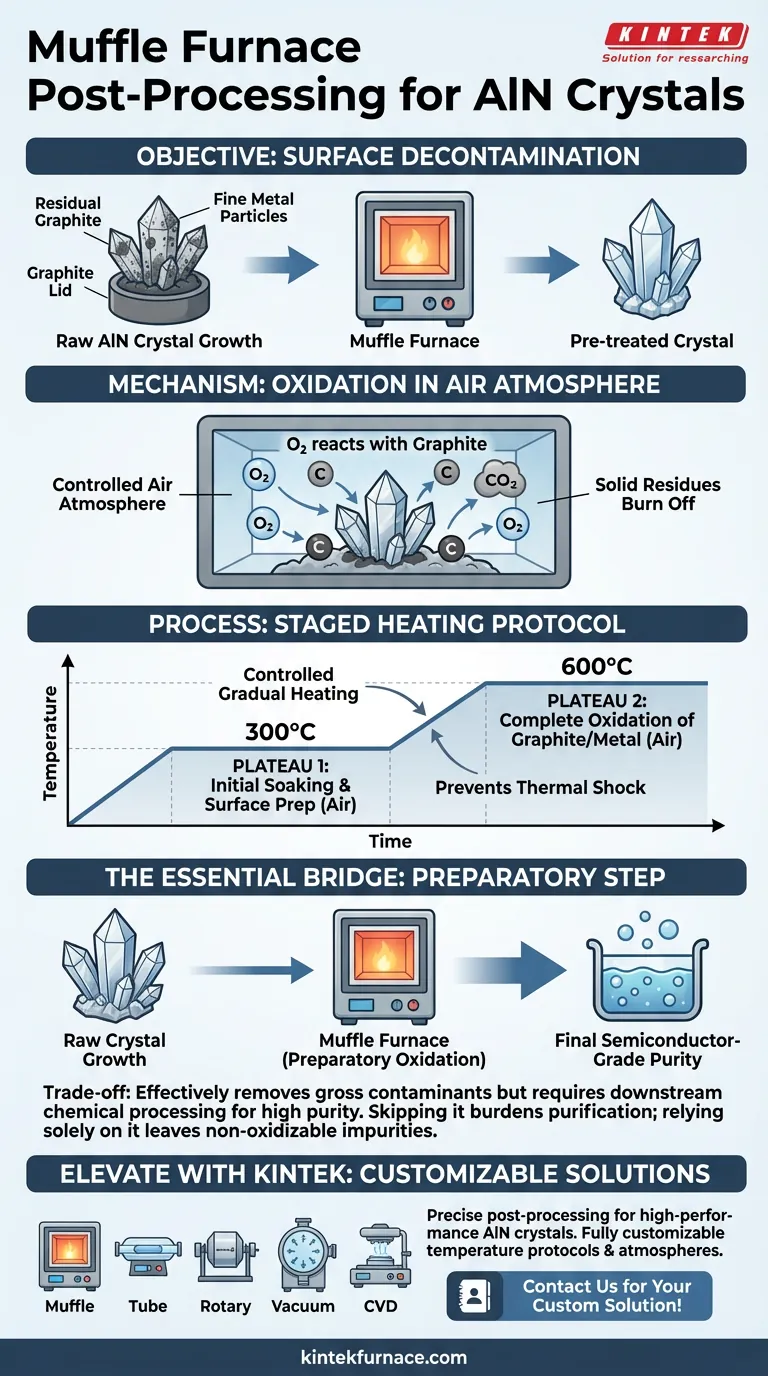

Post-processing Aluminum Nitride (AlN) crystals utilizes a muffle furnace to perform a critical thermal cleaning step immediately following the growth cycle. By subjecting the crystals—still contained within their graphite lid—to staged heating in an air atmosphere, the furnace oxidizes and removes surface contaminants like residual graphite and fine metal particles.

Core Takeaway The muffle furnace serves as a preparatory oxidation stage, using an air atmosphere and specific temperature plateaus (300°C and 600°C) to strip away solid residues, ensuring the crystals are clean enough for subsequent chemical purification.

