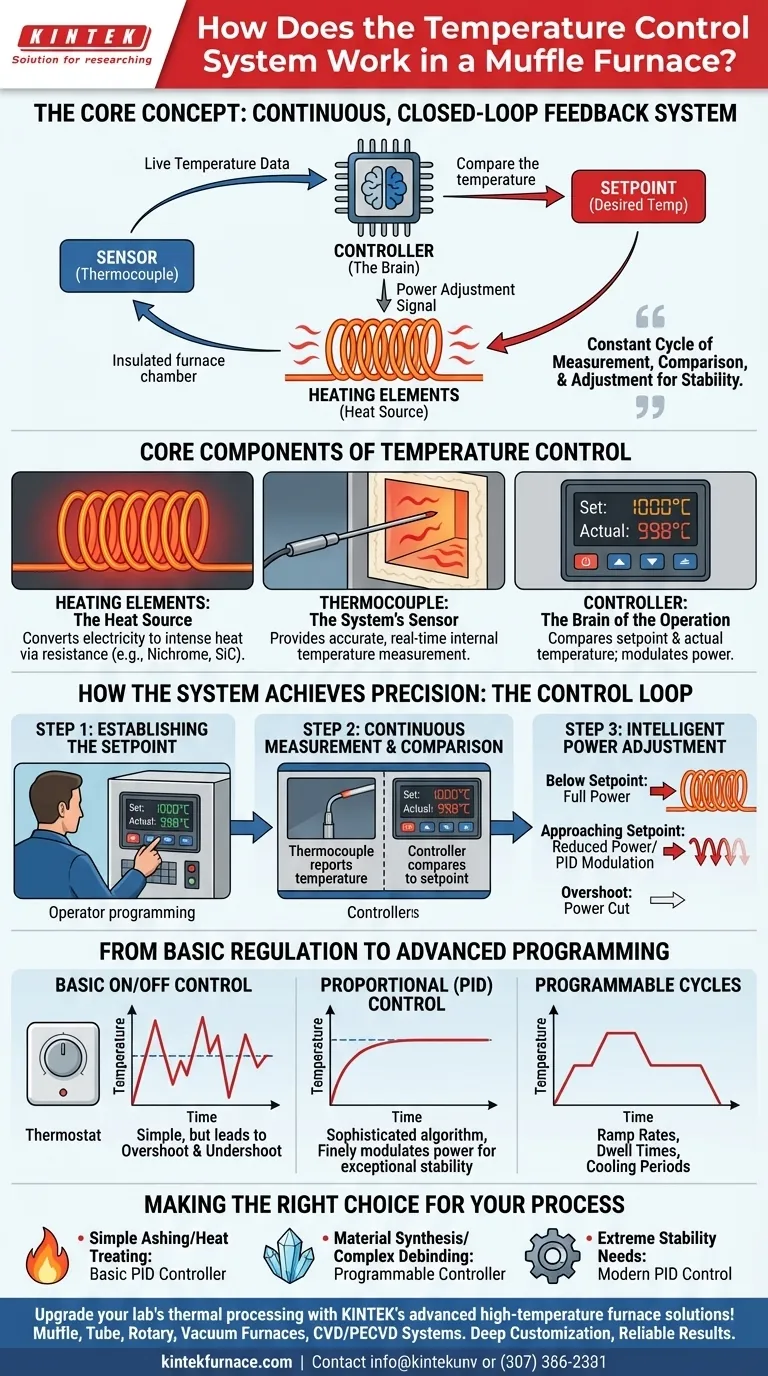

At its core, a muffle furnace's temperature control system works as a continuous, closed-loop feedback system. It uses a temperature sensor to constantly measure the internal chamber temperature, a controller to compare that measurement against a desired setpoint, and then intelligently adjusts the electrical power sent to the heating elements to maintain the target temperature with high precision.

The system's fundamental principle is simple yet powerful: a sensor tells a controller the actual temperature, and the controller adjusts power to the heating elements to precisely match your desired setting. This constant cycle of measurement, comparison, and adjustment is the key to stable and repeatable thermal processing.

The Core Components of Temperature Control

To understand the system, you must first understand its three critical components. Each has a distinct and essential role in achieving a stable temperature.

The Heating Elements: The Source of Heat

The process begins with the heating elements, typically made of materials like nichrome or silicon carbide wire, which line the chamber walls.

