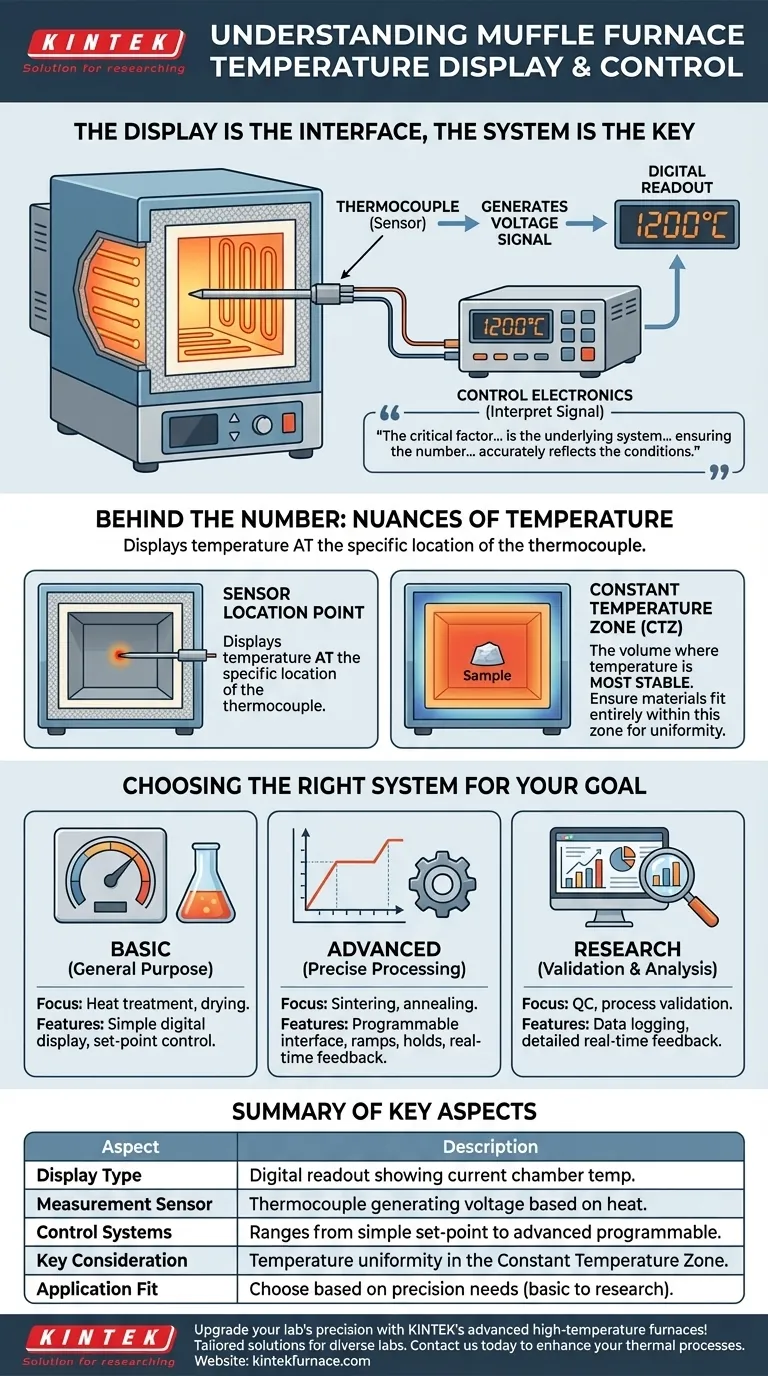

In its most basic form, a muffle furnace indicates its internal chamber temperature on a simple digital display. This readout provides a direct window into the current thermal state of the furnace. However, this single display is often the front end for a range of control systems, from simple set-point controllers to more advanced, programmable packages.

The digital display is merely the interface. The critical factor for any precise thermal process is the underlying system of temperature measurement and control that feeds the display, ensuring the number you see accurately reflects the conditions your material is experiencing.

How Temperature is Measured and Controlled

Understanding the temperature display requires looking at the system behind it. The number on the screen is the final output of a process that starts with a physical sensor.

The Role of the Thermocouple

The furnace doesn't inherently "know" its own temperature. A physical sensor, typically a thermocouple, is placed inside the chamber to measure the heat.

This thermocouple generates a tiny voltage that corresponds directly to the temperature it senses. The furnace's control electronics interpret this voltage signal and translate it into the degree value shown on the display.

The Display as a Control Interface

For basic models, the digital display simply shows the current temperature. The user may have a separate dial or buttons to set a target temperature.

More advanced control packages integrate the display into a programmable interface. This allows users to set ramps, holds, and complex temperature profiles, with the display providing real-time feedback on the cycle's progress.

Understanding the Key Nuances

The displayed temperature is a critical data point, but it is not the complete story. Achieving a successful outcome depends on understanding what that number truly represents.

Displayed Temperature vs. Uniform Temperature

The number on the display represents the temperature at the specific location of the thermocouple. While muffle furnaces are designed for high uniformity, minor temperature variations can exist across the chamber.

The Importance of the "Constant Temperature Zone"

Every furnace has a constant temperature zone, which is the volume within the chamber where the temperature is most stable and uniform. This zone is typically smaller than the overall chamber dimensions.

To ensure your material is heated evenly and accurately, you must ensure it fits entirely within this constant temperature zone. Placing a sample too close to the door or walls may expose it to slightly different temperatures than what is shown on the display.

Insulation and Chamber Integrity

The furnace's ability to maintain a uniform temperature relies on its high-performance insulation and the isolated muffle chamber. This design shields the sample from direct contact with heating elements, which prevents contamination and thermal shock.

Making the Right Choice for Your Goal

The level of control and display sophistication you need is tied directly to your application.

- If your primary focus is general-purpose heat treatment or drying: A standard furnace with a simple digital display and set-point control is often sufficient.

- If your primary focus is precise materials processing like sintering or annealing: An advanced control package with a programmable display is essential for accuracy and repeatability.

- If your primary focus is process validation or research: A system that provides data logging and detailed real-time feedback, in addition to a clear display, is necessary for quality control and analysis.

Ultimately, your decision should be guided by the precision your process demands, not just the presence of a digital display.

Summary Table:

| Aspect | Description |

|---|---|

| Display Type | Digital readout showing current chamber temperature |

| Measurement Sensor | Thermocouple generating voltage based on heat |

| Control Systems | Ranges from simple set-point to advanced programmable interfaces |

| Key Consideration | Temperature uniformity in the constant temperature zone |

| Application Fit | Choose based on precision needs: basic for heat treatment, advanced for sintering |

Upgrade your lab's precision with KINTEK's advanced high-temperature furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored solutions like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures your unique experimental requirements are met with accuracy and reliability. Contact us today to discuss how our products can enhance your thermal processes and drive your research forward!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- Why is re-calcination in a muffle furnace necessary for photocatalysts? Restore Efficiency via Thermal Oxidation

- What is the function of a muffle furnace in SiCf/Al-Mg pretreatment? Optimize Fiber Bonding with Thermal De-sizing

- What is the core function of a muffle furnace in CuO nanoparticle synthesis? Achieve Precision Calcination

- What is the primary function of a muffle furnace in iron-modified activated carbon prep? Optimize Adsorption Sites

- What key step does a Muffle Furnace perform in the determination of mineral content in Tenebrio molitor larvae?