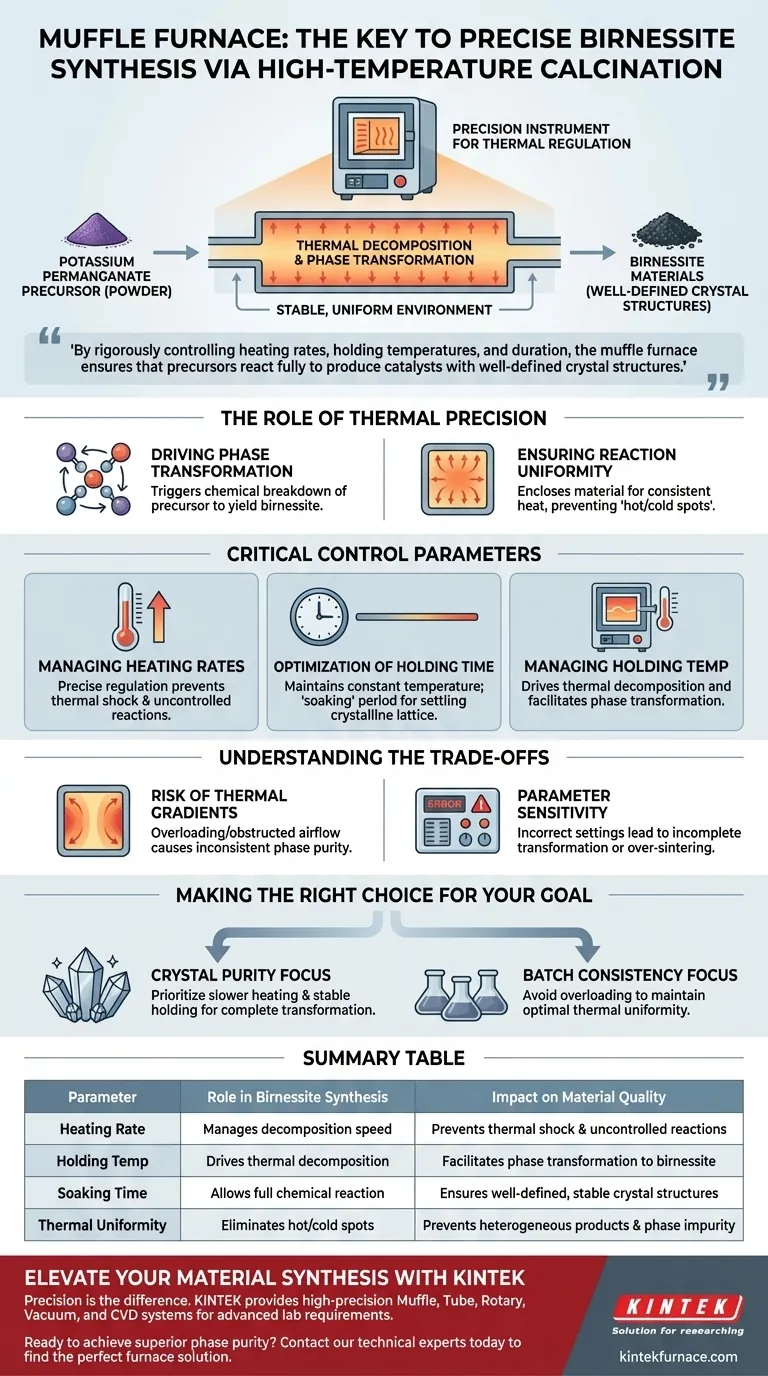

In the preparation of birnessite materials, the muffle furnace serves as a precision instrument for thermal regulation. Its primary function is to provide a stable, uniform environment that facilitates the thermal decomposition of potassium permanganate powder, driving the necessary phase transformation to create the final material.

By rigorously controlling heating rates, holding temperatures, and duration, the muffle furnace ensures that precursors react fully to produce catalysts with well-defined crystal structures.

The Role of Thermal Precision

Driving Phase Transformation

The synthesis of birnessite is not merely about heating a substance; it is about managing a chemical change.

The muffle furnace creates the specific conditions required for thermal decomposition. Under these conditions, the potassium permanganate precursor breaks down chemically. This decomposition is the trigger for the phase transformation that ultimately yields the birnessite structure.

