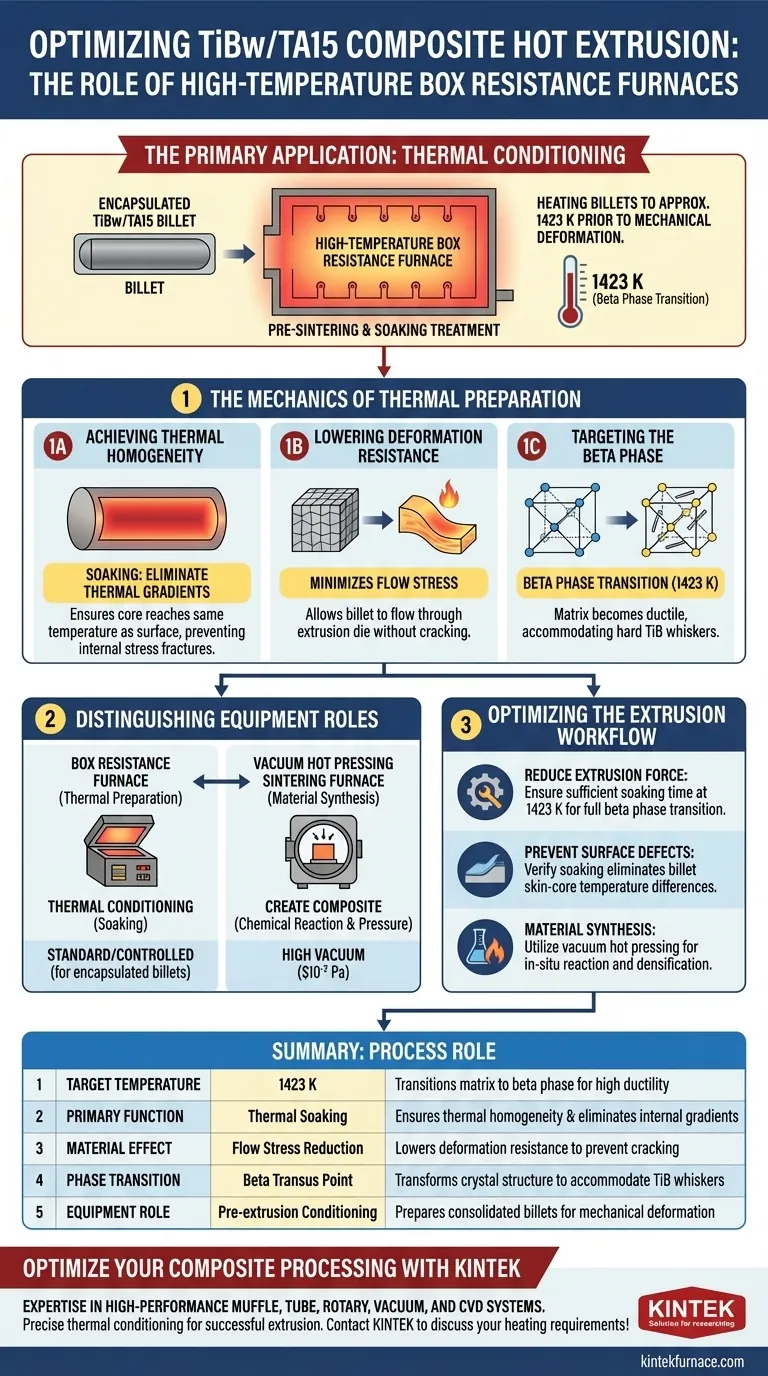

The primary application of a high-temperature box resistance furnace in this context is to thermally condition the TiBw/TA15 composite billets immediately prior to mechanical deformation. Specifically, it is used for the pre-sintering and soaking treatment of the encapsulated billets, typically heating them to approximately 1423 K.

Core Insight The furnace acts as a thermal equalizer, raising the billet's temperature above its beta phase transition point. This critical step minimizes the material's deformation resistance, transforming the rigid composite into a pliable state capable of withstanding the intense shear forces of hot extrusion.

The Mechanics of Thermal Preparation

Achieving Thermal Homogeneity

The box resistance furnace provides a stable environment for soaking the composite billets.

