The recommended protocol for a muffle furnace is to follow a programmed, gradual heating ramp rate and to always allow the furnace to cool down naturally with the door closed. Abrupt temperature changes, especially rapid cooling, are the primary cause of damage to the furnace's internal chamber and heating elements.

Your core objective when operating a muffle furnace is not just to reach a target temperature, but to manage thermal stress. The guiding principle is to avoid thermal shock by ensuring all temperature changes—both heating and cooling—are gradual and controlled.

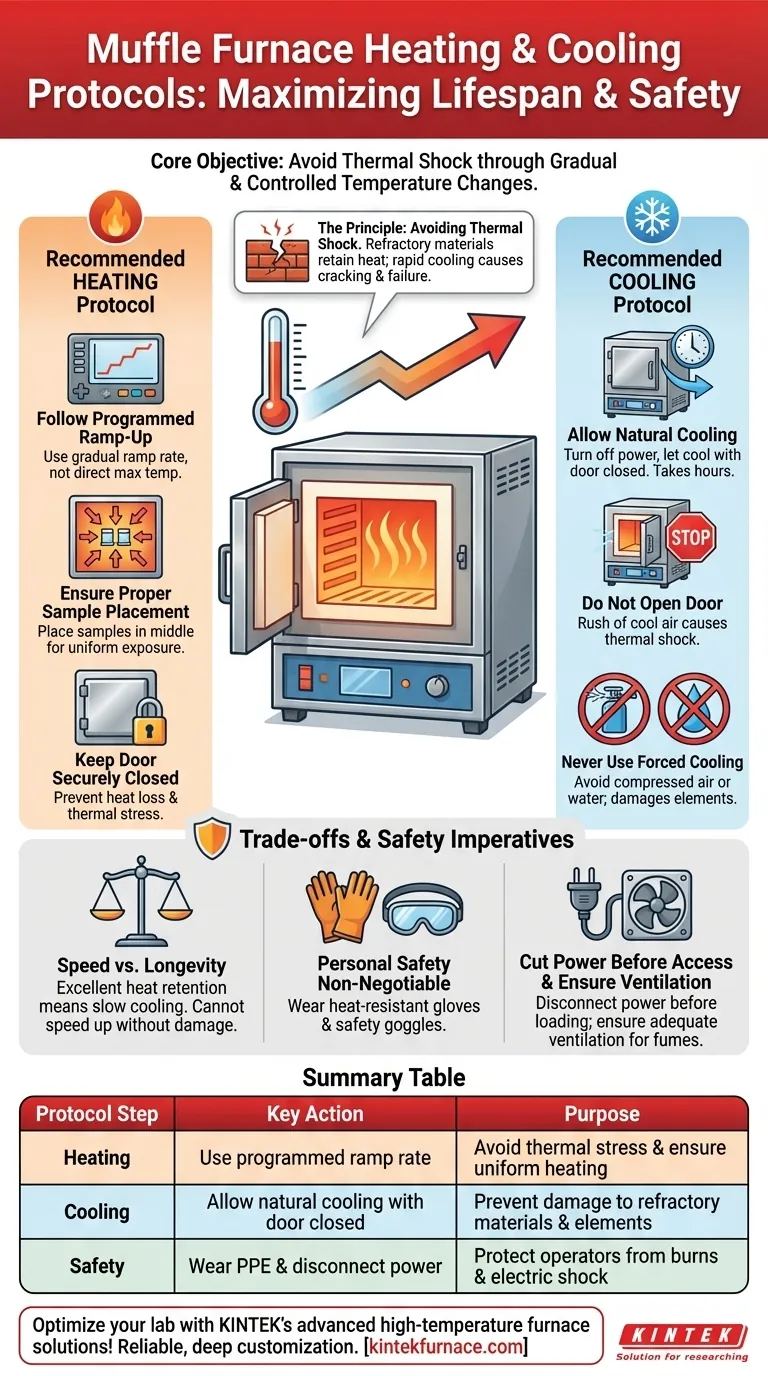

The Principle: Avoiding Thermal Shock

The design of a muffle furnace prioritizes reaching and maintaining extremely high temperatures efficiently. This design directly influences the correct operating protocols for heating and cooling.

The Role of Refractory Materials

Muffle furnaces are built with heavy insulation and refractory brick linings. These materials are exceptional at retaining heat, which allows the furnace to operate at temperatures up to 1800°C without massive energy loss.

