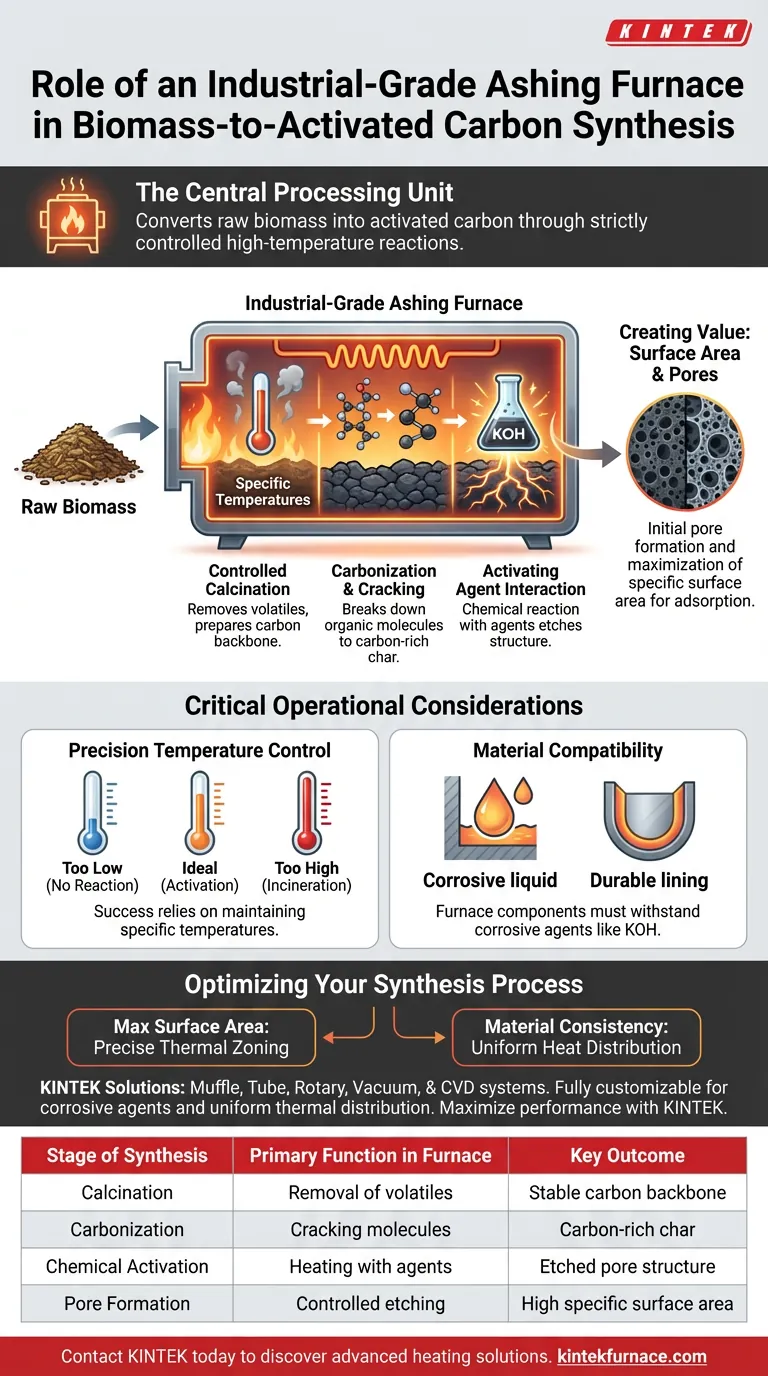

An industrial-grade ashing furnace acts as the central processing unit for converting raw biomass into activated carbon. It provides the strictly controlled high-temperature environment required to calcine raw materials, drive the chemical reactions necessary for carbonization, and engineer the internal pore structure of the final product.

The furnace does not simply burn waste; it orchestrates a precise thermal treatment that cracks carbonaceous substances and reacts them with activating agents. This creates the high specific surface area that defines effective activated carbon.

The Mechanics of Transformation

Controlled Calcination Environment

The primary function of the ashing furnace is to provide a stable, high-heat environment for calcination.

Unlike open combustion, this process subjects the biomass to specific temperatures to remove volatile components. This thermal treatment prepares the carbon backbone for activation.

Carbonization and Cracking

Inside the furnace, the intense heat facilitates the cracking of carbonaceous substances.

Complex organic molecules found in the biomass break down into simpler structures. This step eliminates non-carbon elements, leaving behind a carbon-rich char that serves as the foundation for the final product.

Interaction with Activating Agents

The furnace is the vessel where chemical activation occurs, often involving agents like potassium hydroxide (KOH).

The furnace heats the mixture of biomass and the activating agent to a point where they react chemically. This reaction is critical for etching the carbon structure rather than destroying it.

Creating Value: Surface Area and Pores

Formation of Pore Structures

The defining characteristic of activated carbon is its porosity. The ashing furnace drives the initial formation of these pore structures.

As the activating agents react with the carbon at high temperatures, they create microscopic voids within the material.

Maximizing Specific Surface Area

The ultimate goal of this thermal process is to achieve a high specific surface area.

By controlling the furnace parameters, operators ensure the material creates a vast network of internal surface area. This creates the adsorption capacity required for industrial filtration and purification applications.

Critical Operational Considerations

Precision Temperature Control

The effectiveness of the synthesis relies entirely on maintaining specific temperatures.

If the temperature is too low, the cracking and activation reactions will not occur. If the temperature is too high, the biomass may be incinerated completely, resulting in useless ash rather than activated carbon.

Material Compatibility

Using activating agents like potassium hydroxide introduces a corrosive element to the process.

The furnace lining and components must be capable of withstanding not only high heat but also the aggressive chemical nature of the activation process to prevent equipment degradation.

Optimizing Your Synthesis Process

To ensure successful conversion of biomass into activated carbon, consider your specific production goals:

- If your primary focus is maximum surface area: Prioritize a furnace with precise thermal zoning to control the reaction rate between the biomass and the potassium hydroxide.

- If your primary focus is material consistency: Ensure the furnace provides uniform heat distribution to prevent uneven calcination and inconsistent pore formation.

The ashing furnace is the bridge between raw organic waste and high-value industrial filtration material.

Summary Table:

| Stage of Synthesis | Primary Function in Furnace | Key Outcome |

|---|---|---|

| Calcination | Removal of volatile components via controlled high heat | Stable carbon backbone preparation |

| Carbonization | Cracking of complex organic molecules | Formation of carbon-rich char |

| Chemical Activation | Heating biomass with agents like KOH | Etching of the internal pore structure |

| Pore Formation | Controlled thermal etching and reaction | High specific surface area for adsorption |

Maximize Your Material Performance with KINTEK

Transitioning biomass into high-value activated carbon requires more than just heat—it requires precision engineering. Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, alongside specialized lab high-temp furnaces designed to withstand corrosive activating agents and deliver uniform thermal distribution.

Whether you are scaling production or refining your pore structure, our systems are fully customizable to meet your unique synthesis needs. Contact KINTEK today to discover how our advanced heating solutions can optimize your carbonization and activation processes.

Visual Guide

References

- Dzilal Amir, Nurul Sakinah Engliman. Investigating the synthesis parameters of durian skin-based activated carbon and the effects of silver nanocatalysts on its recyclability in methylene blue removal. DOI: 10.1186/s11671-024-03974-1

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What factors affect the price range of muffle furnaces? Key Drivers for Smart Lab Investment

- Why is a laboratory high-temperature muffle furnace used for BaTiO3? Achieve Optimal Tetragonal Crystalline Phases

- What safety features are commonly found in box furnaces? Essential Protection for Your Lab and Industrial Needs

- What are the energy efficiency considerations for muffle furnaces? Cut Costs with Smart Design

- Why is a laboratory high-temperature muffle furnace necessary for AMCCS production? Ensure Coating Integrity

- How is a Muffle furnace used in environmental treatment? Essential for Waste Analysis and Small-Scale Incineration

- What is the significance of using a box resistance furnace for the 900 °C sintering of high-entropy alloys?

- What is a muffle furnace and how is it designed? Discover Its Clean, High-Temp Heating for Pure Results