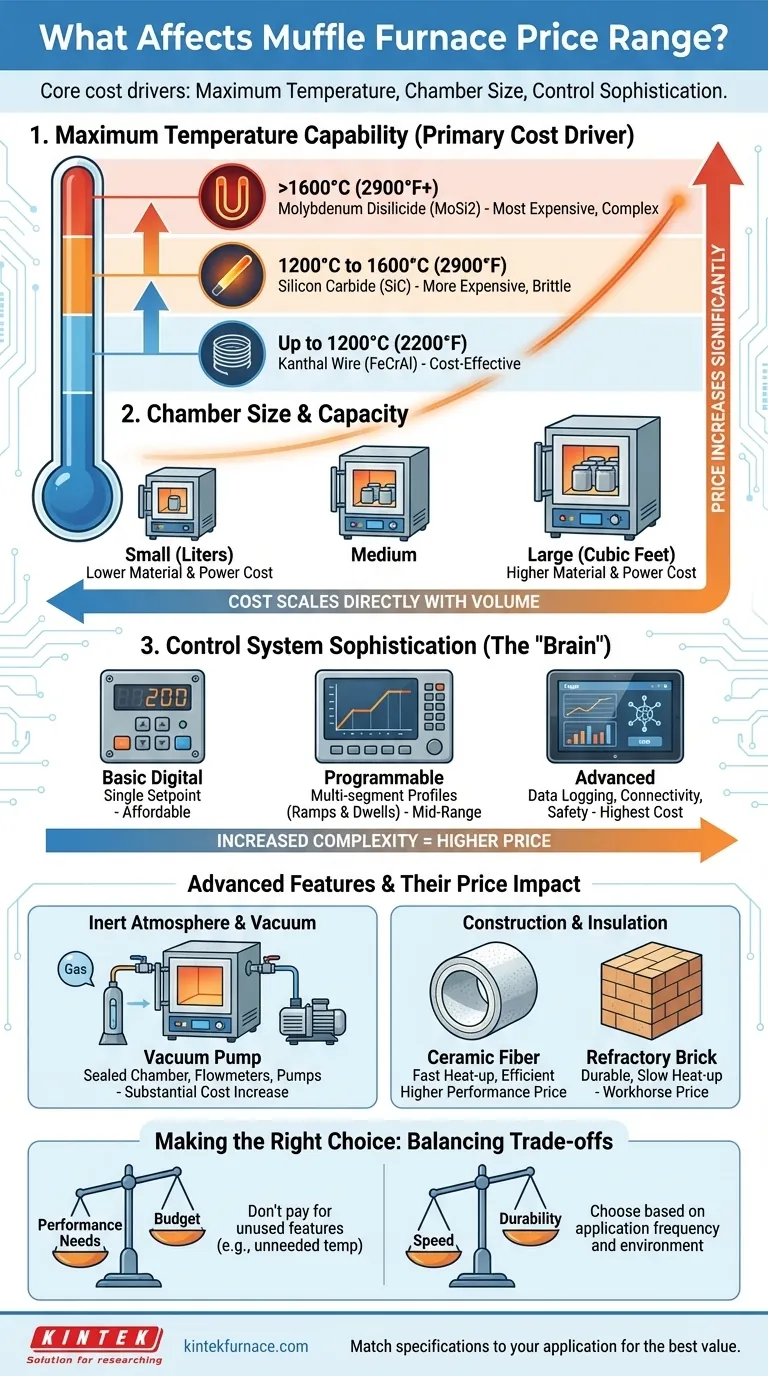

The price of a muffle furnace is directly tied to its maximum temperature, internal chamber size, and the sophistication of its control system. These three factors represent the primary cost drivers. Secondary features, such as the ability to control the internal atmosphere or the overall quality of insulation and construction, further define the final price, which can range from a few hundred dollars for a small, basic unit to tens of thousands for a high-performance research furnace.

Understanding the price drivers of a muffle furnace is about more than just budget. It is about precisely matching the furnace's technical capabilities to your specific application to ensure you are paying for performance you actually need, and not for features you will never use.

The Core Cost Drivers Explained

The vast price range exists because a "muffle furnace" can describe anything from a simple kiln for hobbyists to a precision instrument for aerospace materials science. Each component's specification has a direct impact on cost.

Maximum Temperature Capability

The single greatest factor in a furnace's cost is its maximum achievable temperature. As the temperature requirement increases, the materials required for the heating elements and insulation become more exotic and expensive.

- Up to 1200°C (2200°F): Most furnaces in this range use durable Kanthal (FeCrAl) wire elements. This is the most common and cost-effective type for general-purpose lab work, heat treating, and ashing.

- 1200°C to 1600°C (2900°F): Reaching these temperatures requires silicon carbide (SiC) heating elements, which are more expensive and brittle than wire elements.

- Above 1600°C (2900°F+): High-temperature applications demand molybdenum disilicide (MoSi2) elements. These are the most expensive, requiring sophisticated control systems to manage their performance characteristics.

Chamber Size and Capacity

This is a straightforward driver: a larger internal chamber requires more insulation, more powerful heating elements, and a more robust steel frame. The cost scales directly with the internal volume, measured in liters or cubic feet.

Control System Sophistication

The furnace's "brain" is a major point of price differentiation.

- Basic Digital Control: A simple controller allows you to set a single target temperature. This is the most affordable option, suitable for processes where you heat to one temperature and hold it.

- Programmable Control: A more advanced, multi-segment programmable controller allows you to create complex heating profiles with multiple ramps (rate of heating/cooling) and dwells (holding at a temperature). This is essential for advanced materials processing and research.

- Advanced Features: Top-tier controllers add data logging, USB or Ethernet connectivity for computer control, and advanced safety interlocks, all of which increase the cost.

A Note on the "Muffle"

Historically, a "muffle" was a ceramic insert that protected the workpiece from the soot and gas of a combustion-fired furnace. With modern electrical heating, there is no combustion. The terms muffle furnace and chamber furnace are now used interchangeably to describe any front-loading, box-shaped furnace.

Advanced Features and Their Price Impact

Beyond the core specifications, specialized features can add significantly to the furnace's price. These are typically required for specific scientific or industrial processes.

Inert Atmosphere and Gas Control

A standard furnace operates in an air atmosphere. If your process requires preventing oxidation (e.g., when working with certain metals), you need an atmosphere-controlled furnace. This involves a sealed chamber, gas inlet/outlet ports, and flowmeters, which substantially increase complexity and cost.

Vacuum Capability

Creating a vacuum is even more demanding. It requires a furnace with a very robust, often cylindrical chamber, specialized vacuum-tight seals, and an external vacuum pump system. A vacuum furnace is a highly specialized piece of equipment and represents a major step up in price.

Construction and Insulation Quality

The quality of the build affects both price and performance. Furnaces with high-density, durable refractory brick insulation are heavy and heat up slowly but are extremely durable. Furnaces with lightweight ceramic fiber insulation heat up and cool down much faster and are more energy-efficient, often commanding a higher price for their performance benefits.

Understanding the Trade-offs

Choosing a furnace means balancing capability with budget. Paying for unneeded features is the most common purchasing mistake.

Performance vs. Budget

Do not pay for a 1700°C furnace if your process never exceeds 1100°C. The cost difference between a standard 1200°C furnace and a high-temperature model is significant. Carefully define your maximum required temperature and add a small safety margin (e.g., 50-100°C).

Speed vs. Durability

A lightweight ceramic fiber furnace offers fast heat-up rates, which is ideal for a busy lab with varied processes. A heavy firebrick furnace heats slowly but can withstand more mechanical and chemical abuse, making it a workhorse for harsh industrial applications.

General-Purpose vs. Specialized

A basic box furnace is a versatile tool. An atmosphere-controlled or vacuum furnace is a specialized instrument. If you only need atmosphere control for a small percentage of your work, it may be more cost-effective to buy a standard furnace and a separate, smaller tube furnace specifically for those tasks.

Selecting the Right Furnace for Your Application

To make an informed decision, let your primary application guide your choice.

- If your primary focus is general heat treating, ashing, or materials testing: A standard box furnace with a maximum temperature of 1100-1200°C is your most cost-effective choice.

- If your primary focus is research with complex thermal profiles: Prioritize a furnace with a multi-segment programmable controller and consider data logging capabilities.

- If your primary focus is working with oxygen-sensitive materials: You must invest in a furnace with atmosphere control, which significantly increases the base cost.

- If your primary focus is high-temperature ceramics or advanced material sintering: Your selection will be dictated by the maximum temperature required, likely pushing you into models with SiC or MoSi2 elements.

By aligning the furnace's specifications with your true operational needs, you can secure the right tool for the job at a price that makes sense.

Summary Table:

| Factor | Impact on Price | Key Details |

|---|---|---|

| Maximum Temperature | High | Higher temps require costlier elements (e.g., Kanthal, SiC, MoSi2) |

| Chamber Size | Moderate | Larger chambers need more materials and power, increasing cost |

| Control System | High | Basic digital to advanced programmable controllers add expense |

| Advanced Features | Variable | Atmosphere control, vacuum, insulation quality drive up prices |

Ready to find the perfect muffle furnace for your lab? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all with deep customization capabilities to meet your unique experimental requirements. Contact us today to discuss how we can enhance your lab's performance and efficiency!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency