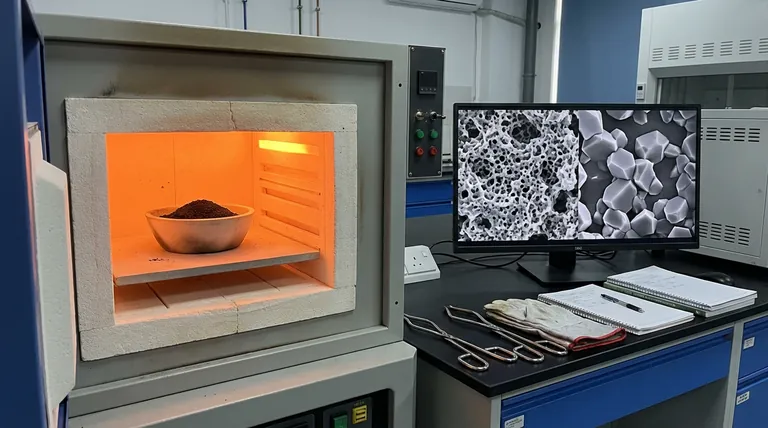

The calcination process acts as the critical bridge between raw precursors and functional copper oxide (CuO) nanoparticles. Typically conducted at 400°C in a precision muffle furnace, this thermal treatment triggers the crystalline transformation of precursors into stable oxides while simultaneously removing impurities.

Core Takeaway Calcination is not merely about drying; it is a structural engineering process. By driving off residual gases and organic matter, the furnace creates a porous, sponge-like morphology that maximizes specific surface area, directly enhancing the material's catalytic activity.

Mechanisms of Transformation

Crystalline Phase Formation

The primary function of the muffle furnace is to provide a stable high-temperature environment that facilitates thermal decomposition.

During this phase, amorphous precursors (such as hydroxides) undergo a chemical conversion. They transform into stable, monoclinic copper oxide (CuO) nanoparticles. This is the moment the material gains its defining semiconductor properties.

Purification via Oxidation

The constant high-temperature environment serves as a purification stage.

It effectively oxidizes and removes residual organic components, particularly those remaining from plant extracts used in synthesis. This ensures the final nanoparticle powder is chemically pure and free of carbonaceous residues that could inhibit performance.

Structural Evolution and Porosity

Creation of Sponge-Like Morphology

According to primary technical data, the physical structure of the nanoparticle changes drastically during calcination.

As the material heats, residual gases trapped within the precursor are forced to escape. This outgassing process creates a porous, sponge-like structure within the nanoparticles.

Enhancement of Surface Area

The formation of this porous architecture has a direct functional benefit.

It significantly increases the specific surface area of the CuO nanoparticles. A larger surface area exposes more active sites, which substantially enhances the material's catalytic activity.

Controlling Grain Growth

Regulating Particle Size

While the primary reaction often occurs at 400°C, the precision of the muffle furnace allows for control over grain size through temperature adjustment.

Research indicates that as temperatures rise from 400°C to 750°C, atomic diffusion and grain boundary migration accelerate. This causes CuO grains to grow from approximately 21 nm to 72 nm.

Morphology Transitions

Temperature control also dictates the shape of the crystals.

At lower calcination temperatures, particles may appear rounded and semi-amorphous. As heat increases, these transition into distinct crystalline structures with sharp edges. This morphological shift improves the electronic transport quality of the films, though it alters the surface profile.

Understanding the Trade-offs

Surface Area vs. Crystallinity

There is a fundamental trade-off between catalytic potential and electronic stability.

Lower temperatures (around 400°C) favor the "sponge-like," high-surface-area structure ideal for catalysis. However, higher temperatures (up to 750°C) produce larger, more distinct crystals with better electronic transport properties but potentially lower surface area.

The Risk of Over-Calcination

Excessive heat or prolonged soak times can lead to aggressive grain growth.

If the grains grow too large, the specific surface area diminishes, potentially reducing the material's effectiveness in surface-dependent applications like chemical sensing or catalysis.

Making the Right Choice for Your Goal

The optimal calcination protocol depends entirely on the intended application of your copper oxide nanoparticles.

- If your primary focus is Catalytic Activity: Maintain calcination near 400°C to preserve the porous, sponge-like structure and maximize specific surface area.

- If your primary focus is Electronic Transport: Increase the temperature (towards 750°C) to promote grain growth and achieve sharp, well-defined crystalline edges.

Precise control of the muffle furnace temperature allows you to tune the material's physical architecture to match its functional purpose.

Summary Table:

| Feature | Low Temp (approx. 400°C) | High Temp (up to 750°C) |

|---|---|---|

| Morphology | Porous, Sponge-like | Sharp, Distinct Crystals |

| Grain Size | Small (≈21 nm) | Large (≈72 nm) |

| Surface Area | High Specific Surface Area | Lower Surface Area |

| Primary Benefit | Maximum Catalytic Activity | Superior Electronic Transport |

| Purity | Removes Organic Residues | High Crystalline Purity |

Elevate Your Material Research with KINTEK

Precision is the key to mastering the structural evolution of CuO nanoparticles. Whether you are targeting catalytic surface area or electronic crystallinity, KINTEK provides the high-performance thermal solutions you need.

Backed by expert R&D and world-class manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems. Our lab high-temperature furnaces are fully customizable to meet the unique demands of your nanoparticle synthesis protocols.

Ready to optimize your calcination process? Contact KINTEK today to discuss your custom furnace requirements with our technical team!

References

- Muhammad Farooq, Magdi E. A. Zaki. Phytoassisted synthesis of CuO and Ag–CuO nanocomposite, characterization, chemical sensing of ammonia, degradation of methylene blue. DOI: 10.1038/s41598-024-51391-2

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What are the primary uses of muffle furnaces? Essential for Contamination-Free High-Temp Processing

- Why is a high-temperature muffle furnace necessary for LLZO calcination? Master Phase Purity in Solid-State Electrolytes

- What safety measures should be followed when using a muffle furnace? Essential Steps for Safe Operation

- What safety precautions should be taken when using a Muffle furnace? Ensure Lab Safety with Expert Guidelines

- What role does a muffle furnace play in the thermal processing of crystal synthesis? Master Precise Crystal Growth

- How does heat distribution in drying ovens compare to muffle furnaces? Discover Key Differences for Your Lab

- What role does a muffle furnace play in TiO2 sol-gel transformation? Achieve High-Performance Photocatalytic Coatings

- Why is a laboratory muffle furnace used to bake experimental apparatus? Ensure Purity in Shale Oil & Gas Simulations