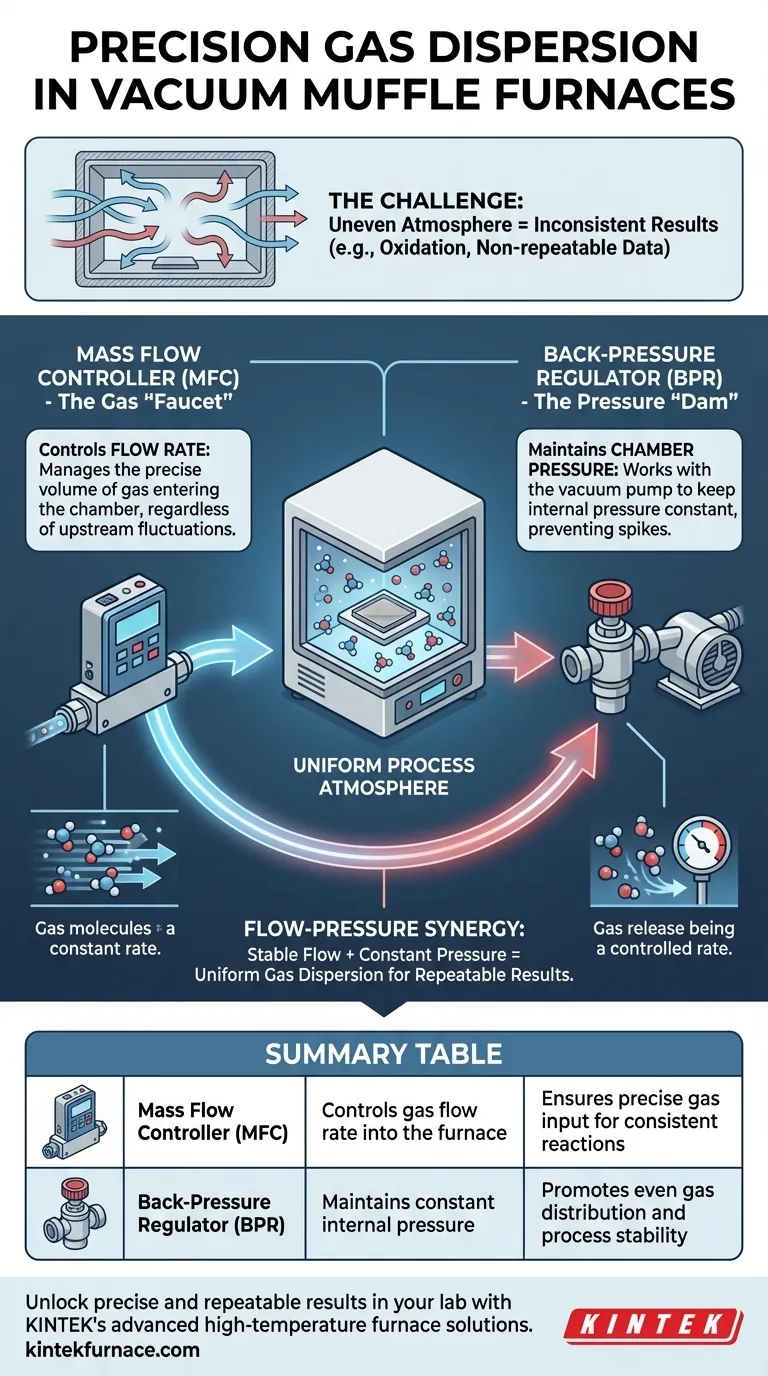

To ensure precise gas dispersion, vacuum muffle furnaces rely on a coordinated system of two primary components: a Mass Flow Controller (MFC) and a Back-Pressure Regulator (BPR). The MFC precisely controls the volume of gas entering the furnace chamber, while the BPR works with the vacuum pump to maintain a constant internal pressure, guaranteeing that the incoming gas is distributed evenly throughout the space.

The core principle is a two-part control strategy. One component governs the rate of gas flow into the chamber, while the second governs the pressure within the chamber. This synergy is what transforms a simple heated box into a precise and repeatable atmospheric processing tool.

The Challenge: Creating a Uniform Process Atmosphere

Achieving a perfectly controlled atmosphere inside a high-temperature furnace is a significant engineering challenge. Without precise control, gas can stratify, create pockets of inconsistent atmosphere, or flow unevenly over the sample.

This lack of uniformity can ruin experiments or production runs, leading to issues like incomplete chemical reactions, material oxidation, or non-repeatable test results for applications like metallurgical analysis or polymer testing.

The Two-Part System for Gas Control

To solve this, modern vacuum muffle furnaces use a sophisticated system where two components work in tandem. Thinking of it as a system, rather than as individual parts, is the key to understanding its effectiveness.

The Mass Flow Controller (MFC): The Gas "Faucet"

The Mass Flow Controller (MFC) is the component responsible for managing the amount of gas introduced into the furnace.

Think of it as a highly intelligent, automated faucet. You program it for a specific gas and a specific flow rate (e.g., in milliliters per minute), and it delivers that exact amount, regardless of upstream pressure fluctuations.

As noted in technical specifications, high-end MFCs can be pre-programmed to accurately manage dozens of different gases, providing the flexibility needed for diverse research and testing applications.

The Back-Pressure Regulator (BPR): The Pressure "Dam"

While the MFC controls the gas input, the Back-Pressure Regulator (BPR) controls the chamber's internal environment. It is placed on the exhaust line, just before the vacuum pump.

Its job is to maintain a constant, stable pressure inside the furnace. It works like a dam, releasing just enough gas to the vacuum pump to keep the internal pressure at a precise, predetermined level.

This prevents pressure drops or spikes that would cause the gas from the MFC to disperse erratically. The result is a calm, steady-state environment where the process gas can be distributed uniformly.

How They Work Together: The Flow-Pressure Synergy

Neither component can ensure precision on its own. It is the combination of a stable flow rate and stable pressure that guarantees uniform gas dispersion.

The MFC provides a constant, known quantity of gas. The BPR ensures the "room" that gas is filling has a constant, known pressure.

This synergy eliminates atmospheric variables, ensuring that every part of your sample is exposed to the exact same gas conditions. This is the foundation of reliable and repeatable high-temperature processing.

Understanding the System's Limitations

While highly effective, this system's precision depends on proper maintenance and an understanding of its potential failure points.

Calibration is Non-Negotiable

An MFC is only as good as its last calibration. If the controller's sensor drifts, it will report an incorrect flow rate, invalidating your process parameters. Regular calibration against a known standard is essential for mission-critical work.

The Vacuum Pump is a Critical Partner

The BPR can only regulate the pressure that the vacuum pump creates. A weak, failing, or improperly sized pump will be unable to achieve the necessary vacuum level, rendering the BPR ineffective and compromising the entire atmospheric system.

Gas Purity and Compatibility

The system precisely controls the flow of gas, but it cannot control its quality. Using impure or contaminated gas will introduce unwanted variables into your process. Furthermore, you must ensure the selected process gas is not corrosive to the furnace chamber, sensors, or gaskets at your target temperature.

Making the Right Choice for Your Goal

Understanding this system allows you to ensure your equipment is performing optimally for your specific application.

- If your primary focus is material purity and annealing: Your key concern is the MFC's ability to deliver a steady, uninterrupted flow of inert gas like argon or nitrogen to prevent any oxidation.

- If your primary focus is process repeatability for quality control: You must validate the performance of both the MFC and BPR, as their synergy is what ensures every run has identical atmospheric conditions.

- If your primary focus is analytical testing like ashing: The MFC's precision is paramount, as it ensures the reactive gas (like oxygen) is supplied at a controlled rate for complete and uniform combustion.

Mastering the relationship between gas flow and chamber pressure is the key to unlocking consistent, reliable, and accurate results from your vacuum muffle furnace.

Summary Table:

| Component | Function | Key Benefit |

|---|---|---|

| Mass Flow Controller (MFC) | Controls gas flow rate into the furnace | Ensures precise gas input for consistent reactions |

| Back-Pressure Regulator (BPR) | Maintains constant internal pressure | Promotes even gas distribution and process stability |

Unlock precise and repeatable results in your lab with KINTEK's advanced high-temperature furnace solutions. Our expertise in R&D and in-house manufacturing allows us to provide tailored systems like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, enhanced by deep customization to meet your unique experimental needs. Contact us today to discuss how we can optimize your gas dispersion and overall furnace performance!

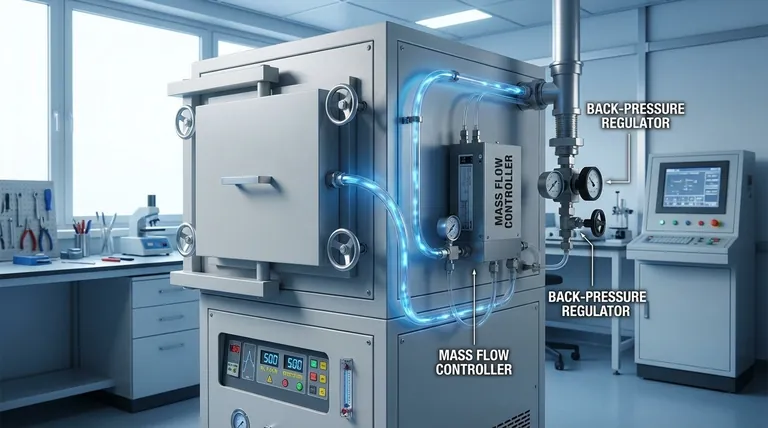

Visual Guide

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

- Ultra-High Vacuum Flange Aviation Plug Glass Sintered Airtight Circular Connector for KF ISO CF

- Ultra Vacuum Electrode Feedthrough Connector Flange Power Lead for High Precision Applications

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What is the use of nitrogen in furnace? Prevent Oxidation for Superior Heat Treatment

- What does inert mean in furnace atmospheres? Protect materials from oxidation with inert gases.

- What is the main purpose of heat treatment? Transform Metal Properties for Superior Performance

- How does an inert atmosphere prevent oxidation? Shield Materials from Oxygen Damage

- What are the environmental benefits of using inert gases in furnaces? Reduce Waste and Emissions for a Greener Process