Ensuring Reaction Uniformity

A critical challenge in high-temperature calcination is ensuring that the entire batch of material experiences the exact same conditions.

The muffle furnace addresses this by providing a stable thermal environment. Unlike open flames or uneven heating sources, a muffle furnace encloses the material to ensure consistent heat distribution. This prevents "hot spots" or "cold spots" that could lead to heterogeneous products.

Critical Control Parameters

Managing Heating Rates

The speed at which temperature increases is just as important as the final temperature reached.

The muffle furnace allows for the precise regulation of the heating rate. This control ensures that the decomposition happens gradually and predictably, preventing thermal shock or rapid, uncontrolled reactions that could degrade the material's quality.

Optimization of Holding Time

Achieving the correct crystal structure requires a specific duration of heat exposure.

By maintaining a constant holding temperature for a set duration, the furnace allows the precursors to react fully. This "soaking" period is vital for settling the crystalline lattice into the desired well-defined structure.

Understanding the Trade-offs

The Risk of Thermal Gradients

While muffle furnaces are designed for uniformity, they are not immune to operator error or overloading.

If the furnace is packed too tightly or air circulation is obstructed, thermal gradients can occur. This results in the outer layers of the powder calcining faster than the core, leading to inconsistent phase purity across the batch.

Parameter Sensitivity

The precision of a muffle furnace is only as good as the parameters set by the user.

An incorrect heating rate or insufficient holding time can result in incomplete phase transformation. Conversely, excessive temperatures or duration may lead to over-sintering, where particles fuse excessively, potentially reducing the active surface area of the catalyst.

Making the Right Choice for Your Goal

To maximize the quality of your birnessite materials, align your furnace settings with your specific objectives.

- If your primary focus is Crystal Purity: Prioritize a slower heating rate and a stable holding temperature to ensure complete and uniform phase transformation.

- If your primary focus is Batch Consistency: Ensure the furnace is not overloaded to maintain optimal thermal uniformity throughout the chamber.

The muffle furnace is the gatekeeper of your material's structural integrity; precise control here dictates the performance of the final catalyst.

Summary Table:

| Parameter | Role in Birnessite Synthesis | Impact on Material Quality |

|---|---|---|

| Heating Rate | Manages decomposition speed | Prevents thermal shock & uncontrolled reactions |

| Holding Temp | Drives thermal decomposition | Facilitates phase transformation to birnessite |

| Soaking Time | Allows full chemical reaction | Ensures well-defined, stable crystal structures |

| Thermal Uniformity | Eliminates hot/cold spots | Prevents heterogeneous products & phase impurity |

Elevate Your Material Synthesis with KINTEK

Precision is the difference between a failed reaction and a high-performance catalyst. Backed by expert R&D and world-class manufacturing, KINTEK provides high-precision Muffle, Tube, Rotary, Vacuum, and CVD systems tailored for advanced lab requirements. Whether you are synthesizing birnessite or developing next-gen catalysts, our customizable high-temperature furnaces ensure the thermal stability and uniformity your research demands.

Ready to achieve superior phase purity? Contact our technical experts today to find the perfect furnace solution for your laboratory.

Visual Guide

References

- Wei Jia, Mengnan Yu. Study on the activity of doped metal-modified water-sodium- manganese ore catalyst to catalyze the degradation of dimethylamine. DOI: 10.21203/rs.3.rs-7291479/v1

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- How is a laboratory high-temperature muffle furnace utilized to achieve the specific crystalline structure of LaFeO3 catalysts?

- Why is a precise muffle furnace required for Pt/Al2O3 catalyst calcination? Ensure High Activity and Dispersion

- What industrial applications do muffle furnaces have in heat treating? Precision Solutions for High-Tech Industries

- What are the installation and maintenance benefits of electric furnaces? Achieve Simpler, Lower-Cost Heating

- Why was the muffle furnace initially developed? To Ensure Purity in High-Temperature Processing

- How does a laboratory box furnace contribute to the temperature program control for synthesizing PrVSb3 single crystals?

- What role does a muffle furnace play in the preparation of ER-SnmCunOx-t/CC electrocatalysts? Achieve Optimal Purity

- What are the final considerations when choosing a muffle furnace? Ensure Long-Term Value and Safety