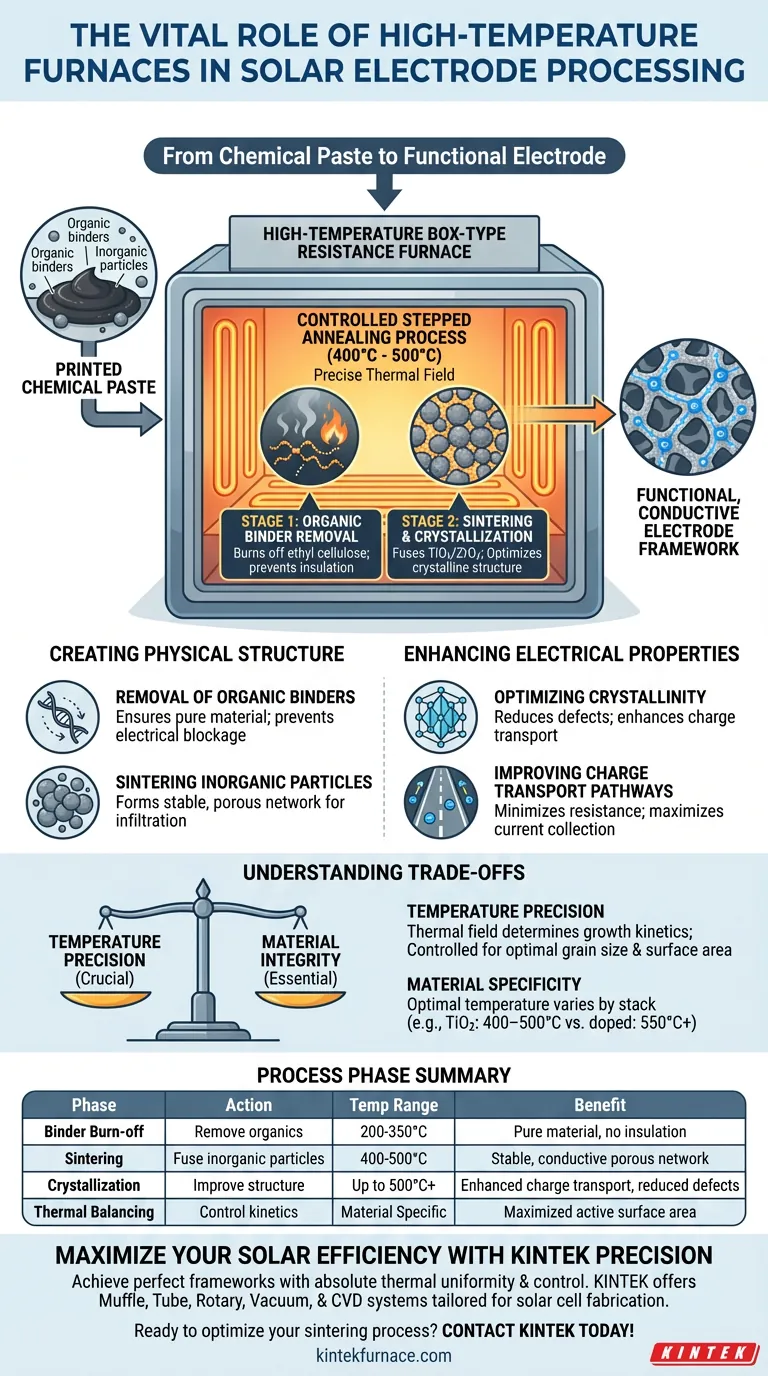

A high-temperature box-type resistance furnace is the critical processing tool used to transform printed chemical pastes into functional, conductive solar cell electrodes. By executing a controlled, stepped annealing process at temperatures reaching 400°C to 500°C, the furnace removes organic binders and fuses inorganic particles into a stable, porous network required for energy conversion.

The furnace serves as a bridge between raw material application and final device functionality. Its primary role is to eliminate organic additives while simultaneously crystallizing materials like titanium dioxide, ensuring the electrode possesses both the physical porosity and the electrical conductivity necessary for high-performance solar cells.

Creating the Physical Structure

Removal of Organic Binders

In the initial stages of electrode fabrication, materials are often applied as pastes containing organic binders, such as ethyl cellulose.

The furnace provides the thermal environment necessary to burn off these organics completely. Without this step, residual organics would insulate the particles, blocking electrical flow and degrading device performance.

