In essence, a muffle furnace is a high-temperature oven used for a range of scientific and industrial processes that demand precise thermal control in a clean environment. Its primary applications include determining the non-combustible "ash" content of materials, performing heat treatments to alter the properties of metals, and processing materials like ceramics and glass.

The core value of a muffle furnace is not just its ability to get hot, but its design that separates the material being heated from the heating elements. This "muffle" creates a contaminant-free chamber, which is critical for analytical purity and advanced material processing.

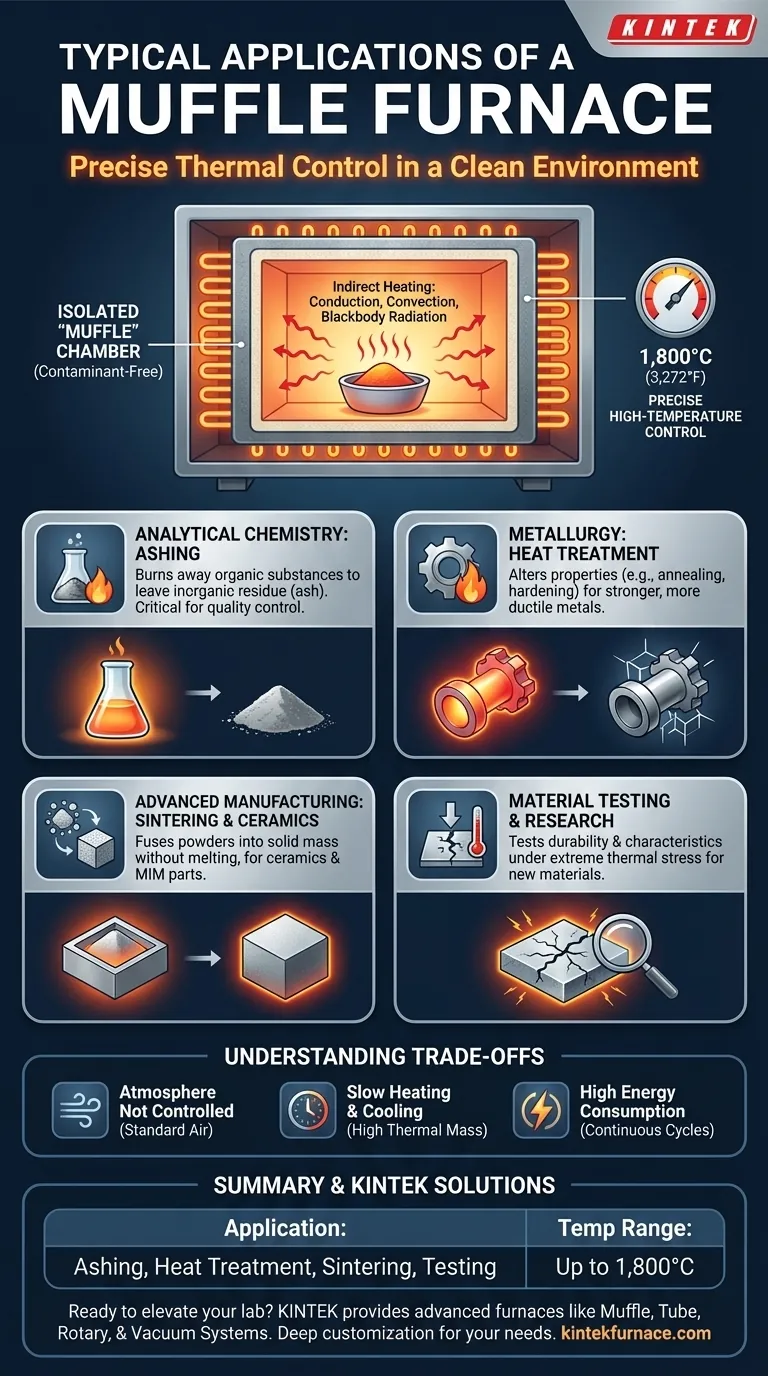

How a Muffle Furnace Achieves Its Purpose

Before diving into specific applications, it's crucial to understand why a muffle furnace is chosen for these tasks. Its unique design delivers two key benefits.

The Isolated "Muffle" Chamber

The defining feature is the insulated chamber—the muffle—that contains the sample. In modern electric furnaces, the heating elements are outside this chamber.

This design prevents any byproducts of combustion or contaminants from the heating elements from coming into contact with the sample. Heating is achieved indirectly through conduction, convection, and blackbody radiation, ensuring a pure environment.