The Objective: Removing Post-Growth Residues

The primary function of the muffle furnace in this context is surface decontamination.

Targeting Specific Contaminants

After the growth phase, AlN crystals are not immediately ready for use. They are often coated with residual graphite particles and fine metal residues.

These contaminants usually originate from the growth environment, specifically the graphite lid and vessel used during the process.

The Mechanism of Oxidation

The furnace operates using an air atmosphere. This is a functional requirement, not just a passive environment.

The oxygen in the air reacts with the carbon-based graphite residues at high temperatures. This causes the graphite to oxidize (burn off), effectively detaching it from the crystal surface.

The Process: Staged Heating Protocol

Effectively cleaning AlN crystals requires a controlled thermal profile rather than a single blast of heat.

Utilizing Temperature Plateaus

The process employs staged heating. The primary reference highlights two specific temperature checkpoints: 300°C and 600°C.

Thermal Soaking

By holding the crystals at these specific temperatures, the furnace ensures complete oxidation of different types of residues without thermally shocking the crystals.

This staged approach gradually eliminates contaminants, preparing the surface for the next phase of the workflow.

Understanding the Trade-offs

While the muffle furnace is essential, it is important to recognize the limitations of this specific step.

Thermal Treatment is Not Total Purification

The muffle furnace is a preparatory tool, not the final solution.

While it effectively removes gross surface contaminants through oxidation, it does not achieve semiconductor-grade purity on its own. It is designed to facilitate, not replace, the downstream processes.

Dependency on Chemical Processing

The heat treatment prepares the crystals for subsequent chemical purification steps.

Skipping the muffle furnace step would likely burden the chemical purification stage with excessive solid residues, potentially reducing its efficiency. Conversely, relying solely on the furnace would leave non-oxidizable impurities behind.

Making the Right Choice for Your Goal

To maximize the yield and quality of your AlN crystals, consider how this thermal step fits into your wider processing line.

- If your primary focus is Process Efficiency: Ensure your furnace is programmed for staged heating at 300°C and 600°C to maximize the oxidation of graphite residues.

- If your primary focus is Crystal Purity: View the furnace as a pre-treatment step that is mandatory to protect the efficacy of your final chemical purification baths.

The muffle furnace acts as the essential bridge between raw crystal growth and high-purity chemical finishing.

Summary Table:

| Process Stage | Temperature | Purpose | Atmosphere |

|---|---|---|---|

| First Plateau | 300°C | Initial thermal soaking and surface preparation | Air |

| Second Plateau | 600°C | Complete oxidation of residual graphite and metal particles | Air |

| Final Step | Variable | Transition to chemical purification for semiconductor-grade purity | N/A |

Elevate Your Crystal Purity with KINTEK

Precise post-processing is critical for high-performance Aluminum Nitride crystals. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems—all fully customizable to meet your specific temperature protocols and atmosphere requirements.

Whether you need staged heating for oxidation or advanced vacuum environments for material synthesis, our lab high-temp furnaces provide the thermal stability your research demands.

Ready to optimize your post-growth workflow? Contact us today to discuss your custom furnace solution!

Visual Guide

References

- Xiaochun Tao, Zhanggui Hu. Growth of Spontaneous Nucleation AlN Crystals by Al-Base Alloy Evaporation in Nitrogen Atmosphere. DOI: 10.3390/cryst14040331

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What is the role of an industrial box resistance furnace in the conversion of basic copper chloride to copper oxide?

- What is the specific application of a high-temperature box resistance furnace for TiBw/TA15? Master Thermal Prepping

- What role do muffle furnaces play in pharmaceutical research and development? Essential for Quality Control and Innovation

- What is the purpose of a muffle furnace? Achieve Contamination-Free High-Temperature Processing

- What necessary process conditions does a muffle furnace provide for fruit powder ash analysis? Mastering 550°C Oxidation

- What are the key features of box furnaces? Versatile Thermal Solutions for Labs and Industry

- What makes muffle furnaces particularly useful for sensitive materials? Ensure Precision, Purity & Protection

- What are some common applications of box furnaces? Versatile Solutions for Metal Heat Treatment and Material Processing