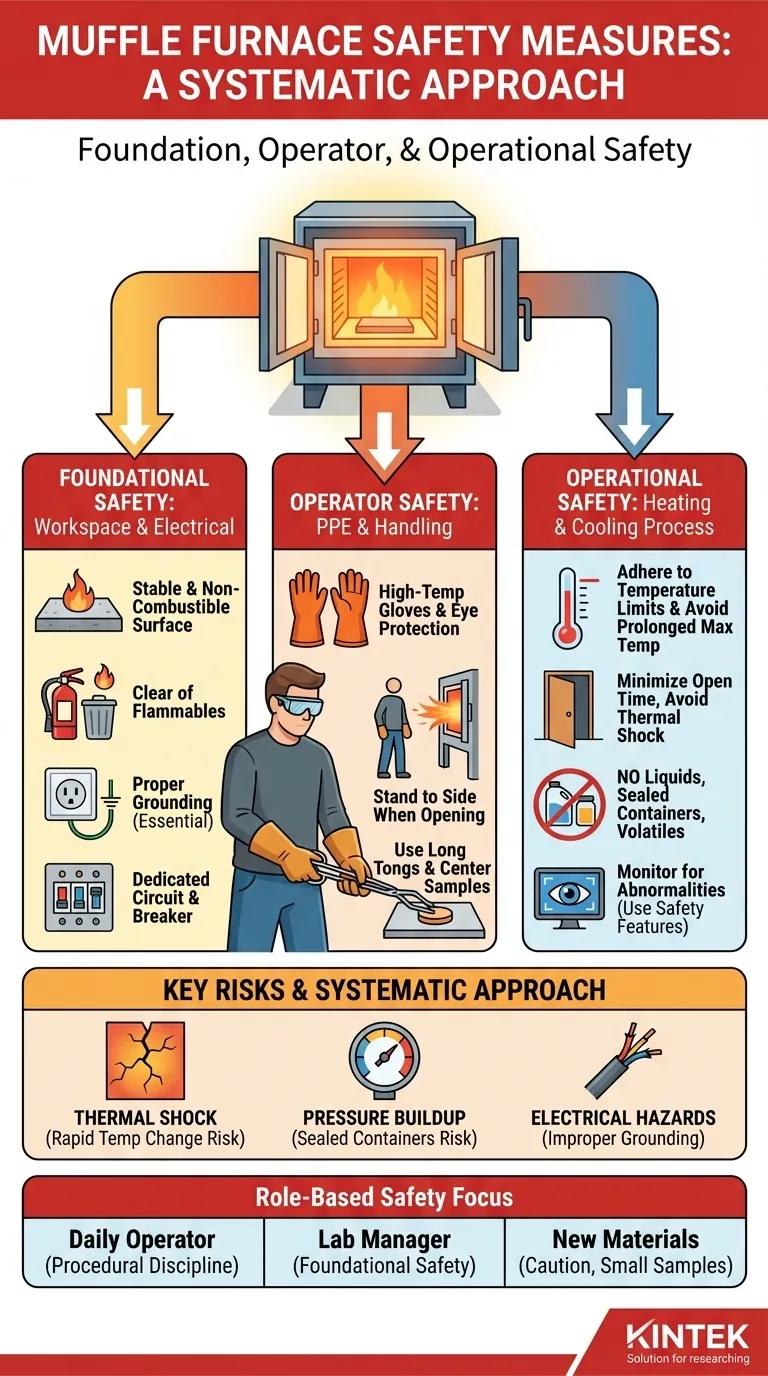

At its core, operating a muffle furnace safely requires a systematic approach encompassing three critical areas: preparing a safe environment, using correct personal protective equipment (PPE), and strictly adhering to operational procedures during heating and cooling. You must ensure the furnace is properly installed and grounded, always wear high-temperature gloves and eye protection, and never exceed the furnace's temperature limits or introduce volatile or prohibited substances.

A muffle furnace is not inherently dangerous, but improper use creates significant risk. True safety is achieved not by a single action, but by understanding the principles of thermal shock, electrical safety, and material volatility, and integrating these principles into every step of your process.

Foundational Safety: The Workspace and Electrical Setup

Before you ever turn the furnace on, you must establish a safe environment. This foundational layer prevents the most catastrophic failures.

Ensuring a Stable and Clear Workspace

The furnace must be placed on a completely stable, level, and non-combustible surface, such as a dedicated cement platform.

The immediate area must be kept clear of all flammable, explosive, or corrosive materials. This is a non-negotiable rule to prevent secondary fires or reactions from the intense heat radiated by the unit.

Critical Electrical Grounding and Power Control

Proper grounding of the furnace is essential to prevent electric shock. Always verify that the unit is connected to a correctly grounded outlet.

