The key design feature of a muffle furnace's chamber and frame is their separation. The inner furnace chamber is not rigidly attached to the outer frame; instead, it rests on load-bearing rollers. This allows the chamber to slide freely, expanding and contracting independently from the frame during the extreme temperature changes of heating and cooling cycles.

The core principle is simple but critical: a furnace is not built like a static box. It is an engineered system designed to manage the immense physical stress of thermal expansion, preventing self-destruction and ensuring a long, reliable service life.

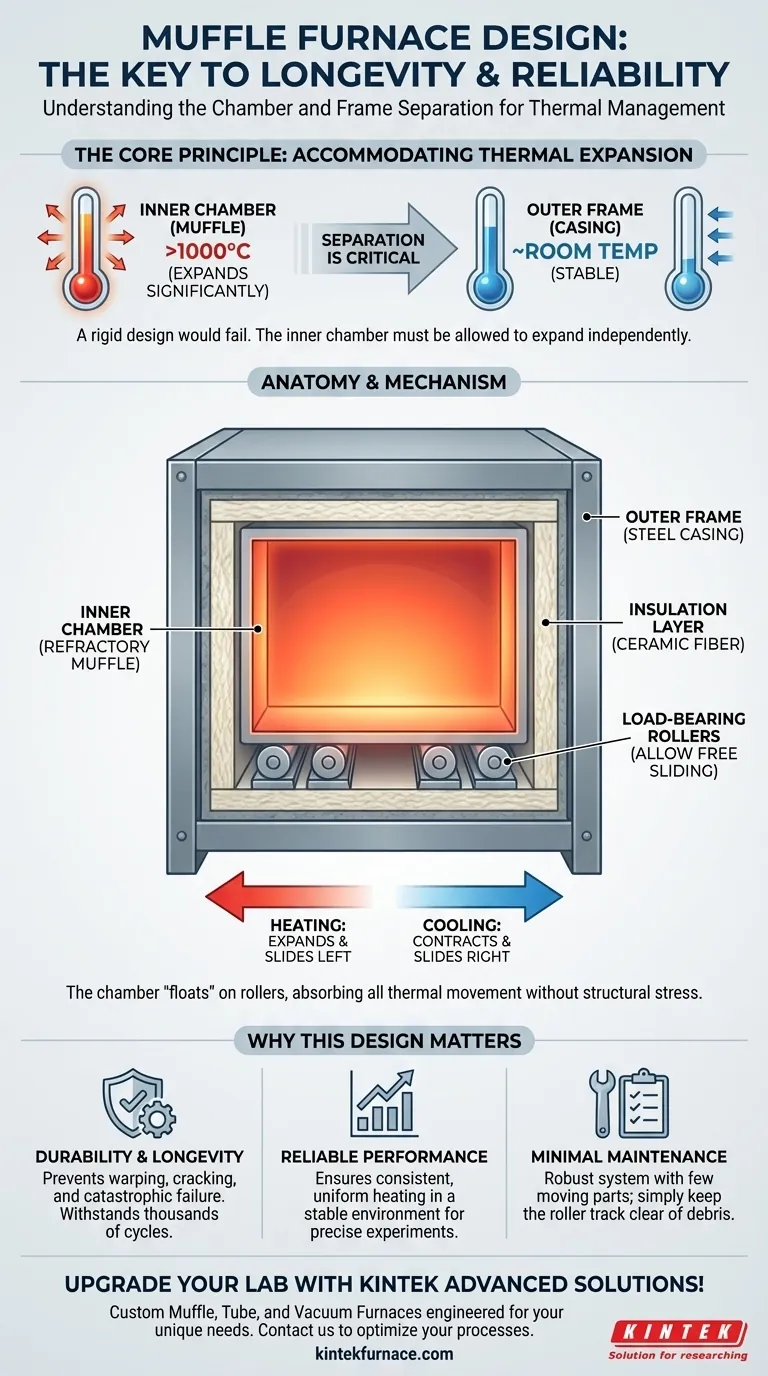

The Principle: Accommodating Thermal Expansion

The entire design philosophy revolves around a single, unavoidable law of physics: materials expand when heated. The temperature difference between the inner chamber and the outer frame is massive, and a rigid design would inevitably fail.