Precise, High-Temperature Control

Muffle furnaces are engineered to reach and maintain very high temperatures, often up to 1,800°C (3,272°F).

This capability, combined with sophisticated temperature controllers, allows for uniform and highly repeatable heating cycles, which is essential for both manufacturing and scientific research.

Key Applications in Science and Industry

The furnace's unique capabilities make it indispensable across several fields for processes that cannot be done in a standard oven.

Analytical Chemistry: Ashing

Ashing is one of the most common laboratory applications. It involves heating a sample to a high temperature to burn away all organic substances.

This leaves behind only the inorganic, non-combustible residue, known as ash. Analyzing the weight and composition of this ash is a fundamental technique in material science, quality control, and regulatory testing.

Metallurgy: Heat Treatment

In metallurgy, heat treatment is used to alter the physical and mechanical properties of metals.

Processes like annealing, hardening, and tempering are performed in muffle furnaces to make metals stronger, more ductile, or more resistant to wear. The precise temperature control is critical for achieving the desired material structure.

Advanced Manufacturing: Sintering and Ceramics

Sintering is a process that uses heat to fuse powders into a solid mass without melting them. This is fundamental to creating ceramic components and parts made via metal injection molding (MIM).

Muffle furnaces provide the uniform, high-temperature environment needed for particles to bond correctly, forming a strong, dense final product. This is also used in the manufacturing of glass.

Material Testing and Research

Scientists and engineers use muffle furnaces to test the durability and characteristics of materials under extreme thermal stress.

This is vital in research and development for creating new alloys, composites, and coatings that can withstand high-temperature environments in industries like aerospace, cement, and nuclear power.

Understanding the Trade-offs

While powerful, a muffle furnace is a specialized tool with specific constraints that make it unsuitable for certain tasks.

Atmosphere is Not Controlled by Default

A standard muffle furnace operates with the air present in the chamber. Processes requiring a vacuum or a specific inert gas (like argon) need a specialized furnace designed for atmosphere control.

Slow Heating and Cooling Cycles

The heavy insulation required to safely reach and hold extreme temperatures gives the furnace significant thermal mass. This means they can be slow to heat up and, more importantly, very slow to cool down, impacting sample throughput.

High Energy Consumption

Achieving and maintaining temperatures over 1,000°C is an energy-intensive process. This is a significant operational consideration, especially for large industrial units running continuous cycles.

Making the Right Choice for Your Goal

To determine if a muffle furnace is the correct tool, consider your primary objective.

- If your primary focus is analytical purity: The furnace's isolated chamber is ideal for applications like ashing, where you must prevent contamination to get an accurate result.

- If your primary focus is altering material properties: The precise, uniform heat control is essential for repeatable heat treatment of metals and the proper firing of ceramics.

- If your primary focus is creating solid parts from powders: A muffle furnace's ability to hold a stable, high temperature is critical for successful sintering.

- If your primary focus is high throughput or rapid cycles: You may need to explore alternative heating technologies, as the thermal mass of a muffle furnace inherently limits its cycle speed.

Ultimately, understanding the core principle of isolated, high-temperature heating empowers you to leverage the muffle furnace for tasks that demand the highest levels of precision and purity.

Summary Table:

| Application | Key Use Case | Temperature Range |

|---|---|---|

| Analytical Chemistry | Ashing for inorganic residue analysis | Up to 1,800°C |

| Metallurgy | Heat treatment (annealing, hardening) | Up to 1,800°C |

| Advanced Manufacturing | Sintering of ceramics and metals | Up to 1,800°C |

| Material Testing | Durability and thermal stress research | Up to 1,800°C |

Ready to elevate your lab's capabilities with tailored high-temperature solutions? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere, and CVD/PECVD Systems. Our deep customization ensures they meet your unique experimental needs for precision and purity. Contact us today to discuss how our solutions can drive your research and production forward!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the function of a muffle furnace in SiCf/Al-Mg pretreatment? Optimize Fiber Bonding with Thermal De-sizing

- What is the primary function of a muffle furnace in iron-modified activated carbon prep? Optimize Adsorption Sites

- How does the use of a 100-mesh sieve contribute to the performance consistency of magnetic chitosan carbon?

- What is the purpose of heating a precursor solution to 80 °C and 300 rpm stirring? Achieve High-Entropy Uniformity

- What key step does a Muffle Furnace perform in the determination of mineral content in Tenebrio molitor larvae?