Soaking is not merely heating; it is the process of holding the material at a specific temperature until the thermal gradient is eliminated.

This ensures that the core of the billet reaches the same temperature as the surface, preventing internal stress fractures during processing.

Lowering Deformation Resistance

The primary goal of this heating stage is to prepare the material for physical shape change.

By heating the TiBw/TA15 composite to 1423 K, the furnace significantly lowers the flow stress of the material.

This reduction in resistance allows the billet to flow through the extrusion die without cracking or stalling the machinery.

Targeting the Beta Phase

The specific temperature of 1423 K is chosen to push the titanium matrix above its beta phase transition point.

In the beta phase, the crystal structure of the titanium alloy changes, becoming significantly more ductile.

This phase transformation is essential for accommodating the hard TiB whiskers (reinforcements) within the softer matrix during the extrusion flow.

Distinguishing Equipment Roles

Pre-Heating vs. Consolidation

It is vital to distinguish the role of the box resistance furnace from that of a vacuum hot pressing sintering furnace.

The vacuum furnace (mentioned in supplementary data) is used earlier in the lifecycle to create the composite through chemical reactions and pressure (e.g., 1473 K, 25 MPa).

In contrast, the box resistance furnace does not generate the reinforcement phase or apply pressure; it is purely a thermal preparation tool for an already-consolidated billet.

Atmosphere and Pressure Differences

The vacuum furnace operates at high vacuum ($10^{-2}$ Pa) to prevent oxidation during the long sintering process.

The box resistance furnace described here focuses on heating encapsulated billets.

Because the billets are encapsulated, the furnace does not necessarily require the high-vacuum environment used during the initial sintering phase.

Optimizing the Extrusion Workflow

To ensure the highest quality TiBw/TA15 profiles, you must apply the correct thermal treatment based on your processing stage.

- If your primary focus is reducing extrusion force: Ensure the box resistance furnace holds the billet at 1423 K long enough to fully transition the matrix to the beta phase.

- If your primary focus is preventing surface defects: Verify that the "soaking" period is sufficient to eliminate any temperature differences between the billet skin and core.

- If your primary focus is material synthesis: Do not rely on the box furnace; utilize vacuum hot pressing to facilitate the in-situ reaction and densification.

Proper thermal soaking transforms the composite from a brittle solid into a workable material, serving as the essential gateway to successful hot extrusion.

Summary Table:

| Process Feature | Specification / Detail | Role in TiBw/TA15 Extrusion |

|---|---|---|

| Target Temperature | 1423 K | Transitions matrix to beta phase for high ductility |

| Primary Function | Thermal Soaking | Ensures thermal homogeneity and eliminates internal gradients |

| Material Effect | Flow Stress Reduction | Lowers deformation resistance to prevent cracking |

| Phase Transition | Beta Transus Point | Transforms crystal structure to accommodate TiB whiskers |

| Equipment Role | Pre-extrusion Conditioning | Prepares consolidated billets for mechanical deformation |

Optimize Your Composite Processing with KINTEK

Precise thermal conditioning is the difference between a successful extrusion and a fractured billet. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems designed to meet the rigorous demands of aerospace and materials science.

Our lab high-temperature furnaces provide the thermal stability and accuracy required for beta-phase soaking and pre-sintering of advanced TiBw/TA15 composites. Whether you need a standard box resistance furnace or a fully customizable system tailored to your unique research needs, KINTEK delivers the reliability your lab deserves.

Ready to enhance your material properties and lab efficiency? Contact KINTEK today to discuss your heating requirements!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is a benchtop furnace and its common types? Choose the Right One for Your Lab

- What materials are used in muffle furnace construction? Key Materials for High-Temp Performance

- What is the primary function of a muffle furnace in birnessite preparation? Optimize High-Temp Calcination Control

- What is the role of high-temperature furnaces in 3D-printed glass debinding? Mastering the Silica Foundation

- What are the main benefits of using muffle furnaces? Achieve Purity and Precision in Heat Treatment

- What role does a high-temperature muffle furnace play in the component analysis of Moringa oleifera seeds?

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production

- How does the calcination process in a precision muffle furnace affect CuO nanoparticles? Optimize Your Synthesis.