At its core, a muffle furnace is a high-temperature oven that uses a simple but critical design feature: an inner chamber, or "muffle," that isolates the material being heated from the actual heating elements. This separation prevents contamination from combustion byproducts or the elements themselves, ensuring a chemically pure heating environment and precise temperature control.

The defining principle of a muffle furnace is not just achieving high temperatures, but doing so with exceptional cleanliness. Its design physically separates the heat source from the sample, making it essential for processes where material purity is paramount.

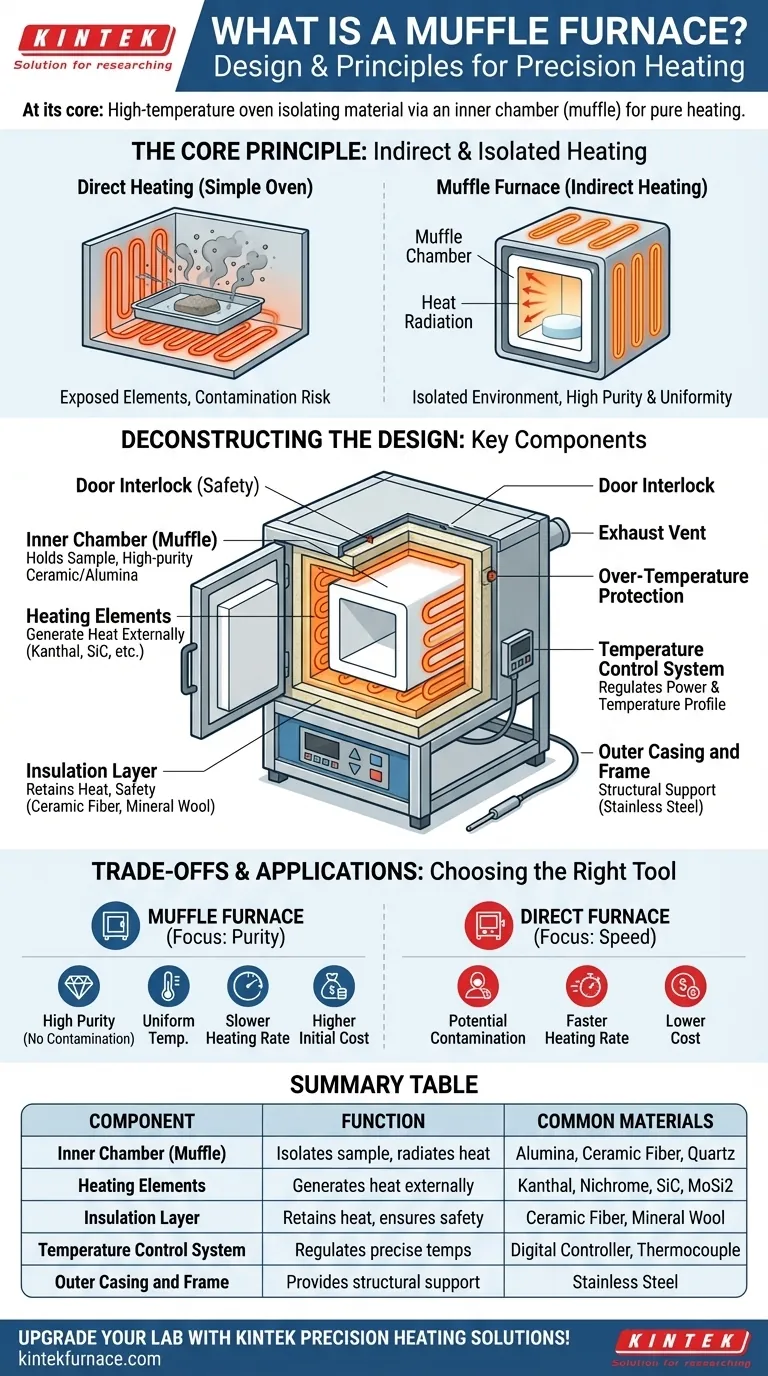

The Core Principle: Indirect and Isolated Heating

The unique value of a muffle furnace comes from its method of heat transfer. Unlike a simple oven where heating elements may be exposed, the muffle design creates a controlled, isolated environment.

The Role of the "Muffle"

The "muffle" is the central component. It is a box-like chamber made of a highly heat-resistant material like ceramic or alumina that contains the sample.

The heating elements are located on the outside of this muffle. They heat the chamber, which then radiates thermal energy evenly and cleanly to the material inside.

Preventing Contamination

This indirect heating method is the furnace's primary advantage. It creates a barrier that prevents any particles from the heating elements or gases from a fuel source from coming into contact with the sample.

This is critical in applications like ashing, gravimetric analysis, or materials research, where even trace amounts of contamination can ruin an experiment.

Ensuring Temperature Uniformity

By heating the entire muffle chamber, which then radiates heat inward, the furnace creates a highly uniform temperature zone. This helps ensure that the entire sample is heated evenly, reducing hot or cold spots that could affect results.

Deconstructing the Design: Key Components

A muffle furnace is an assembly of specialized parts, each with a distinct purpose, working together to provide controlled, clean heat.

The Inner Chamber (Muffle)

This is the workhorse of the furnace. It's typically made of high-purity, refractory materials like alumina, ceramic fiber, or quartz. The choice of material depends on the maximum required temperature and chemical compatibility with the samples.

The Heating Elements

These components generate the heat. They are made from high-resistance materials like Kanthal (an iron-chromium-aluminum alloy), nichrome, silicon carbide (SiC), or molybdenum disilicide (MoSi2). They are wrapped around the outside of the muffle, never touching the sample directly.

The Insulation Layer

To achieve high temperatures efficiently and keep the exterior safe to touch, muffle furnaces are heavily insulated. This layer, made of ceramic fiber or mineral wool, is sandwiched between the inner chamber and the outer casing.

The Temperature Control System

Modern furnaces use a digital controller connected to a temperature sensor (like a thermocouple) placed near the muffle. This system precisely regulates the power sent to the heating elements to maintain the desired temperature profile.

The Outer Casing and Frame

This is the rigid metal shell, often made of stainless steel, that provides structural integrity. In some designs, the inner chamber is placed on rollers to allow it to expand and contract freely during heating and cooling cycles, preventing stress on the furnace frame.

Safety and Utility Features

Most units include a door interlock that cuts power when opened, over-temperature protection, and an exhaust vent to safely remove any gases produced by the sample during heating. Some may also have a quartz observation window.

Understanding the Trade-offs

While powerful, the muffle furnace design has inherent limitations that are important to understand.

Slower Heating Rates

Because the heat must first saturate the muffle chamber before it can be radiated to the sample, the heating process is inherently slower than in a direct-heating furnace. This can increase cycle times.

Muffle Material Limitations

The muffle itself is a consumable component over the long term. It can be susceptible to thermal shock (cracking if temperature changes too rapidly) or chemical reactions with certain aggressive samples.

Higher Initial Cost

The complex, multi-layered construction and high-purity materials typically make muffle furnaces more expensive than simpler laboratory ovens or direct-heating furnaces.

Is a Muffle Furnace Right for Your Application?

Choosing the right furnace depends entirely on your process requirements. The decision balances the need for purity against the need for speed and cost.

- If your primary focus is material purity and avoiding contamination: A muffle furnace is the definitive and correct choice for applications like ashing, trace metal analysis, or creating high-purity glass.

- If your primary focus is maximum heating speed for robust materials: A direct-heating furnace may be a more efficient option, as long as minor contamination from the elements is not a concern.

- If your primary focus is processing under a specific gas atmosphere: Select a muffle furnace specifically designed with a sealed chamber and gas ports to enable precise atmospheric control.

Ultimately, the choice of a muffle furnace is a decision for precision and purity over raw operational speed.

Summary Table:

| Component | Function | Common Materials |

|---|---|---|

| Inner Chamber (Muffle) | Isolates sample from heating elements for purity | Alumina, ceramic fiber, quartz |

| Heating Elements | Generates heat externally | Kanthal, nichrome, silicon carbide, molybdenum disilicide |

| Insulation Layer | Retains heat and ensures safety | Ceramic fiber, mineral wool |

| Temperature Control System | Regulates and maintains precise temperatures | Digital controller with thermocouple |

| Outer Casing and Frame | Provides structural support | Stainless steel |

Upgrade your lab with precision heating solutions from KINTEK! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capability to precisely meet your unique experimental requirements. Contact us today to discuss how our muffle furnaces can enhance your material purity and efficiency!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis

- What metals cannot be heated by induction? Understanding Material Suitability for Efficient Heating

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation