At its core, a muffle furnace is used in environmental treatment to break down waste materials through intense, controlled heat. This high-temperature processing, primarily through a process called ashing, separates organic and volatile substances from the inorganic components, allowing for detailed analysis, purification, and effective management of materials like sewage sludge and solid waste.

A muffle furnace provides a high-purity, high-heat environment to thermally decompose waste. This reduces complex materials to simple, stable ash, which can then be analyzed for contaminants or safely disposed of, making it an indispensable tool for environmental testing and small-scale treatment.

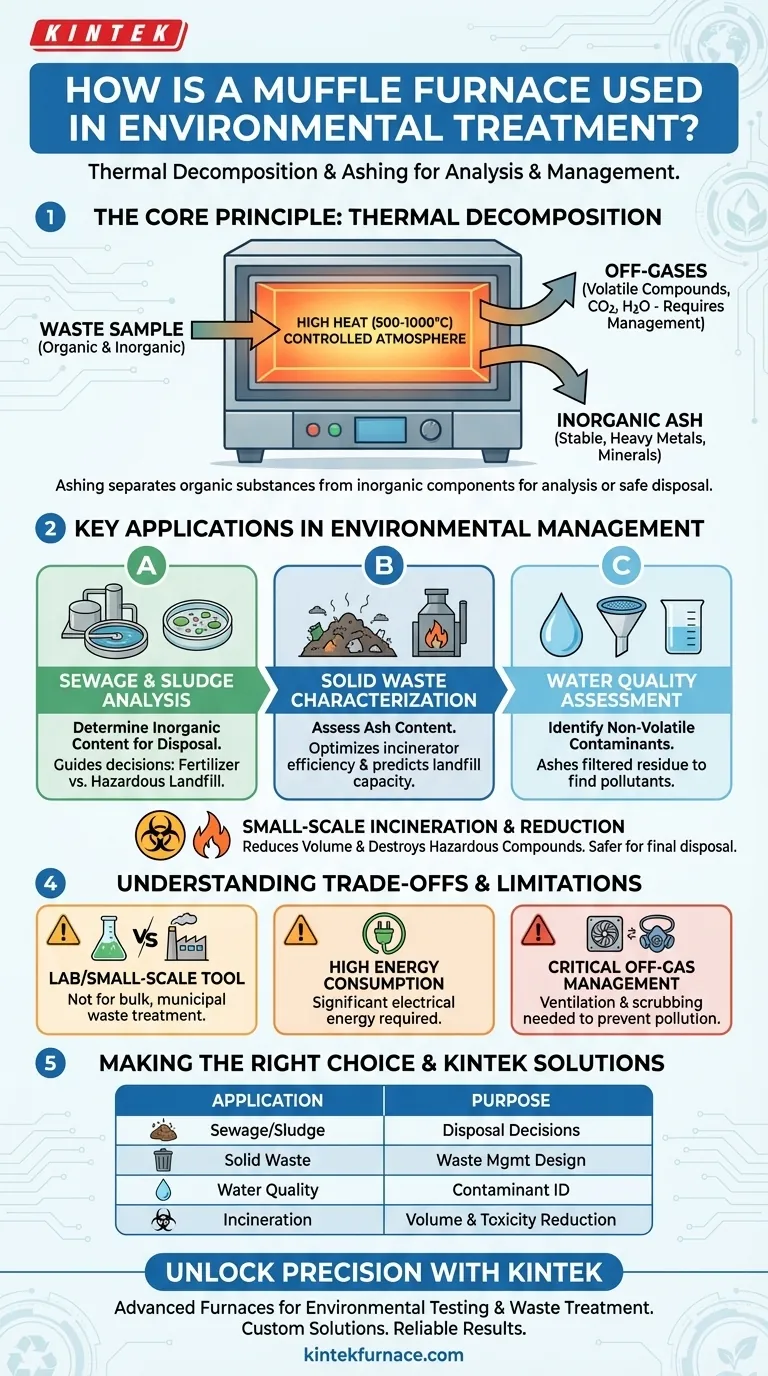

The Core Principle: Thermal Decomposition

A muffle furnace is essentially a high-temperature oven where the material being heated is isolated from the direct flame or heating elements. This "muffle" creates a clean, controlled atmosphere crucial for precise results.

The Process of Ashing

The primary function of a muffle furnace in environmental settings is ashing. This is the process of burning off all organic and volatile components from a sample at very high temperatures (typically 500-1000°C).

What remains is the inorganic ash, a stable material containing elements like heavy metals and minerals.

How Ashing Aids Environmental Analysis

By converting a complex waste sample into simple ash, laboratories can accurately analyze its composition. This is the foundation of its use in environmental science.

For example, analyzing the ash can reveal the precise concentration of toxic heavy metals like lead, mercury, or cadmium in a sample of industrial sludge. This data is critical for determining how the waste must be treated and disposed of to prevent environmental contamination.

Incineration for Waste Reduction

Beyond analysis, the furnace can be used for the small-scale incineration of hazardous biological or chemical waste.

This process drastically reduces the volume of the waste and destroys harmful organic compounds, rendering the material more stable and safer for final disposal.

Key Applications in Environmental Management

The principle of ashing and thermal decomposition is applied to several key areas of environmental treatment and monitoring.

Sewage and Sludge Analysis

Muffle furnaces are routinely used to ash samples of sewage sludge. The resulting data on inorganic content helps operators of wastewater treatment plants make critical decisions.

This analysis informs strategies for sludge disposal, such as its potential use as agricultural fertilizer (if contaminant levels are low) or the need for hazardous waste landfilling (if contaminant levels are high).

Solid Waste Characterization

Determining the ash content of municipal or industrial solid waste is vital for designing effective large-scale waste management systems.

Engineers use this data to calculate the efficiency of incinerators, predict the amount of ash that will be generated in a waste-to-energy plant, and manage landfill capacity.

Water Quality Assessment

While a furnace doesn't treat liquid water directly, it is used to prepare samples for water quality assessment.

Solids filtered from a water sample, or the residue left after evaporating the water, can be ashed in a muffle furnace. Subsequent analysis of the ash can identify non-volatile inorganic contaminants that were present in the original water source.

Understanding the Trade-offs

While powerful, a muffle furnace is a specific tool with inherent limitations that are important to understand.

A Tool for Analysis, Not Bulk Treatment

A muffle furnace is a laboratory or small-scale industrial instrument. It is designed for analyzing samples or treating small batches of specialized waste, not for processing the large volumes handled by a municipal incinerator.

High Energy Consumption

Reaching and maintaining temperatures of over 500°C requires a significant amount of electrical energy. This makes the process energy-intensive and contributes to its operational cost.

Off-Gas Management is Critical

The thermal decomposition of waste materials releases various gases, known as off-gases. These can include carbon dioxide, water vapor, and potentially toxic fumes, depending on the original material.

Proper ventilation and, in some cases, exhaust gas "scrubbing" systems are mandatory to ensure that the treatment process does not create a secondary air pollution problem.

Making the Right Choice for Your Goal

The application of a muffle furnace depends entirely on your end objective.

- If your primary focus is analytical testing: Use the muffle furnace for precise ashing to determine the exact inorganic and heavy metal composition of waste, sludge, or soil samples.

- If your primary focus is small-scale waste treatment: Employ the furnace for the complete incineration of small quantities of hazardous biological or chemical materials to reduce their volume and toxicity.

- If your primary focus is process design: Leverage the analytical data from furnace testing to inform the engineering and operational parameters of large-scale waste management facilities.

Ultimately, the muffle furnace provides the critical ability to look inside a waste material, understand its fundamental composition, and make informed decisions for its safe management.

Summary Table:

| Application | Purpose | Key Process |

|---|---|---|

| Sewage/Sludge Analysis | Determine inorganic content for disposal decisions | Ashing at 500-1000°C |

| Solid Waste Characterization | Assess ash content for waste management | Thermal decomposition |

| Water Quality Assessment | Identify non-volatile contaminants | Sample preparation via ashing |

| Small-Scale Incineration | Reduce volume and toxicity of hazardous waste | High-temperature incineration |

Unlock Precision in Environmental Treatment with KINTEK

Struggling with accurate waste analysis or safe disposal? KINTEK's advanced high-temperature furnace solutions, including Muffle, Tube, and Rotary Furnaces, are engineered to deliver precise thermal decomposition and ashing for your laboratory needs. With our strong deep customization capability, we tailor each furnace to meet your unique experimental requirements, ensuring reliable results in environmental testing, sludge analysis, and small-scale waste treatment.

Why Choose KINTEK?

- Expert R&D and In-House Manufacturing: Guaranteeing quality and innovation in every product.

- Comprehensive Product Line: From Vacuum & Atmosphere Furnaces to CVD/PECVD Systems, we have the right tool for your application.

- Custom Solutions: We adapt our technology to fit your specific challenges, enhancing efficiency and safety.

Ready to enhance your environmental management processes? Contact us today to discuss how our furnaces can support your goals in waste reduction and contaminant analysis!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis

- What metals cannot be heated by induction? Understanding Material Suitability for Efficient Heating

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency