A precise muffle furnace is strictly required for the calcination of Pt/Al2O3 catalysts to ensure the uniform activation of the platinum precursor without destroying its structure. Without exact temperature regulation, typically around 500 °C, you risk the abnormal growth of platinum grains, which drastically reduces the catalyst's dispersion and overall performance.

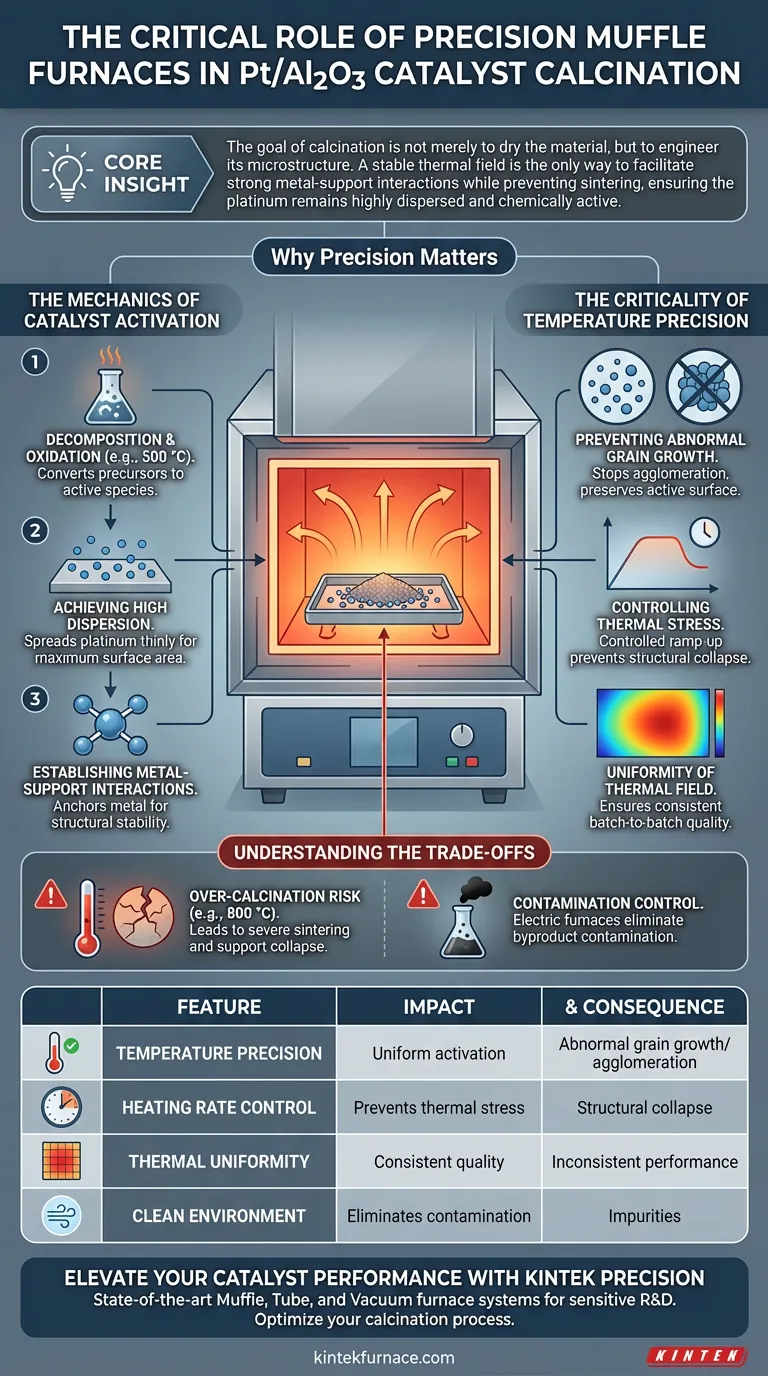

Core Insight: The goal of calcination is not merely to dry the material, but to engineer its microstructure. A stable thermal field is the only way to facilitate strong metal-support interactions while preventing sintering, ensuring the platinum remains highly dispersed and chemically active.

The Mechanics of Catalyst Activation

Decomposition of the Precursor

The primary function of the furnace is to provide a high-temperature oxidizing environment (often 500 °C). This heat triggers the chemical decomposition and oxidation of the platinum precursor loaded onto the alumina support.

This process converts the raw salts into the active species required for catalysis. Without reaching this specific thermal threshold, the precursor remains inactive and the catalyst will fail to function.

Achieving High Dispersion

For a Pt/Al2O3 catalyst to be effective, the platinum must be spread thinly across the support rather than clumped together.

The muffle furnace facilitates this by allowing the platinum species to bond with the alumina surface. This results in highly dispersed active species, maximizing the surface area available for chemical reactions.

Establishing Metal-Support Interactions

A stable temperature field ensures the formation of appropriate interactions between the active platinum components and the alumina support.

These interactions are the "anchor" that holds the metal in place. They are critical for the structural stability of the catalyst, preventing the metal from leaching out during subsequent use.

The Criticality of Temperature Precision

Preventing Abnormal Grain Growth

The most significant risk during calcination is temperature fluctuation. If the temperature spikes or is inconsistent, it causes abnormal growth of platinum grains.

When grains grow too large (agglomeration), the active surface area drops precipitously. Precision control locks the temperature at the exact point where activation occurs without triggering this unwanted growth.

Controlling Thermal Stress

Modern muffle furnaces allow for programmable heating rates (e.g., 2 °C/min). This controlled ramp-up is vital to prevent thermal stress.

Rapid heating can shock the material, causing particles to undergo excessive sintering or structural collapse. A slow, controlled rise allows the material to stabilize gradually, preserving pore structure.

Uniformity of the Thermal Field

Advanced muffle furnaces utilize electric heating elements to create a perfectly uniform thermal field across the chamber.

This ensures that every batch of catalyst receives the exact same thermal treatment. This repeatability is essential for industrial applications where inconsistent catalyst performance can lead to process failure.

Understanding the Trade-offs

The Risk of Over-Calcination

While heat is necessary, excessive temperatures are destructive. If the furnace overshoots—for example, reaching 800 °C instead of the target 500 °C—it can lead to severe sintering.

At these high temperatures, the pore structure of the alumina support may collapse. This reduces the concentration of surface oxygen vacancies and effectively ruins the material's crystallinity and surface activity.

Contamination Control

Traditional combustion-based heating methods introduce byproducts that can contaminate sensitive catalysts.

Modern electric muffle furnaces eliminate this risk. They provide a contamination-free environment, ensuring that the chemical composition of the Pt/Al2O3 remains pure and unaltered by external exhaust gases.

Making the Right Choice for Your Goal

To maximize the performance of your Pt/Al2O3 catalysts, apply the following principles when configuring your thermal treatment:

- If your primary focus is Maximizing Activity: Prioritize a furnace with tight fluctuation control to maintain high platinum dispersion and prevent grain growth.

- If your primary focus is Structural Stability: Ensure your program uses a slow, controlled heating rate to establish strong metal-support interactions without thermal shock.

Precision in calcination is the difference between a high-performance catalyst and expensive inert dust.

Summary Table:

| Feature | Impact on Pt/Al2O3 Catalyst | Consequence of Poor Control |

|---|---|---|

| Temperature Precision | Ensures uniform platinum activation | Abnormal grain growth/agglomeration |

| Heating Rate Control | Prevents thermal stress & sintering | Structural collapse of alumina support |

| Thermal Uniformity | Consistent batch-to-batch quality | Inconsistent catalytic performance |

| Clean Environment | Eliminates chemical contamination | Impurities in sensitive catalysts |

Elevate Your Catalyst Performance with KINTEK Precision

Don't let temperature fluctuations turn your expensive platinum into inert dust. KINTEK provides state-of-the-art Muffle, Tube, and Vacuum furnace systems specifically designed for sensitive R&D and industrial applications.

Our equipment offers the stable thermal fields and programmable heating rates necessary to achieve superior metal dispersion and structural stability for your Pt/Al2O3 catalysts. Backed by expert R&D and manufacturing, KINTEK high-temperature furnaces are fully customizable to meet your unique lab requirements.

Ready to optimize your calcination process? Contact our experts today to find the perfect thermal solution for your materials.

Visual Guide

References

- Lu Dong, Xinggui Zhou. Structure Robustness of Highly Dispersed Pt/Al2O3 Catalyst for Propane Dehydrogenation during Oxychlorination Regeneration Process. DOI: 10.3390/catal14010048

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- How does the position of gas inlets in a muffle furnace affect the temperature distribution? Master Thermal Uniformity

- What role does an industrial-grade ashing furnace play in the synthesis of activated carbon? Optimize Biomass Conversion

- How is the chamber temperature displayed in the muffle furnace? Get Accurate Readings for Your Lab

- How does a microwave heating system compare to traditional muffle furnaces? Fast & Safe Solid Electrolyte Regeneration

- What is the design feature of the furnace chamber and frame in a muffle furnace? Discover the Key to Durability

- Why is a muffle furnace required for SnO2/ZnO composites? Achieve High-Purity Calcination

- How does heat treatment in a muffle furnace enhance MnO2@g-C3N4 performance? Boost Catalytic Efficiency Today

- What are the recommended heating and cooling protocols for a muffle furnace? Ensure Longevity and Safety in Your Lab