Sintering Inorganic Particles

Once the binders are removed, the furnace facilitates the sintering of the remaining inorganic particles.

This process fuses nanoparticles of titanium dioxide, zirconium dioxide, or carbon together without melting them completely. The result is a mechanically stable network that retains the porosity required for electrolyte infiltration or hole-conductor deposition.

Enhancing Electrical Properties

Optimizing Crystallinity

Beyond simple drying, the high temperatures (up to 500°C) drive the crystallization of the semiconductor materials.

For materials like titanium dioxide, this thermal treatment enhances the crystalline structure. High-quality crystallinity is non-negotiable for reducing defects that can trap electrons and reduce voltage.

Improving Charge Transport Pathways

The furnace effectively creates the "highway" for electron movement within the solar cell.

By optimizing the connections between particles through sintering and improved crystallinity, the furnace ensures efficient interfacial charge transport. This minimizes resistance and maximizes the current collected from the solar cell.

Understanding the Trade-offs

Temperature Precision vs. Material Integrity

While high heat is necessary, the thermal field within the furnace must be precisely controlled.

As seen in similar calcination processes (such as with nickel oxide), the thermal field determines growth kinetics. If the temperature is too low, organic binders may remain; if it is too high or uncontrolled, the grain size may grow too large, reducing the surface area essential for chemical reactions.

Material Specificity

The optimal annealing temperature is strictly dependent on the specific material stack being processed.

For example, while titanium dioxide frameworks often require 400–500°C, other precursors (like certain doped nanopowders) might require distinct temperatures (e.g., 550°C to 850°C) to achieve specific crystalline phases, such as Face-Centered Cubic (FCC) structures. One thermal profile does not fit all.

Making the Right Choice for Your Goal

To maximize the utility of a high-temperature box furnace in your solar cell production, align your thermal profile with your specific material requirements:

- If your primary focus is Structural Stability: Ensure your annealing stages are stepped gradually to allow the full burnout of ethyl cellulose binders before high-temperature sintering begins, preventing cracks in the porous network.

- If your primary focus is Electrical Efficiency: Prioritize the upper range of the safe temperature window (e.g., near 500°C for TiO2) to maximize crystallinity and reduce internal resistance, ensuring the best possible charge transport.

Success in solar electrode fabrication relies not just on the materials you choose, but on the precision with which you sinter them.

Summary Table:

| Process Phase | Primary Action | Key Temperature Range | Resulting Benefit |

|---|---|---|---|

| Binder Burn-off | Removal of organics (e.g., ethyl cellulose) | 200°C - 350°C | Prevents insulation; ensures pure material |

| Sintering | Fusing inorganic nanoparticles | 400°C - 500°C | Creates stable, conductive porous network |

| Crystallization | Improving semiconductor structure | Up to 500°C+ | Enhances charge transport & reduces defects |

| Thermal Balancing | Grain size & kinetics control | Material Specific | Maximizes active surface area for reactions |

Maximize Your Solar Efficiency with KINTEK Precision

Achieving the perfect porous framework requires more than just heat; it requires absolute thermal uniformity and control. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems tailored for the rigorous demands of solar cell fabrication. Whether you need standard lab high-temp furnaces or fully customizable solutions for unique material stacks, we provide the technology to ensure your electrodes achieve peak crystallinity and conductivity.

Ready to optimize your sintering process? Contact KINTEK today to discuss your custom furnace requirements!

Visual Guide

References

- Takaya Shioki, Seigo Ito. Designed Mesoporous Architecture by 10–100 nm TiO2 as Electron Transport Materials in Carbon-Based Multiporous-Layered-Electrode Perovskite Solar Cells. DOI: 10.3390/photonics11030236

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What is the role of an industrial box resistance furnace in the conversion of basic copper chloride to copper oxide?

- What types of box furnaces are available based on power source? Choose Electric or Gas for Your Needs

- How does a muffle furnace convert goethite to hematite? Unlock Precision Thermal Dehydration

- What factors should be considered when choosing a muffle furnace? Select the Perfect Fit for Your Lab

- How does a high-temperature box furnace contribute to the accuracy of oxidation kinetics experiments? Achieve Precision

- How are muffle furnaces critical in the semiconductor industry? Essential for Precise Thermal Processing in Chip Fabrication

- What thermal processes can be performed using Box Furnaces? Unlock Versatile Heat Treatment Solutions

- What materials are recommended for muffle furnace construction? Optimize for High-Temp Performance and Safety