However, these dense materials store a tremendous amount of thermal energy. They cannot dissipate this heat quickly without cracking or degrading.

What is Thermal Shock?

Thermal shock occurs when a rapid change in temperature creates mechanical stress within a material. In a muffle furnace, introducing cool air into a hot chamber (by opening the door) or attempting to force-cool the exterior can cause the inner lining to contract unevenly, leading to cracks and catastrophic failure.

Recommended Heating Protocol

A controlled heating cycle is essential for both the sample being processed and the longevity of the furnace itself.

Follow the Manufacturer's Program

Your furnace's controller is designed to manage heating rates. Always use a programmed ramp-up schedule rather than setting the furnace directly to its maximum temperature. A slow, steady increase in heat is always safer.

Ensure Proper Sample Placement

Before starting, place your samples in the middle of the furnace chamber. Arrange them neatly to ensure uniform heat exposure.

Keep the Door Securely Closed

Once the cycle begins, the door should remain closed. Opening the door during the heating process causes significant heat loss and can introduce thermal stress.

Recommended Cooling Protocol

The cooling phase is where most preventable damage occurs. The rule is simple and absolute.

Allow the Furnace to Cool Naturally

After the heating cycle is complete, the only correct procedure is to turn off the power and allow the furnace to cool on its own. This process can take several hours, or even overnight, depending on the furnace size and peak temperature.

Do Not Open the Door

Resist the urge to open the furnace door to speed up cooling. The rush of cooler ambient air is the primary cause of thermal shock to the chamber lining.

Never Use Forced Cooling

Under no circumstances should you use compressed air, water, or any other method to actively cool the furnace. This will almost certainly damage the refractory materials and heating elements.

Understanding the Trade-offs and Safety Imperatives

Operating a muffle furnace requires accepting its inherent design trade-offs and prioritizing safety above all else.

The Speed vs. Longevity Trade-off

The furnace's excellent heat retention is why it is efficient, but it is also why it cools slowly. You cannot have both rapid cooling and a long-lasting furnace. Attempting to speed up the cooling process is a direct trade-off against the equipment's lifespan.

Personal Safety is Non-Negotiable

The extreme temperatures present a significant hazard. Always wear heat-resistant gloves and safety goggles when handling items near the furnace.

Cut Power Before Accessing the Chamber

Always ensure the main power supply is disconnected before loading or unloading samples. This prevents the risk of electric shock from the exposed heating elements.

Ensure Proper Ventilation

Some processes can release fumes or aggressive gases. Your lab must have adequate ventilation to safely manage any potential off-gassing from the materials being heated.

Making the Right Choice for Your Goal

Your operational focus will determine which protocol to emphasize.

- If your primary focus is equipment longevity: Always allow the furnace to cool down naturally to room temperature with the door closed before opening it.

- If your primary focus is operator safety: Always wear appropriate PPE and completely disconnect the power before reaching into the chamber.

- If your primary focus is process repeatability: Always use a calibrated furnace and a pre-programmed heating ramp rate for consistent results.

Ultimately, treating the furnace with respect for its materials and thermal properties is the key to safe, effective, and long-term operation.

Summary Table:

| Protocol Step | Key Action | Purpose |

|---|---|---|

| Heating | Use programmed ramp rate | Avoid thermal stress and ensure uniform heating |

| Cooling | Allow natural cooling with door closed | Prevent damage to refractory materials and elements |

| Safety | Wear PPE and disconnect power | Protect operators from burns and electric shock |

Optimize your lab's performance with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable muffle, tube, rotary, vacuum, atmosphere furnaces, and CVD/PECVD systems. Our strong deep customization capability ensures precise solutions for your unique experimental needs. Contact us today to discuss how our products can enhance your efficiency and safety!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the purpose of heating a precursor solution to 80 °C and 300 rpm stirring? Achieve High-Entropy Uniformity

- What is the primary function of a high-temperature box resistance furnace? Optimize Superalloy Homogenization

- What is the function of a muffle furnace in SiCf/Al-Mg pretreatment? Optimize Fiber Bonding with Thermal De-sizing

- What key step does a Muffle Furnace perform in the determination of mineral content in Tenebrio molitor larvae?

- What is the core role of a muffle furnace in the synthesis of calcium oxide from eggshells? Achieve High-Purity CaO