In industrial heat treating, muffle furnaces are essential for processes that demand high precision and a contamination-free environment. They are widely used for annealing, hardening, sintering, brazing, drawing (tempering), and stress relieving small- to medium-sized metal components across various high-tech sectors.

The core value of a muffle furnace lies in its design. The internal chamber, or "muffle," isolates the workpiece from direct contact with heating elements, ensuring exceptionally uniform heat and preventing contamination from combustion byproducts, which is critical for sensitive materials and controlled atmosphere treatments.

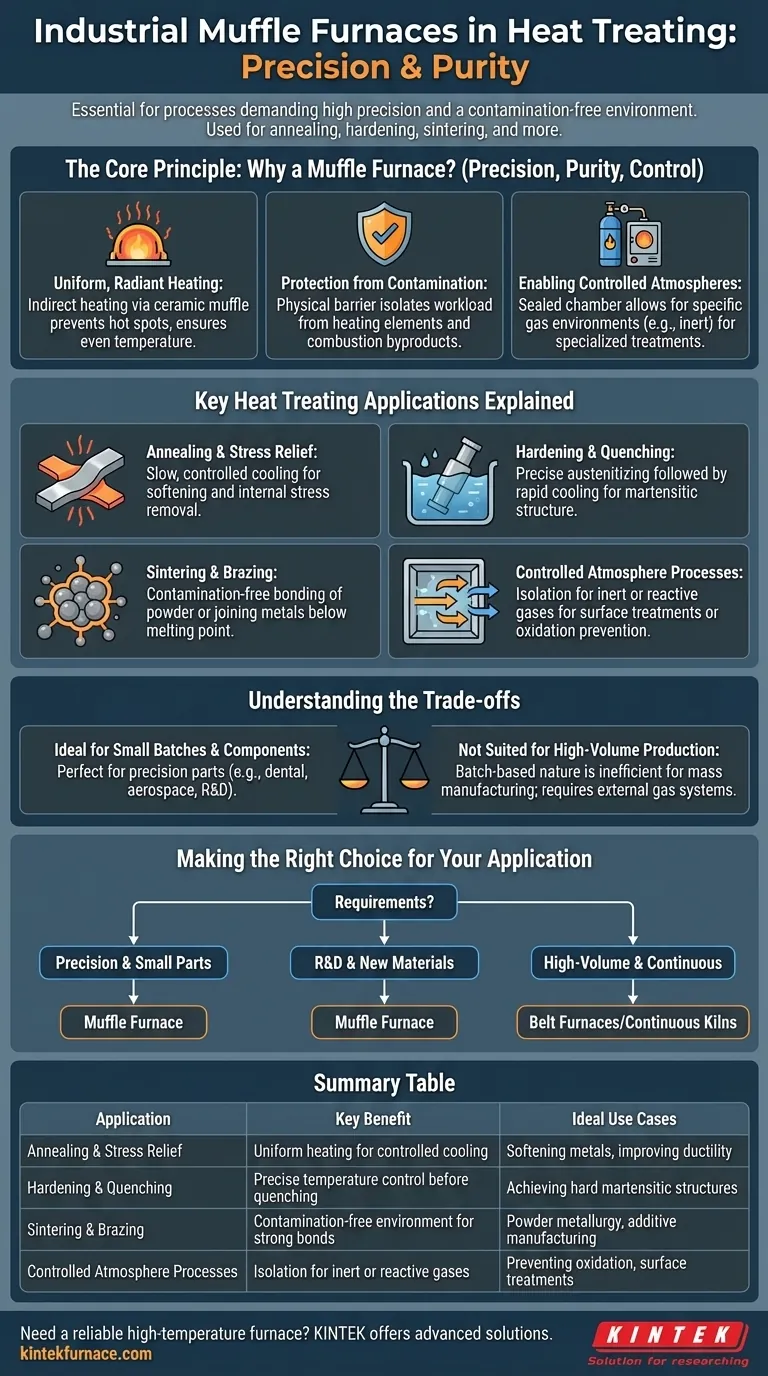

The Core Principle: Why a Muffle Furnace?

Understanding why a muffle furnace is chosen over other heating methods comes down to three key advantages: precision, purity, and control.

Uniform, Radiant Heating

The muffle, typically made of high-temperature ceramic, heats up and radiates thermal energy evenly onto the workpiece. This indirect heating method eliminates hot spots that can occur with direct flame or element exposure. The result is a highly uniform temperature profile, crucial for predictable metallurgical transformations.

Protection from Contamination

The physical barrier of the muffle separates the workload from the heating elements and any potential contaminants. In fuel-fired furnaces, this prevents combustion gases from reacting with the metal's surface. In electric furnaces, it prevents element flaking or oxidation from settling on the parts.

Enabling Controlled Atmospheres

Because the chamber is sealed, a specific atmosphere can be introduced and maintained. This allows for processes that require inert gases (like argon) to prevent oxidation or reactive gases to alter the surface chemistry of a part, such as in carburizing or nitriding on a small scale.

Key Heat Treating Applications Explained

While versatile, muffle furnaces excel at specific thermal processes where control is paramount.

Annealing and Stress Relief

Annealing is a process that softens metals, increases their ductility, and refines their grain structure. Muffle furnaces provide the slow, controlled cooling rates necessary for successful annealing, making parts easier to machine or form. Similarly, they are used for stress relief to remove internal stresses caused by prior manufacturing steps like welding or cold working.

Hardening and Quenching

Hardening involves heating a metal to a critical temperature and then rapidly cooling it (quenching) to lock in a hard, martensitic crystal structure. A muffle furnace provides the precise austenitizing temperature needed before the part is removed for quenching.

Sintering and Brazing

Sintering is a process used in powder metallurgy and additive manufacturing to bond particles together below their melting point. Brazing joins two or more metal items by melting a filler metal into the joint. In both cases, the clean, controlled environment of a muffle furnace prevents oxidation and ensures strong, reliable bonds.

Understanding the Trade-offs

While powerful, muffle furnaces are not a universal solution. Understanding their limitations is key to proper application.

Ideal for Small Batches and Components

The enclosed chamber design makes muffle furnaces perfectly suited for processing small, high-value components. This includes dental implants, biomedical devices, electronic components, and parts for aerospace sensors. They are also the standard for laboratory-scale material testing and R&D.

Not Suited for High-Volume Production

The batch-based nature and limited size of a muffle furnace make it inefficient for mass production. Industries processing thousands of parts per hour, like automotive fasteners, rely on continuous systems like belt or roller hearth furnaces.

Atmosphere Control Requires Additional Systems

While a muffle furnace enables atmosphere control, it does not inherently create it. Achieving a specific atmosphere requires an external system for gas supply, monitoring, and regulation, which adds to the setup's complexity and cost.

Making the Right Choice for Your Application

Selecting the right furnace depends entirely on your process requirements, material sensitivity, and production scale.

- If your primary focus is precision heat treatment of small, sensitive parts: A muffle furnace is the ideal choice for its uniformity and contamination-free environment.

- If your primary focus is R&D or new material qualification: The versatility and control offered by a muffle furnace make it an indispensable laboratory tool.

- If your primary focus is high-volume, continuous manufacturing: You should explore solutions like belt furnaces or continuous kilns designed for mass production.

Ultimately, choosing a muffle furnace is a decision for quality and control over sheer volume.

Summary Table:

| Application | Key Benefit | Ideal Use Cases |

|---|---|---|

| Annealing & Stress Relief | Uniform heating for controlled cooling | Softening metals, improving ductility |

| Hardening & Quenching | Precise temperature control before quenching | Achieving hard martensitic structures |

| Sintering & Brazing | Contamination-free environment for strong bonds | Powder metallurgy, additive manufacturing |

| Controlled Atmosphere Processes | Isolation for inert or reactive gases | Preventing oxidation, surface treatments |

Need a reliable high-temperature furnace for your lab or small-batch production? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced solutions like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements for contamination-free, precise heat treatment. Contact us today to enhance your processes with tailored furnace solutions!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure

- What metals cannot be heated by induction? Understanding Material Suitability for Efficient Heating