Why Separation is Critical

The inner chamber, or "muffle," can reach temperatures exceeding 1000°C, causing it to expand significantly. In contrast, the external frame remains close to room temperature, thanks to a thick layer of insulation.

If these two components were welded or bolted together, the expanding inner chamber would push against the unmoving outer frame. This would create immense mechanical stress, leading to warped metal, cracked refractory materials, and catastrophic furnace failure.

The Role of Load-Bearing Rollers

To solve this, engineers physically decouple the two components. By placing the heavy inner chamber on rollers, it is allowed to "float" within the external frame.

As the chamber heats up and expands along its length, the rollers allow it to slide smoothly. When it cools and contracts, it slides back. This simple mechanical solution safely absorbs all thermal movement without creating structural stress.

The Impact on Furnace Longevity

This design is fundamental to the durability and reliability of a high-quality muffle furnace. It directly prevents the most common mode of structural failure, ensuring the furnace can withstand thousands of heating and cooling cycles over a long service life with minimal maintenance.

Anatomy of the Key Components

Understanding the function of each part clarifies why their separation is so essential.

The Inner Chamber (The "Muffle")

This is the heart of the furnace. It is typically made of a dense, heat-resistant refractory material like ceramic, alumina, or quartz. Its purpose is to hold the material being heated and provide a chemically inert, uniform temperature environment.

The Outer Frame (The "Casing")

The outer frame is the furnace's structural backbone. Usually made of steel, its job is to provide rigidity, protect the internal components, and support the chamber and its heavy insulation. It is the cool, stable structure that contains the intense heat.

The Insulation Layer

Positioned between the inner chamber and outer frame is a thick layer of high-performance insulation, such as ceramic fiber or mineral wool. This material is what creates the steep temperature gradient, keeping the outer frame cool while the inner chamber is at peak temperature. This insulation makes the decoupled design an absolute necessity.

Understanding the Trade-offs

While this design is superior for high-temperature applications, it is important to recognize the engineering choices involved.

Cost and Complexity

A design featuring a decoupled chamber on rollers is more complex and expensive to manufacture than a simple, single-body welded box. The precision required to ensure smooth movement adds to the cost.

Maintenance Considerations

While robust, any system with moving parts requires some level of awareness. Over a very long service life, the rollers or their tracks could potentially accumulate debris, requiring inspection to ensure they continue to allow free movement.

The Inevitable Flaw of a Rigid Design

The alternative—a simple, rigidly connected design—is only viable for very low-temperature ovens. In a high-temperature muffle furnace, such a design is not a trade-off; it is a guarantee of failure. The cost savings would be quickly erased by the need for frequent, expensive repairs or complete replacement.

What This Design Means for You

Understanding this core engineering principle helps you operate, maintain, and purchase equipment more effectively.

- If your primary focus is operating the furnace: This design ensures reliable, consistent performance. Trust that the furnace is built to handle thermal stress and always follow the manufacturer's recommended procedures for heating and cooling rates.

- If your primary focus is maintenance: Know that the ability of the chamber to move freely is crucial. Periodically ensure the area around the support system is clear of debris that could impede movement.

- If your primary focus is purchasing a new furnace: A decoupled chamber and frame design is a key indicator of a high-quality, durable furnace. It signals that the equipment was engineered for longevity, not just low initial cost.

By appreciating that a furnace is a dynamic system built to manage its own internal forces, you gain a deeper understanding of its quality and operational resilience.

Summary Table:

| Feature | Description |

|---|---|

| Chamber-Frame Separation | Inner chamber rests on rollers, allowing independent expansion and contraction to prevent structural stress. |

| Thermal Expansion Management | Accommodates extreme temperature changes, with inner chamber reaching over 1000°C while outer frame stays cool. |

| Key Components | Includes inner muffle (refractory material), outer frame (steel casing), insulation layer, and load-bearing rollers. |

| Benefits | Enhances durability, prevents warping and cracking, and supports thousands of heating cycles with minimal maintenance. |

Upgrade your laboratory with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems tailored to your unique needs. Our deep customization capabilities ensure precise performance for diverse applications, delivering reliability and longevity. Contact us today to discuss how our innovative designs can optimize your experimental processes and boost efficiency!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency

- What is the role of a muffle furnace in the study of biochar regeneration and reuse? Unlock Sustainable Water Treatment

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis