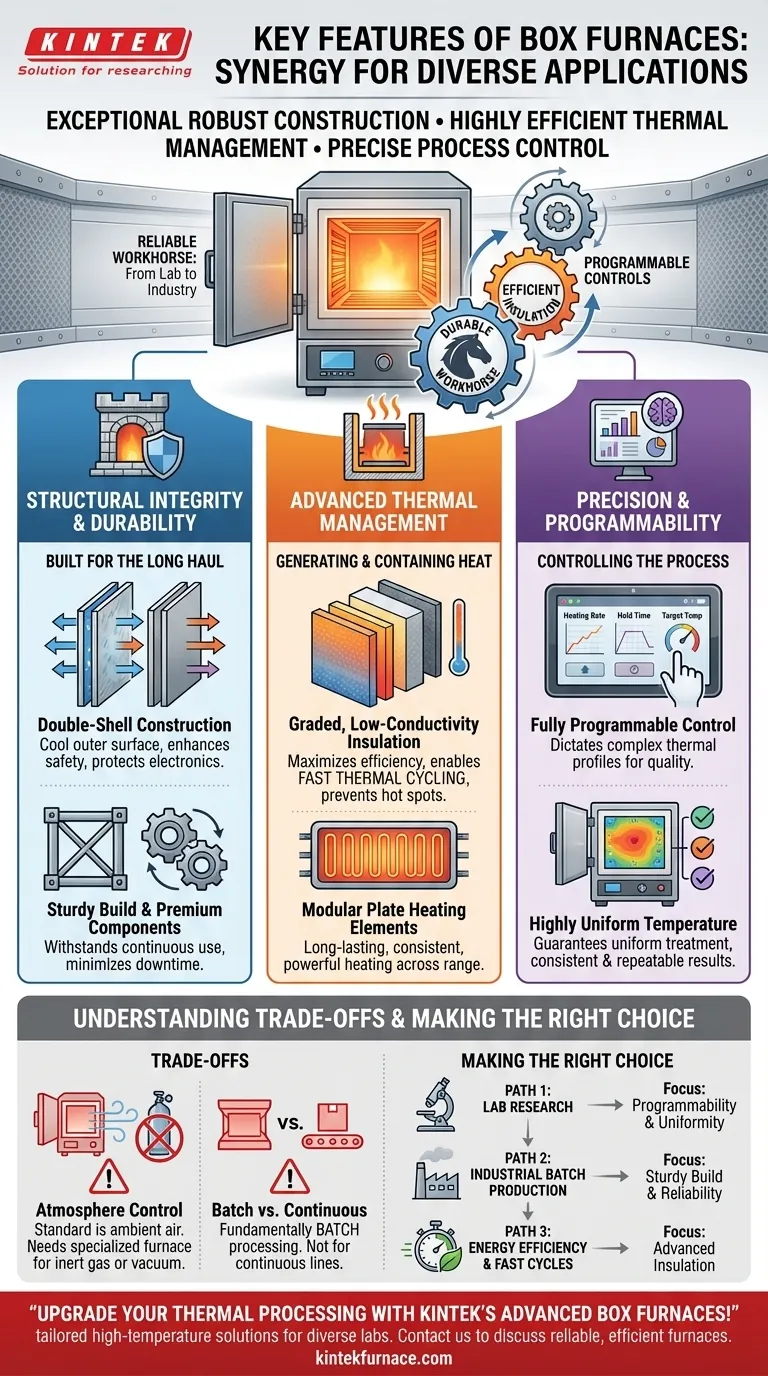

At their core, box furnaces are defined by a synthesis of three key characteristics: exceptionally robust construction, highly efficient thermal management, and precise process control. These features are not independent but work in concert, making the box furnace a versatile and reliable tool suitable for everything from delicate laboratory work to demanding industrial production.

The true value of a box furnace lies not in a single feature, but in the synergy between its durable build, efficient insulation, and programmable controls. This combination creates a reliable workhorse for a vast range of thermal processing tasks, from heat treating steel to manufacturing electronics.

The Foundation: Structural Integrity and Durability

The longevity and reliability of a box furnace begin with its physical construction. These are not delicate instruments but robust pieces of industrial equipment designed for years of service.

Double-Shell Construction

Many high-quality box furnaces feature a double-shell construction. This design creates an air gap that keeps the outer surface of the furnace cooler, enhancing operator safety and protecting sensitive internal electronics from heat degradation.

