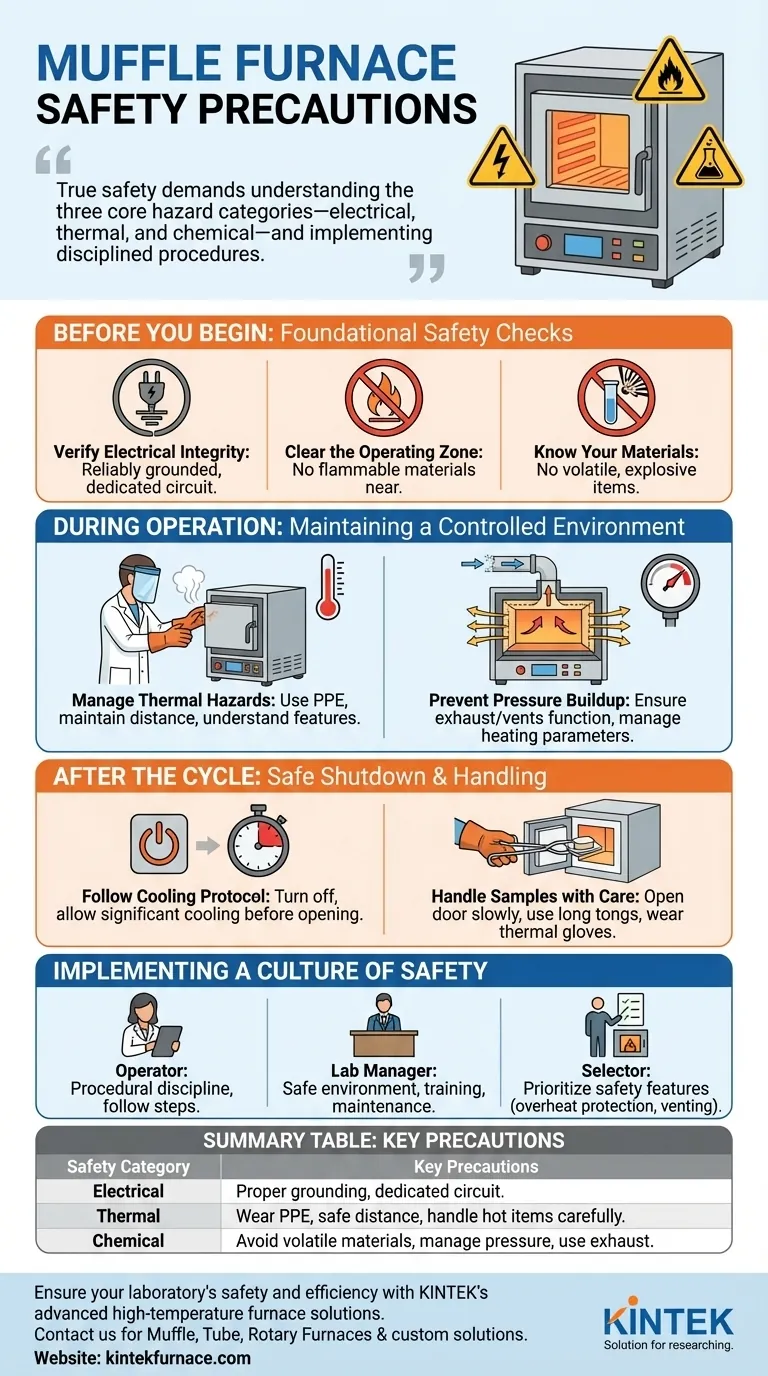

Operating a muffle furnace requires strict adherence to safety protocols to mitigate significant risks. The primary precautions involve ensuring proper electrical grounding, maintaining a clear zone free of flammable materials, preventing burns from extreme temperatures, and managing potential pressure buildup from volatile samples during the heating process.

True muffle furnace safety extends beyond a simple checklist. It demands a fundamental understanding of the three core hazard categories—electrical, thermal, and chemical—and implementing disciplined procedures before, during, and after every operation.

Before You Begin: Foundational Safety Checks

Before powering on the furnace, you must establish a safe operating environment. These initial checks are your first and most critical line of defense against common accidents.

Verify Electrical Integrity

The furnace must be reliably grounded to prevent the risk of electric shock. This is non-negotiable.

Connect the furnace to a dedicated power circuit with its own control switch. This prevents overloading and allows you to cut all power quickly in an emergency.

Clear the Operating Zone

Ensure no flammable or explosive materials are stored anywhere near the furnace. The high external temperatures can create a significant fire hazard even without direct contact.

Know Your Materials

Never place explosive, volatile, or dangerous materials inside the furnace chamber. Heating such items can lead to rapid gas expansion, pressure buildup, and potentially catastrophic failure of the unit.

During Operation: Maintaining a Controlled Environment

Constant vigilance is required while the furnace is active. The primary goals are to manage thermal hazards and ensure the stability of the internal atmosphere.

Manage Thermal Hazards

Even with modern insulation, the exterior surfaces of a muffle furnace can become extremely hot. Maintain a safe distance and never touch the unit without appropriate Personal Protective Equipment (PPE), such as heat-resistant gloves.

The furnace's design often includes features like insulated doors and adjustable air inlets to protect you from hot surfaces and aggressive gases. Understand how these features work on your specific model.

Prevent Pressure Buildup

Sudden changes in heating parameters can cause some materials to release gases rapidly, leading to dangerous pressure buildup inside the sealed chamber.

If your furnace has an exhaust system or vent, ensure it is functioning correctly to safely route gases away from the work area and prevent pressure-related accidents.

Understanding the Trade-offs: Built-in vs. Procedural Safety

Modern furnaces come with engineered safety controls, but these do not eliminate the need for operator diligence. Understanding the relationship between the two is key to a safe lab environment.

The Role of Engineered Controls

Features like overheat protection, sealed muffle chambers, and advanced insulation are designed to make operation safer and more predictable. They reduce the risk of equipment failure and protect samples from contamination.

These systems provide a crucial safety buffer, but they are not foolproof. They are intended to assist, not replace, a trained and attentive operator.

The Limits of Automation

Never assume that automated safety mechanisms will prevent every possible accident. A sensor can fail, or a situation can develop that falls outside the system's design parameters.

Procedural discipline—following the correct steps every single time—remains the most important safety factor. Your knowledge and actions are the ultimate safety control.

After the Cycle: Safe Shutdown and Handling

The risk of injury does not end when the heating cycle is complete. The furnace and its contents remain dangerously hot for a significant period.

Follow a Cooling Protocol

After the experiment is finished, turn off the main power supply. Allow the furnace to cool down considerably before attempting to open the door.

Handle Samples with Care

When removing samples, open the door slightly at first to allow heat to dissipate gradually. Use long tongs and wear thermal gloves to carefully remove the items, preventing severe burns.

Implementing a Culture of Safety

To ensure long-term safety, integrate these principles into your lab's standard operating procedures. The right focus depends on your role.

- If you are an operator: Your primary responsibility is procedural discipline—always follow the correct steps for startup, operation, and shutdown.

- If you are a lab manager: Your focus should be on ensuring the environment is safe, the equipment is properly installed and maintained, and all users are thoroughly trained.

- If you are selecting a new furnace: Prioritize models with robust safety features like certified overheat protection, integrated venting, and superior insulation.

Ultimately, safety is a continuous process of awareness and discipline, not a one-time checklist.

Summary Table:

| Safety Category | Key Precautions |

|---|---|

| Electrical | Ensure proper grounding, use dedicated power circuit |

| Thermal | Wear PPE, maintain safe distance, handle hot items with care |

| Chemical | Avoid volatile materials, manage pressure buildup, use exhaust systems |

Ensure your laboratory's safety and efficiency with KINTEK's advanced high-temperature furnace solutions. Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with reliable products like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability precisely meets your unique experimental needs. Contact us today to discuss how we can enhance your operations and deliver tailored solutions for your safety challenges!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production

- What is the role of a muffle furnace in the study of biochar regeneration and reuse? Unlock Sustainable Water Treatment