At its core, temperature control is the single most critical factor for achieving accurate, repeatable, and valid results from a muffle furnace. Without precise regulation, the furnace becomes an unreliable tool, rendering experiments inconsistent and potentially damaging the materials you are processing. It ensures that the specific chemical and physical changes you intend to happen, do happen—exactly as planned.

The importance of temperature control extends beyond simply reaching a set temperature. True control is about managing the entire thermal profile—including the rate of heating, the duration of holds, and the rate of cooling—as this entire process dictates the final properties of your material and the integrity of your results.

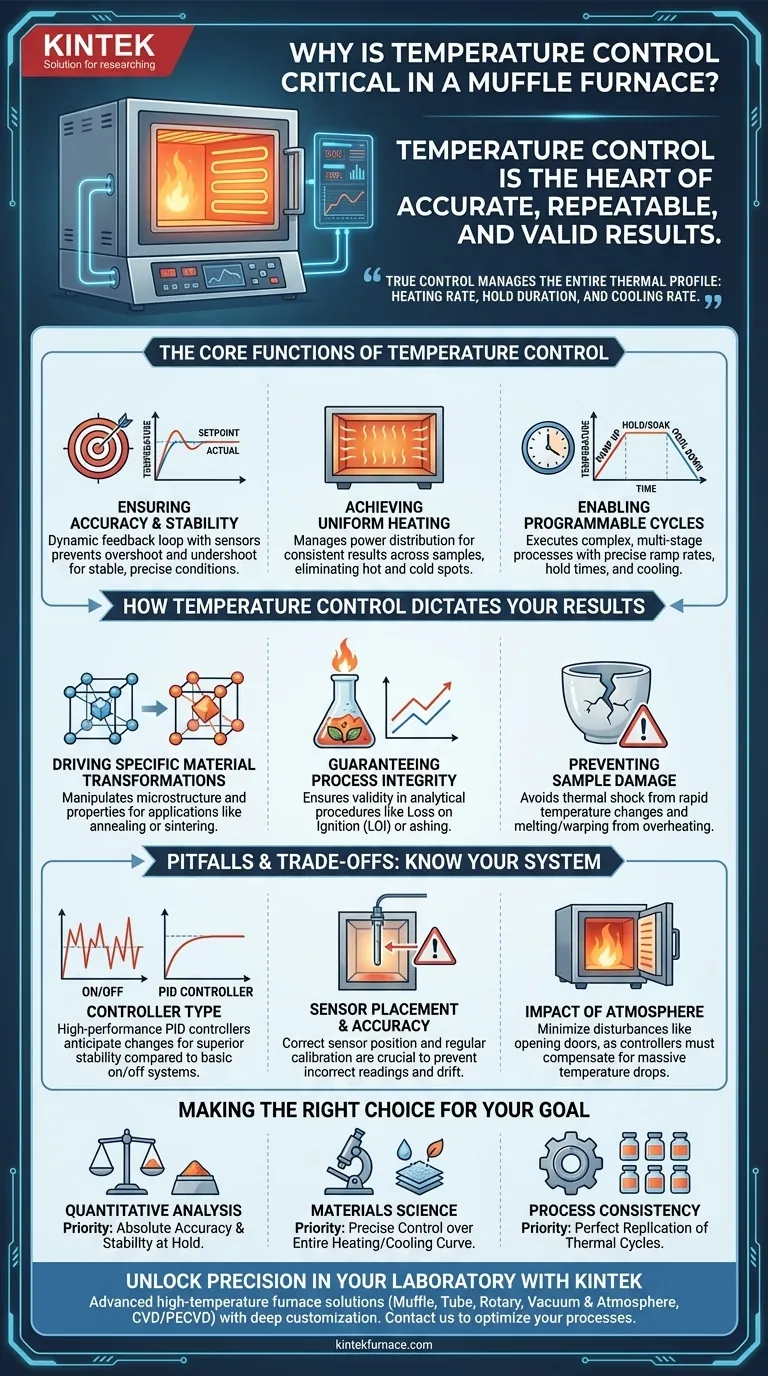

The Core Functions of Temperature Control

To understand why temperature control is paramount, we must first look at what a modern control system actually does. It's not just a simple thermostat; it's a dynamic feedback system designed for precision.

Ensuring Accuracy and Stability

A temperature controller works in a continuous loop with a sensor (like a thermocouple) inside the chamber. The sensor reports the current temperature to the controller, which then adjusts the power sent to the heating elements to maintain the desired setpoint.

This constant adjustment prevents temperature overshoot (going past the target) and undershoot (dropping below it), ensuring the process remains stable and accurate.

Achieving Uniform Heating

Precise control allows the system to manage power distribution effectively, ensuring the entire chamber heats uniformly. This eliminates hot and cold spots, which can lead to inconsistent results across a single sample or between different samples in the same batch.

Uniformity is vital for processes where the entire material must undergo the same transformation simultaneously.

Enabling Programmable Cycles

Modern furnaces allow you to program complex thermal cycles. This includes:

- Ramp Rate: The speed at which the temperature increases.

- Hold Time (Soak): The duration the furnace stays at a specific temperature.

- Cooling Rate: The speed at which the temperature decreases.

This programmability allows you to execute highly specific, multi-stage processes required for advanced materials synthesis and testing.

How Temperature Control Dictates Your Results

The functions of a control system directly translate to the success or failure of your work. The final properties of a material are often a direct consequence of its thermal history.

Driving Specific Material Transformations

For materials scientists, the thermal cycle is a tool to manipulate a material's fundamental properties. Precise temperature control allows for the intentional modification of crystal structure, microstructure, and composition.

Whether you are annealing metal to increase ductility or sintering ceramic powders, the specific ramp rates and hold times determine the final outcome.

Guaranteeing Process Integrity

In many applications, the temperature itself is the independent variable being tested. In analytical procedures like Loss on Ignition (LOI) or ashing, the goal is to burn off organic matter at a specific temperature to measure the remaining inorganic content.

If the temperature is inaccurate or unstable, the results of the analysis become invalid. For processes like firing ceramics, incorrect temperatures can mean the difference between proper fusion and a cracked, failed part.

Preventing Sample Damage

Too rapid a heating or cooling rate can induce thermal shock, causing brittle materials like ceramics or glass to crack and break.

Likewise, holding a material at a temperature even slightly above its intended processing point can cause it to melt, warp, or undergo an undesirable chemical change, ruining the sample entirely.

Understanding the Pitfalls and Trade-offs

While essential, not all temperature control systems are created equal. Understanding their limitations is key to ensuring your process is reliable.

Controller Type vs. Precision

Simpler furnaces may use a basic on/off controller, which can lead to significant temperature fluctuations around the setpoint.

High-performance furnaces use PID (Proportional-Integral-Derivative) controllers. These advanced systems anticipate temperature changes and make smoother, more precise power adjustments, resulting in far greater stability.

Sensor Placement and Accuracy

A control system is only as good as the information it receives. The temperature sensor must be placed correctly to read the actual temperature your sample is experiencing.

Furthermore, sensors can drift over time and require periodic calibration. An uncalibrated sensor will report an incorrect temperature, causing the controller to unknowingly maintain the wrong conditions in the chamber.

The Impact of Atmosphere

Opening the furnace door causes a massive and immediate temperature drop. Even adjusting the air intake or exhaust vents introduces a variable that the control system must compensate for.

A robust controller can recover from these disturbances quickly, but it's critical to minimize them during sensitive phases of a thermal cycle.

Making the Right Choice for Your Goal

Your specific application determines which aspect of temperature control is most critical.

- If your primary focus is quantitative analysis (like Ashing or LOI): Your priority is absolute accuracy and stability at the hold temperature to ensure complete and repeatable reactions.

- If your primary focus is materials science (like sintering or annealing): Your priority is precise control over the entire heating and cooling curve, as this entire profile defines the final microstructure and properties of your material.

- If your primary focus is process consistency for quality control: Your priority is the ability to program and perfectly replicate the exact same thermal cycle for every batch to ensure uniform product quality.

Ultimately, mastering temperature control is how you transform a muffle furnace from a simple oven into a precise scientific instrument.

Summary Table:

| Aspect | Key Points |

|---|---|

| Accuracy & Stability | Prevents overshoot/undershoot, ensures stable temperature for reliable processes. |

| Uniform Heating | Eliminates hot/cold spots for consistent results across samples. |

| Programmable Cycles | Enables control of ramp rates, hold times, and cooling for specific thermal profiles. |

| Impact on Results | Drives material transformations, ensures process integrity, and prevents sample damage. |

| Common Pitfalls | Includes controller type limitations, sensor calibration needs, and atmosphere effects. |

Unlock Precision in Your Laboratory with KINTEK

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Whether you need accurate temperature control for materials science, quantitative analysis, or quality control, we deliver reliable, tailored solutions to enhance your results. Contact us today to discuss how our furnaces can optimize your processes and drive success!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the purpose of heating a precursor solution to 80 °C and 300 rpm stirring? Achieve High-Entropy Uniformity

- How does the use of a 100-mesh sieve contribute to the performance consistency of magnetic chitosan carbon?

- Why is re-calcination in a muffle furnace necessary for photocatalysts? Restore Efficiency via Thermal Oxidation

- What is the primary function of a high-temperature box resistance furnace? Optimize Superalloy Homogenization

- What is the core role of a muffle furnace in the synthesis of calcium oxide from eggshells? Achieve High-Purity CaO