The furnace should be connected to a dedicated electrical circuit with an appropriate circuit breaker or fuse. This prevents overloading the building's electrical system and provides a critical safety cutoff.

Operator Safety: Personal Protective Equipment and Handling

With the environment secured, the focus shifts to protecting the operator from the primary hazards: extreme heat and direct contact with hot materials.

Protecting Against Extreme Heat

Always wear high-temperature resistant gloves and safety glasses or a full face shield when loading or unloading the furnace. Standard lab gloves offer no protection from the radiant heat or hot surfaces.

Never stand directly in front of the door when opening it. Stand to the side to avoid the blast of superheated air that will exit the chamber.

Safe Sample Handling Techniques

Use long, sturdy tongs to place and remove samples. Never use your hands, even with gloves, to reach inside the furnace chamber.

Place samples securely in the center of the furnace hearth plate. This ensures even heating and prevents samples from accidentally touching and damaging the heating elements or thermocouple.

Operational Safety: The Heating and Cooling Process

The greatest number of safety procedures apply during the furnace's actual operation. Adherence to these steps is critical for protecting both the operator and the equipment.

Adhering to Temperature Limits

Never program the furnace to exceed its specified maximum operating temperature. Doing so can cause permanent damage to the heating elements and refractory insulation.

Avoid operating the furnace at its maximum rated temperature for extended periods. This shortens the lifespan of critical components.

Managing the Furnace Door

Minimize the time the furnace door is open, especially at high temperatures. This reduces heat loss, protects the operator from heat exposure, and prevents thermal shock to the furnace chamber.

Do not open the door if the internal temperature is above 600°C unless absolutely necessary for the process and with extreme caution. The rapid temperature change can crack the refractory materials.

After a cycle is complete, turn off the power and allow the furnace to cool significantly before fully opening the door to remove samples. Cracking the door slightly can aid in controlled cooling.

Prohibited Materials and Substances

Never place liquids, sealed containers, or highly volatile or oily samples inside the furnace. The rapid heating can cause pressure buildup, leading to a potential explosion and damage to the furnace.

Similarly, do not place any flammable, corrosive, or explosive materials inside the furnace chamber.

Monitoring for Abnormalities

Always monitor the temperature display during operation. If the temperature rises uncontrollably or you notice any other abnormalities, immediately cut power to the unit and investigate the cause once it has cooled.

Modern furnaces often include over-temperature protection and alarms. Ensure these safety features are active and functional.

Understanding the Key Risks

Following procedures is essential, but understanding the "why" behind them empowers you to make safer decisions.

The Danger of Thermal Shock

The refractory ceramic insulation inside a muffle furnace is strong but brittle. Rapid temperature changes—caused by opening the door at high heat or cooling the furnace too quickly—create stress that can cause it to crack and fail. This is known as thermal shock.

The Risk of Pressure Buildup

Heating a substance in a sealed container or heating a sample that releases gases (like moisture or volatile compounds) will increase the pressure inside the furnace chamber. Without a vent, this pressure can force the door open violently or damage the furnace structure.

Electrical Hazards

The risk of electric shock is highest if the furnace is not properly grounded or if wiring becomes frayed. Spilling conductive materials near the furnace can also create a dangerous path for electricity. A dedicated power controller or gate ensures you can cut power decisively in an emergency.

A Systematic Approach to Muffle Furnace Safety

Use these guidelines to tailor your safety protocol to your specific role and objective.

- If you are a daily operator: Your primary focus is procedural discipline—always using the correct PPE, adhering to temperature limits, and following proper sample handling techniques.

- If you are a lab manager: Your primary focus is ensuring the foundational safety of the workspace, providing proper training, and verifying that the furnace's electrical connections and safety features are maintained.

- If you are processing new or unknown materials: Your primary focus is caution—start with very small samples at lower temperatures to understand how the material behaves before committing to a full-scale run.

By treating muffle furnace operation with systematic attention to detail, you transform a powerful tool into a safe and reliable asset.

Summary Table:

| Safety Area | Key Measures |

|---|---|

| Workspace Setup | Stable surface, clear of flammables, proper grounding |

| Personal Protection | High-temperature gloves, safety glasses, cautious door handling |

| Operational Procedures | Adhere to temperature limits, avoid prohibited materials, monitor for abnormalities |

| Risk Understanding | Prevent thermal shock, pressure buildup, and electrical hazards |

Ensure your laboratory's safety and efficiency with KINTEK's advanced high-temperature furnace solutions. Leveraging exceptional R&D and in-house manufacturing, we provide Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all with strong deep customization to meet your unique experimental needs. Contact us today for expert guidance and reliable equipment tailored to your requirements!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What metals cannot be heated by induction? Understanding Material Suitability for Efficient Heating

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation

- What is the role of a muffle furnace in the study of biochar regeneration and reuse? Unlock Sustainable Water Treatment

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis