At their core, modern box furnaces are equipped with a multi-layered system of safety features designed to protect against thermal, electrical, and atmospheric hazards. Key safety mechanisms include automatic over-temperature protection, power cut-offs linked to the door opening, insulated construction for reduced external temperatures, and systems to manage hazardous fumes or process atmospheres. These features work in concert to ensure the safety of the operator, the equipment, and the surrounding environment.

The safety features of a box furnace are not just a checklist of components; they represent an integrated design philosophy. The goal is to create a system that automatically mitigates the most common risks, from overheating and electrical faults to operator exposure, ensuring a reliably safe operational cycle.

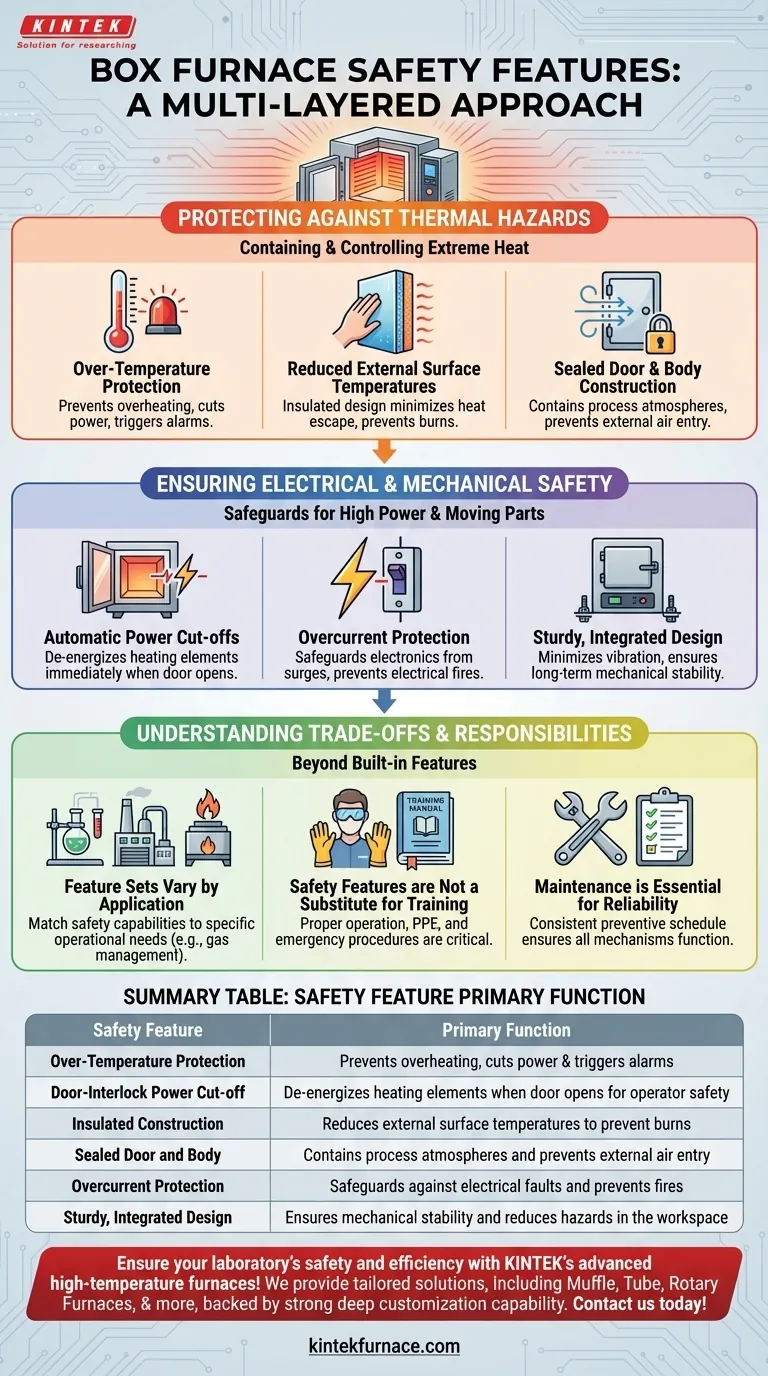

Protecting Against Thermal Hazards

The most immediate risk associated with a box furnace is its extreme heat. Safety features are therefore heavily focused on containing and controlling this thermal energy.

Over-Temperature Protection

An over-temperature alarm is a foundational safety feature. If the furnace exceeds a pre-set maximum temperature due to a control failure, this system triggers an audible or visual alarm and automatically cuts power to the heating elements. This prevents catastrophic damage to the furnace, the product inside, and the facility.

Reduced External Surface Temperatures

Modern furnaces are engineered with a unique outer shell design and internal insulation. This construction minimizes the amount of heat that escapes, which significantly reduces the external surface temperature. This design directly protects operators from accidental contact burns, making the immediate workspace safer.

Sealed Door and Body Construction

To maintain process integrity and safety, box furnaces feature tightly sealed doors and bodies. This design prevents the leakage of process atmospheres (such as inert gases) into the workspace and stops external air from entering the chamber, which could cause a fire or an uncontrolled reaction at high temperatures.

Ensuring Electrical and Mechanical Safety

Beyond heat, the high power requirements and moving parts of a furnace necessitate robust electrical and mechanical safeguards.

Automatic Power Cut-offs

One of the most critical operator safety features is an automatic power cut-off when the furnace door is opened. This interlock immediately de-energizes the heating elements, preventing operator exposure to extreme radiant heat and electrical components. Many systems also include power failure protection that safely shuts down the unit during an outage.

Overcurrent Protection

Similar to a circuit breaker in a building, overcurrent protection safeguards the furnace's sophisticated electronics. If the system draws too much electrical current due to a short circuit or surge, this mechanism automatically shuts down power, preventing damage to internal components and reducing the risk of an electrical fire.

Sturdy, Integrated Design

The physical construction contributes significantly to safety. A sturdy and compact design minimizes vibration and provides long-term stability. This inherent reliability prevents mechanical failures, while an integrated form factor reduces trip hazards and simplifies operation in a busy lab or industrial setting.

Understanding the Trade-offs and Responsibilities

While modern furnaces are incredibly safe, their effectiveness depends on proper selection and use. Relying solely on built-in features without understanding their context can lead to safety gaps.

Feature Sets Vary by Application

Not all box furnaces are created equal. A simple furnace for firing ceramics in an art studio will have different safety features than an industrial furnace used for annealing aerospace components with a flammable hydrogen atmosphere. The latter requires advanced gas leak detectors, fume hoods, and local exhaust systems to manage environmental risk.

Safety Features are Not a Substitute for Training

Automatic shut-offs and alarms are a critical backstop, but they do not replace the need for a well-trained operator. Understanding the specific process, wearing the correct Personal Protective Equipment (PPE), and knowing emergency procedures are non-negotiable aspects of safe operation.

Maintenance is Essential for Reliability

Safety systems are only effective if they work. Sensors can fail, seals can wear out, and interlock switches can become misaligned. A consistent preventive maintenance schedule is crucial to ensure that all safety mechanisms are functioning as designed.

Making the Right Choice for Your Goal

When evaluating a box furnace, match its safety capabilities to your specific operational needs and risks.

- If your primary focus is general laboratory use (e.g., ashing, tempering): Prioritize furnaces with certified over-temperature protection, a door-opening power cut-off, and a cool-touch exterior.

- If your primary focus is industrial material processing (e.g., annealing, sintering): Your requirements must include all basic safety features plus robust atmosphere management, such as sealed chambers and integrated exhaust systems.

- If your primary focus is safety in a multi-user or training environment: Emphasize clear visual alarms, simple controls, and a mechanically stable, integrated design to minimize the potential for operator error.

Ultimately, understanding these integrated safety systems empowers you to select and operate a box furnace with confidence and security.

Summary Table:

| Safety Feature | Primary Function |

|---|---|

| Over-Temperature Protection | Prevents overheating by cutting power and triggering alarms |

| Door-Interlock Power Cut-off | De-energizes heating elements when door opens for operator safety |

| Insulated Construction | Reduces external surface temperatures to prevent burns |

| Sealed Door and Body | Contains process atmospheres and prevents external air entry |

| Overcurrent Protection | Safeguards against electrical faults and prevents fires |

| Sturdy, Integrated Design | Ensures mechanical stability and reduces hazards in the workspace |

Ensure your laboratory's safety and efficiency with KINTEK's advanced high-temperature furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with tailored solutions including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability precisely meets your unique experimental requirements, enhancing operational security and performance. Contact us today to discuss how our products can benefit your specific applications!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Molybdenum Vacuum Heat Treat Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- How is a Vertical Tube Furnace used for fuel dust ignition studies? Model Industrial Combustion with Precision

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis