with advanced multi-layer door seals, movable hinges, and dedicated gas inlet/outlet ports.

- If your primary focus is durability and long service life: Prioritize robust construction, such as stainless steel housing and a decoupled frame design that manages thermal expansion.

Ultimately, the thoughtful and deliberate design of the muffle furnace makes it an indispensable tool for applications demanding precision, cleanliness, and reliability.

Summary Table:

| Feature | Description | Key Benefit |

|---|---|---|

| Insulated Chamber (Muffle) | Made of heat-resistant materials like ceramic or alumina fiber, surrounded by insulation | Provides a controlled, pure environment and energy efficiency |

| External Heating System | Heating elements placed outside the muffle for indirect heat transfer | Prevents sample contamination and ensures precise temperature control |

| Furnace Body and Door | Constructed from durable stainless steel with expansion-tolerant designs | Enhances durability and handles thermal stress during cycles |

| Sealing Mechanism | Uses double-seal systems with ceramic fiber and silicone rubber for tight closure | Maintains atmosphere control and safety at high temperatures |

| Atmosphere and Observation | Includes vent ports and quartz glass windows for gas flow and visual monitoring | Allows process control without disrupting thermal stability |

| Safety Interlocks | Door interlocks that cut power when opened | Protects operators from heat exposure and improves safety |

| Energy Efficiency | High-quality insulation like alumina fiber minimizes heat loss | Reduces energy consumption and operating costs |

Ready to enhance your laboratory's capabilities with a custom muffle furnace? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature solutions tailored to your unique needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities. Whether you're focused on material purity, controlled atmospheres, or durability, we can design a furnace that precisely meets your experimental requirements. Contact us today to discuss how we can support your research and development goals!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What key step does a Muffle Furnace perform in the determination of mineral content in Tenebrio molitor larvae?

- What is the function of a muffle furnace in SiCf/Al-Mg pretreatment? Optimize Fiber Bonding with Thermal De-sizing

- What is the core role of a muffle furnace in the synthesis of calcium oxide from eggshells? Achieve High-Purity CaO

- What is the function of a muffle furnace during 500°C pre-calcination? Master CeZrPAl Support Synthesis

- Why is re-calcination in a muffle furnace necessary for photocatalysts? Restore Efficiency via Thermal Oxidation