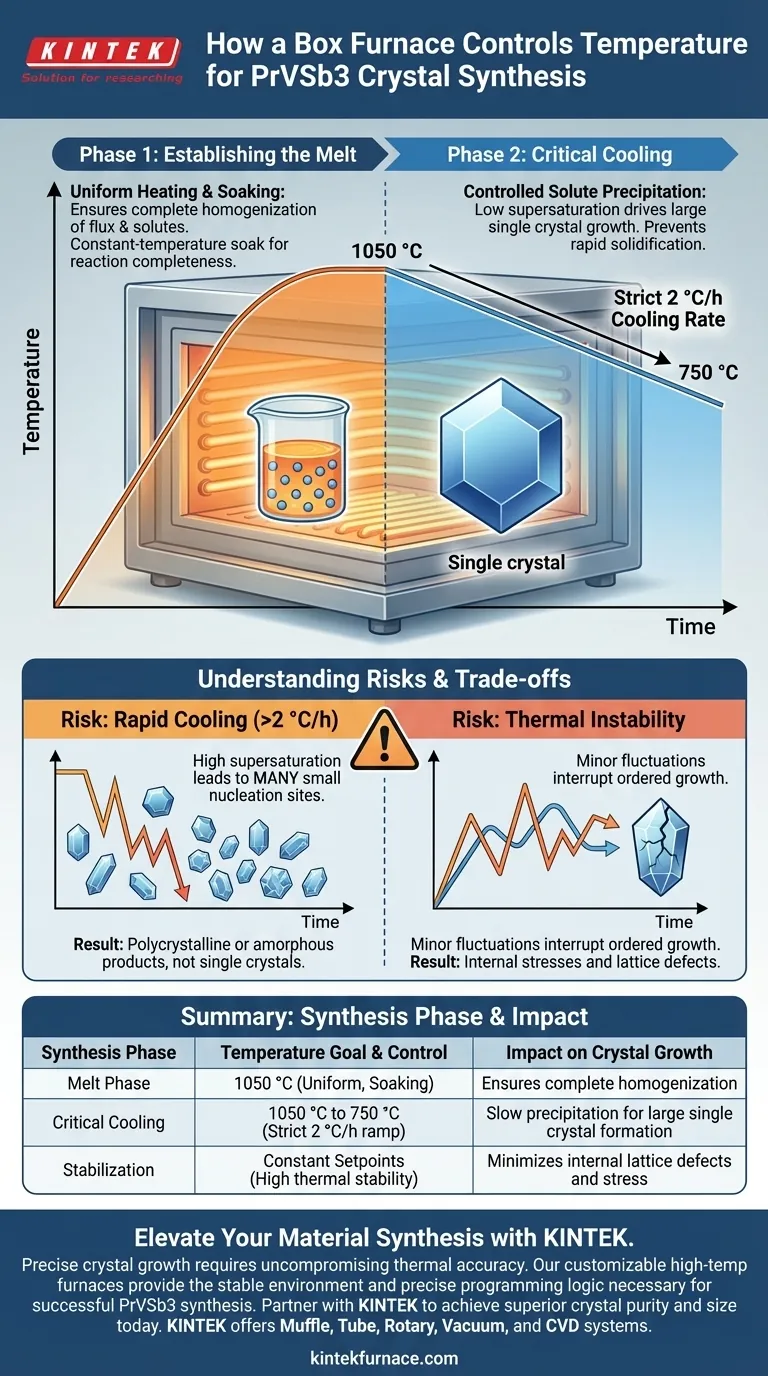

Precise thermal management is the primary contribution of a laboratory box furnace to PrVSb3 synthesis, specifically through the execution of complex, multi-stage temperature profiles. By maintaining a highly stable environment, the furnace enables a controlled ramp-up to 1050 °C for uniform melting, followed by a critical slow-cooling phase that drives crystal formation.

Core Takeaway: The box furnace acts as a programmable environment that dictates the rate of solute precipitation. For PrVSb3, its ability to execute a precise cooling rate of 2 °C/h (from 1050 °C to 750 °C) is the deciding factor in growing large, high-quality single crystals rather than polycrystalline structures.

Establishing the Melt Phase

To synthesize PrVSb3 single crystals, the initial heating phase is as critical as the cooling phase. The box furnace ensures the raw materials reach a homogenized state before growth begins.

Uniform Melting at High Temperatures

The furnace facilitates a slow ramp-up to a target temperature of 1050 °C. Reaching this specific threshold is necessary to ensure the flux and solutes are completely melted and uniformly mixed.

Ensuring Reaction Completeness

While the target is 1050 °C, the stability provided by the box furnace allows for a "soaking" period. This constant-temperature phase ensures that all raw materials have fully reacted and diffused within the melt before any cooling begins.

The Critical Cooling Phase

The most distinct contribution of the box furnace is its ability to control the cooling trajectory. This is where the actual crystal growth occurs.

Controlling Solute Precipitation

The furnace is programmed to cool the melt from 1050 °C down to 750 °C at a strictly controlled rate of 2 °C/h. This slow rate is vital because it governs how fast the PrVSb3 solute precipitates from the flux.

Driving Single Crystal Growth

By limiting the cooling rate to 2 °C/h, the furnace maintains a low level of supersaturation. This prevents rapid solidification, allowing the precipitating solute to deposit continuously onto nuclei to form large-sized single crystals.

Understanding the Trade-offs

While laboratory box furnaces are essential for this process, understanding the variables involved in thermal programming is critical to avoiding failure.

The Risk of Rapid Cooling

If the furnace cannot maintain the strict 2 °C/h rate and cools too quickly, the supersaturation level will rise too high. This typically results in the formation of many small nucleation sites, leading to polycrystalline or amorphous products rather than a single, large crystal.

Thermal Stability vs. Stress

A furnace that lacks thermal stability can introduce temperature fluctuations during the cooling ramp. Even minor deviations can interrupt the ordered growth process, potentially introducing internal stresses or defects into the crystal lattice.

Making the Right Choice for Your Goal

To maximize the quality of your PrVSb3 crystals, you must align your equipment capabilities with your specific synthesis targets.

- If your primary focus is Crystal Size: Prioritize a furnace with exceptional insulation and programming logic that guarantees the cooling rate never exceeds 2 °C/h, as this duration dictates the growth volume.

- If your primary focus is Crystal Purity: Ensure the furnace can hold the peak temperature (1050 °C) with minimal fluctuation to guarantee complete homogenization of the melt prior to cooling.

Summary: The success of PrVSb3 synthesis relies entirely on the box furnace’s ability to mechanically enforce a slow, linear reduction in temperature to choreograph the precipitation of the crystal from the flux.

Summary Table:

| Synthesis Phase | Temperature Goal | Control Requirement | Impact on Crystal Growth |

|---|---|---|---|

| Melt Phase | 1050 °C | Uniform heating & soaking | Ensures complete homogenization of solutes |

| Critical Cooling | 1050 °C to 750 °C | Strict 2 °C/h ramp | Slow precipitation for large single crystal formation |

| Stabilization | Constant Setpoints | High thermal stability | Minimizes internal lattice defects and stress |

Elevate Your Material Synthesis with KINTEK

Precise crystal growth requires uncompromising thermal accuracy. Backed by expert R&D and world-class manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems tailored for the most demanding laboratory applications.

Our customizable high-temp furnaces provide the stable environment and precise programming logic necessary for successful PrVSb3 synthesis and beyond. Partner with KINTEK to achieve superior crystal purity and size today.

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- Why is temperature control important in a muffle furnace? Ensure Accurate, Repeatable Results

- Why is the thermal sintering process in a muffle furnace necessary for post-processing aluminum matrix composites?

- How does a laboratory muffle furnace facilitate the pyrolysis of Plum Stone Biochar? Optimize Your Carbon Production

- What is the role of a laboratory muffle furnace in the oxidative annealing of black indium oxide particles?

- What role does a laboratory oven play in lignin nanofiber stabilization? Unlock Precision Thermal Cross-linking

- Why is a muffle furnace required for sodium-ion cathode heat treatment? Engineering P2/P3 Crystal Phase Structures

- What is the role of Muffle or Tube furnaces in carbon nitride preparation? Optimize Your Thermal Polymerization

- What are the standard specifications for Box Furnaces? Key Components for Precision and Efficiency