Sturdy Build and Premium Components

Their reputation is built on extra-sturdy frames and the use of premium, highly reliable components. This focus on build quality ensures they can withstand the rigors of continuous industrial use, minimizing downtime and maintenance costs over the equipment's lifespan.

The Core Function: Advanced Thermal Management

A furnace's primary job is to generate and contain heat effectively. Modern box furnaces achieve this through sophisticated insulation and heating element design.

Graded, Low-Conductivity Insulation

Box furnaces utilize advanced insulation systems with extremely low thermal conductivity. This design achieves two critical goals: it maximizes energy efficiency and enables fast thermal cycling (rapid heating and cooling).

This graded insulation also prevents the formation of hot spots at high temperatures, ensuring uniform heat distribution and preventing premature degradation of the furnace chamber.

Modular Plate Heating Elements

The heating elements are the heart of the furnace. Many models use long-lasting modular plate elements, which are known for their durability and ability to bypass normal watt-loading limitations. This results in consistent, powerful, and reliable heating performance across the furnace's entire temperature range.

The Brains: Precision and Programmability

Raw power is useless without control. The ability to precisely manage the thermal process is what makes a box furnace adaptable to so many different materials and applications.

Fully Programmable Control

Modern units come with fully programmable controllers. This allows operators to precisely dictate heating and cooling rates, hold times, and target temperatures.

This level of control is essential for complex processes like annealing alloys, tempering steel, or firing sensitive electronic components, where the thermal profile directly impacts the quality of the final product.

Highly Uniform Temperature

A key performance metric is temperature uniformity. Through a combination of quality insulation and strategic element placement, box furnaces provide a highly uniform temperature throughout the entire chamber. This guarantees that every part of a batch receives the exact same thermal treatment, leading to consistent and repeatable results.

Understanding the Trade-offs

No single piece of equipment is perfect for every task. Understanding a box furnace's inherent limitations is crucial for making the right choice.

Limitation 1: Atmosphere Control

A standard box furnace operates using the ambient air in the room. If your process requires a specific environment, such as an inert gas (like argon or nitrogen) or a vacuum, you will need a specialized furnace designed for atmosphere control.

Limitation 2: Batch vs. Continuous Processing

Box furnaces are fundamentally batch processing units. You load a batch of material, run the thermal cycle, and then unload it. For high-volume, continuous manufacturing lines, a conveyor or tunnel furnace is a far more efficient solution.

Making the Right Choice for Your Application

Selecting the right furnace depends entirely on your primary goal.

- If your primary focus is laboratory research or process development: The programmability and excellent temperature uniformity are your most critical features.

- If your primary focus is industrial reliability for batch production: The sturdy build, double-shell construction, and durable heating elements ensure long-term, dependable performance.

- If your primary focus is energy efficiency and fast cycle times: The advanced, low-conductivity insulation system is the key feature that will deliver the most value.

Understanding how these core features align with your specific thermal processing needs is the key to making an informed investment.

Summary Table:

| Feature | Description | Key Benefit |

|---|---|---|

| Structural Integrity | Double-shell construction, sturdy frames, premium components | Enhanced safety, durability, and long-term reliability |

| Thermal Management | Graded insulation, modular plate heating elements | Fast thermal cycling, uniform heating, energy efficiency |

| Precision Control | Fully programmable controllers, high temperature uniformity | Accurate process control for consistent, repeatable results |

| Limitations | Standard models lack atmosphere control; batch processing only | May require specialized furnaces for specific environments or continuous use |

Upgrade your thermal processing with KINTEK's advanced box furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored high-temperature solutions. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization to meet your unique experimental needs. Contact us today to discuss how our reliable, efficient furnaces can enhance your lab's performance and achieve precise results!

Visual Guide

Related Products

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What are the key features of a quartz tube furnace? Discover High-Temp Precision for Your Lab

- How should a quartz tube furnace be cleaned? Essential Steps for Safe, Contamination-Free Maintenance

- How does sample handling differ between vertical and horizontal tube furnaces? Choose the Right Furnace for Your Lab

- What is the use of a quartz tube furnace? For High-Purity, Observable Material Processing

- What are the common applications of quartz tube furnaces? Unlock Precision in High-Temp Processing