At its core, a standard box furnace is defined by a specific set of components designed for reliability and process control. These specifications typically include electric heaters arranged for uniform temperature, SCR power control, a NEMA 12-rated control panel for industrial environments, a multi-function timer, an emergency stop button, and high-density, energy-saving insulation.

The list of specifications is not just a checklist; it's a blueprint for achieving three critical outcomes: precise temperature uniformity, repeatable process control, and long-term operational efficiency. Understanding how these components serve these goals is key to evaluating any box furnace.

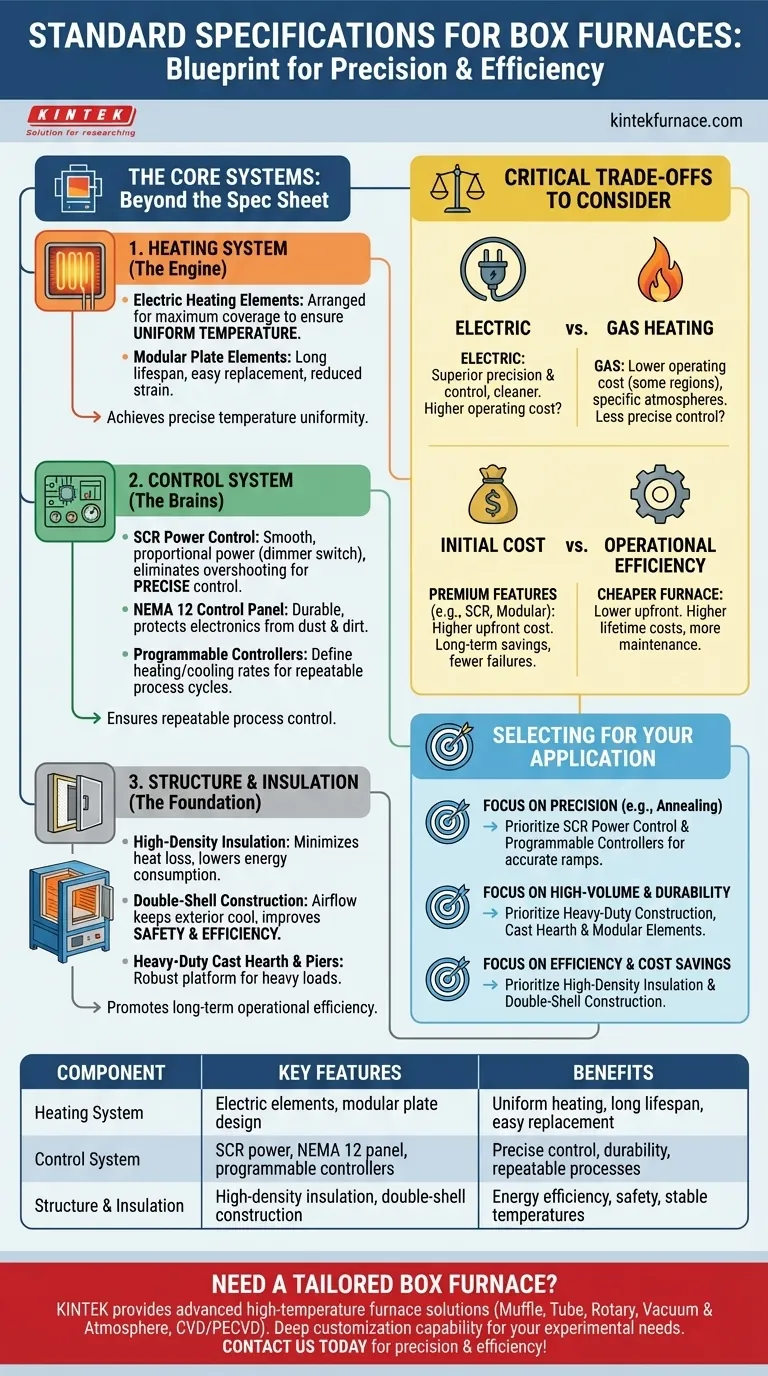

The Core Systems: Beyond the Spec Sheet

A box furnace is an integrated system. To understand its specifications, you must understand how its three primary systems work together to deliver consistent, reliable thermal processing for applications like annealing, curing, and stress relief.

The Heating System: The Engine of the Furnace

The quality of the heating system directly dictates the furnace's performance and lifespan.

It starts with electric heating elements configured for maximum coverage within the chamber. This arrangement is the first step toward achieving temperature uniformity, preventing hot or cold spots that could ruin a process.

Many high-quality furnaces use modular plate heating elements. These are known for their longevity and ease of replacement. This design often allows the furnace to operate without the typical watt-density limitations, reducing strain on the elements and extending their service life.

The Control System: The Brains of the Operation

The control system dictates how the furnace applies heat, which is critical for sensitive processes.

SCR (Silicon-Controlled Rectifier) control is a non-negotiable standard for precision. Unlike simple on/off mechanical contactors, SCRs act like a dimmer switch, providing smooth and proportional power to the heating elements. This eliminates temperature overshooting and provides highly uniform temperature control.

A NEMA 12 Control Panel is an industry standard that signifies durability. This enclosure protects sensitive electronics from dust, dirt, and dripping non-corrosive liquids, ensuring reliability in a typical industrial setting.

Finally, fully programmable controllers allow operators to define precise heating and cooling rates. For processes like annealing, the ability to control the entire thermal cycle is essential for achieving the desired material properties.

The Structure & Insulation: The Foundation of Efficiency

The physical construction of the furnace is central to its efficiency, safety, and durability.

High-density, energy-saving insulation is used to minimize heat loss. This directly translates to lower energy consumption and a more stable internal temperature.

Look for double-shell construction. This design allows for airflow between the inner and outer furnace walls, keeping the exterior surface cool to the touch. This improves safety and further reduces energy waste into the surrounding workspace.

The furnace's physical structure, including a heavy-duty cast hearth and piers, provides the robust platform needed to support heavy loads for years without deformation. Door mechanisms, such as vertical lift or swing-out designs, are chosen based on workflow and floor space requirements.

Critical Trade-offs to Consider

Choosing a box furnace involves balancing competing priorities. Understanding these trade-offs is essential for making an informed decision that aligns with your operational goals.

Electric vs. Gas Heating

While electric heating is most common for precision, gas is an option. Electric furnaces offer superior temperature uniformity and control, are cleaner, and are often simpler to install. Gas-fired furnaces can offer a lower operating cost in regions with high electricity prices and may be necessary for specific atmospheres, but they can be more complex to control with the same level of precision.

Initial Cost vs. Operational Efficiency

A furnace with premium components like modular heating elements, dense insulation, and SCR controls will have a higher upfront cost. However, these features deliver significant long-term savings through lower energy bills, reduced maintenance, and fewer failed process cycles. A cheaper furnace often costs more over its lifetime.

Selecting a Furnace for Your Application

Your specific application should dictate which specifications you prioritize.

- If your primary focus is process precision (e.g., annealing, stress relief): Ensure the furnace has SCR power control and a fully programmable controller to manage heating and cooling ramps accurately.

- If your primary focus is high-volume production and durability: Prioritize heavy-duty construction, a robust cast hearth, and modular heating elements known for their long service life.

- If your primary focus is operational efficiency and cost savings: Look for specifications that detail the type and thickness of the high-density insulation and confirm the furnace has double-shell construction.

Ultimately, a well-specified box furnace is a tool engineered for consistency, and your goal is to match its capabilities to your process needs.

Summary Table:

| Specification Component | Key Features | Benefits |

|---|---|---|

| Heating System | Electric elements, modular plate design | Uniform heating, long lifespan, easy replacement |

| Control System | SCR power, NEMA 12 panel, programmable controllers | Precise temperature control, durability, repeatable processes |

| Structure & Insulation | High-density insulation, double-shell construction | Energy efficiency, safety, stable temperatures |

| Trade-offs | Electric vs. gas heating, cost vs. efficiency | Balance precision, operating costs, and long-term savings |

Need a box furnace tailored to your lab's unique needs? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your experimental requirements for applications like annealing, curing, and stress relief. Contact us today to enhance your process precision and efficiency!

Visual Guide

Related Products

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What is a quartz tube furnace and what is its primary use? Essential for Controlled High-Temp Processing

- What happens to convective and radiative heat transfer effects at high furnace gas temperatures? Radiation Dominates for Superior Heating

- What factors should be considered when purchasing a quartz tube furnace? Ensure Reliable High-Temperature Processing

- What is a Quartz Tube Furnace and what is its primary function? Essential for Real-Time Material Observation

- What is the difference between an alumina tube furnace and a quartz tube furnace? Choose the Right Tube Furnace for Your Lab