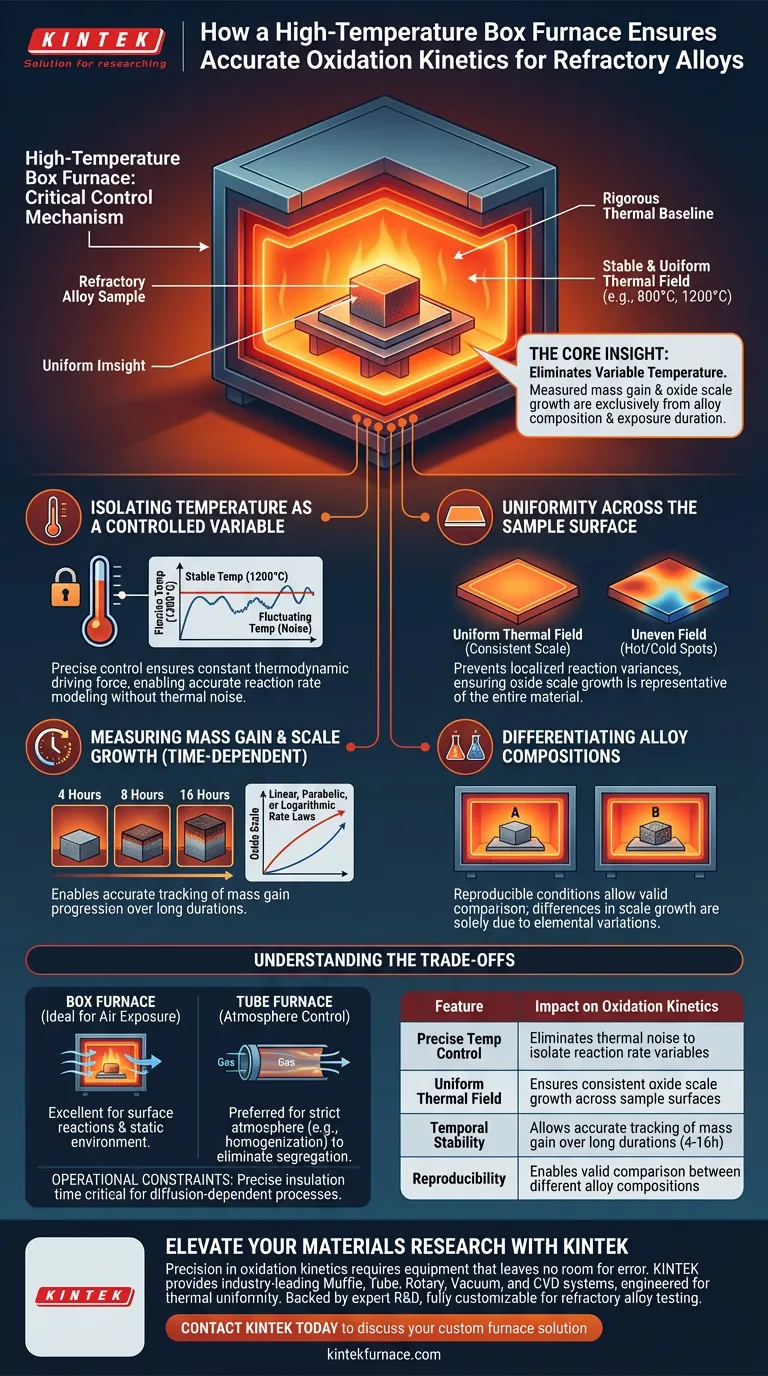

A high-temperature box furnace functions as the critical control mechanism in oxidation kinetics experiments by establishing a rigorous thermal baseline. It provides the stable and uniform thermal field necessary for air exposure tests at elevated temperatures, such as 800°C and 1200°C. This stability ensures that temperature remains a fixed constant, preventing thermal fluctuations from invalidating data regarding reaction rates.

The Core Insight In the study of refractory alloys, variable temperature ruins kinetic data. A high-temperature box furnace eliminates this variable, ensuring that measured mass gain and oxide scale growth are exclusively the result of alloy composition and exposure duration.

The Role of Thermal Stability in Kinetic Analysis

Isolating Temperature as a Controlled Variable

To accurately study kinetics, researchers must isolate specific variables. The precise temperature control system of a box furnace ensures that heat does not fluctuate during the experiment.

By locking the temperature at a specific set point (e.g., 1200°C), the furnace ensures that the thermodynamic driving force remains constant. This allows the researcher to mathematically model the reaction rate without noise from thermal instability.

Uniformity Across the Sample Surface

A box furnace is designed to create a uniform thermal field within the chamber. This prevents "hot spots" or "cold spots" on the alloy sample.

If the thermal field were uneven, different parts of the refractory alloy would oxidize at different rates. Uniformity ensures that the oxide scale growth observed is representative of the entire material.

Measuring Mass Gain and Scale Growth

Enabling Time-Dependent Comparisons

Oxidation kinetics studies rely heavily on time-based data points. The furnace maintains stability over varying durations, such as 4, 8, or 16 hours.

This endurance allows researchers to track the progression of mass gain accurately. It reveals whether the oxidation follows a linear, parabolic, or logarithmic rate law over time.

Differentiating Alloy Compositions

When testing different alloy compositions, the environment must be identical for valid comparison. The box furnace provides this standardized environment for air exposure.

Because the thermal conditions are reproducible, any difference in oxide scale growth patterns can be definitively attributed to the elemental differences in the alloys, rather than environmental inconsistencies.

Understanding the Trade-offs

Specificity of Application

While box furnaces are ideal for the air exposure method mentioned in oxidation studies, they have specific use cases compared to other equipment.

For example, high-temperature tube furnaces are often preferred for processes requiring strict atmosphere control (like homogenization annealing) to eliminate segregation.

Operational Constraints

The box furnace excels at maintaining a static environment for surface reactions. However, for processes requiring atomic diffusion to reach thermodynamic equilibrium inside the matrix (such as solutionizing), precise insulation time is critical to prevent over-aging or incomplete phase dissolution.

Making the Right Choice for Your Goal

To ensure your experimental setup matches your research objectives, consider the following:

- If your primary focus is determining oxidation rates: Use the box furnace to maintain a rigorous constant temperature, allowing you to plot accurate mass gain against time.

- If your primary focus is comparing alloy durability: Rely on the furnace's uniform thermal field to test multiple compositions simultaneously under identical air exposure conditions.

Ultimately, the high-temperature box furnace transforms heat from an unpredictable environmental factor into a precise analytical tool.

Summary Table:

| Feature | Impact on Oxidation Kinetics |

|---|---|

| Precise Temp Control | Eliminates thermal noise to isolate reaction rate variables |

| Uniform Thermal Field | Ensures consistent oxide scale growth across sample surfaces |

| Temporal Stability | Allows accurate tracking of mass gain over long durations (4-16h) |

| Reproducibility | Enables valid comparison between different alloy compositions |

Elevate Your Materials Research with KINTEK

Precision in oxidation kinetics requires equipment that leaves no room for error. KINTEK provides industry-leading Muffle, Tube, Rotary, Vacuum, and CVD systems, all engineered to deliver the thermal uniformity your experiments demand. Backed by expert R&D and manufacturing, our high-temperature lab furnaces are fully customizable to meet the unique challenges of refractory alloy testing and advanced heat treatment.

Ready to transform heat into a precise analytical tool?

Contact KINTEK today to discuss your custom furnace solution.

Visual Guide

References

- High-Temperature Oxidation and Thermal Expansion Behavior of NbTi–X (X = 5Co, 10Cr, 10Ni, 10CoCrNi) Refractory Medium Entropy Alloys. DOI: 10.1007/s11661-025-07911-4

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What is the significance of using a box-type furnace for molybdenum aluminide coating oxidation? Master Thermal Testing

- What are the primary applications of muffle furnaces? Essential for Material Analysis and Heat Treatment

- How are muffle furnaces used in glassmaking? Achieve Clean, Controlled Heat for Superior Glass Quality

- Why is precise temperature control in a muffle furnace essential during the secondary calcination of acid-etched catalysts?

- What should be considered when choosing a muffle furnace for specific needs? Key Factors for Optimal Lab Performance

- How is a muffle furnace utilized for AlN crystal post-processing? Optimize Surface Purity via Staged Oxidation

- What is the principle of muffle furnace in laboratory? Achieving Pure, Contaminant-Free Heating

- What is the significance of the muffle furnace heat treatment in Si@Sn@C preparation? Unlock Structural Stability