When an electrical current flows through these elements, their natural resistance causes them to generate intense heat. This heat is then transferred into the insulated chamber via radiation and convection.

The Thermocouple: The System's Sensor

A thermocouple is a robust temperature sensor inserted directly into the furnace chamber. Its job is to provide an accurate, real-time measurement of the actual temperature where your sample is located.

This sensor acts as the eyes of the control system, constantly sending live temperature data back to the controller for analysis.

The Controller: The Brain of the Operation

The controller is the central processing unit. It receives two key inputs: the desired temperature (the "setpoint") you program into it and the real-time temperature data from the thermocouple.

Its sole function is to compare these two values and decide what action to take, sending a signal to either increase, decrease, or maintain power to the heating elements.

How the System Achieves Precision: The Control Loop

The components work together in a dynamic, self-regulating cycle. This process ensures the furnace doesn't just get hot but reaches and holds the exact temperature required for your process.

Step 1: Establishing the Setpoint

The process is initiated by the operator, who enters a target temperature, known as the setpoint, into the controller.

Step 2: Continuous Measurement and Comparison

As the furnace heats up, the thermocouple continuously reports the chamber's temperature back to the controller. The controller constantly compares this actual temperature to the setpoint.

Step 3: Intelligent Power Adjustment

If the actual temperature is below the setpoint, the controller supplies full power to the heating elements. As the temperature approaches the setpoint, a smart controller begins to reduce the power.

If the temperature overshoots the setpoint, the controller cuts power entirely until the temperature falls back into the correct range. This constant modulation is what creates a stable thermal environment.

From Basic Regulation to Advanced Programming

Not all control systems are created equal. The sophistication of the controller dictates the precision and complexity of the heating profiles you can run.

Basic On/Off Control

The simplest controllers work like a basic thermostat. They turn the heating elements on at full power when the temperature is too low and completely off when it's too high. This method is effective but can lead to temperature "overshoot" and "undershoot" around the setpoint.

Proportional (PID) Control

Most modern digital furnaces use a PID (Proportional-Integral-Derivative) controller. This is a sophisticated algorithm that anticipates temperature changes.

Instead of just turning power on or off, it finely modulates the power level, reducing it as it nears the setpoint to prevent overshoot. This results in exceptionally smooth and stable temperature maintenance with minimal fluctuation.

Programmable Cycles

Advanced controllers are programmable, allowing you to define complex heating cycles. You can specify:

- Ramp rates: The speed at which the temperature rises (°C/minute).

- Dwell times: How long the furnace holds at a specific temperature.

- Cooling periods: Controlled rates of cooling for sensitive materials.

This level of control is essential for advanced materials science, metallurgy, and complex chemical reactions.

Making the Right Choice for Your Process

Understanding the control system helps you select the right furnace and use it effectively.

- If your primary focus is simple ashing or heat-treating at a single temperature: A furnace with a basic but reliable digital PID controller is perfectly sufficient.

- If your work involves material synthesis, crystal growth, or complex debinding: A furnace with a fully programmable controller is non-negotiable for defining precise ramp and dwell stages.

- If your results depend on extreme temperature stability with minimal fluctuation: Prioritize a furnace that explicitly features modern PID control to avoid the temperature cycling common with simpler on/off systems.

Understanding this control system empowers you to select the right tool and execute your thermal processes with confidence and repeatability.

Summary Table:

| Component | Function | Key Feature |

|---|---|---|

| Heating Elements | Generate heat via electrical resistance | Materials like nichrome or silicon carbide |

| Thermocouple | Measures real-time chamber temperature | Provides accurate sensor data |

| Controller | Compares setpoint with actual temperature, adjusts power | Uses PID for precision and stability |

| Control Type | Description | Best Use Case |

| On/Off Control | Turns elements on/off based on temperature | Simple processes like ashing |

| PID Control | Modulates power to prevent overshoot | High-stability applications |

| Programmable Cycles | Allows ramp rates, dwell times, cooling periods | Complex material synthesis |

Upgrade your lab's thermal processing with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable equipment like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental needs for superior temperature control and repeatable results. Contact us today to discuss how we can enhance your research and production efficiency!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals

- What is the role of a muffle furnace in the study of biochar regeneration and reuse? Unlock Sustainable Water Treatment

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency