Selecting the right muffle furnace is a critical decision that directly impacts the accuracy, safety, and efficiency of your laboratory or production processes. The choice hinges on aligning key technical specifications—primarily your required temperature range, chamber size, and control precision—with the specific demands of your intended application.

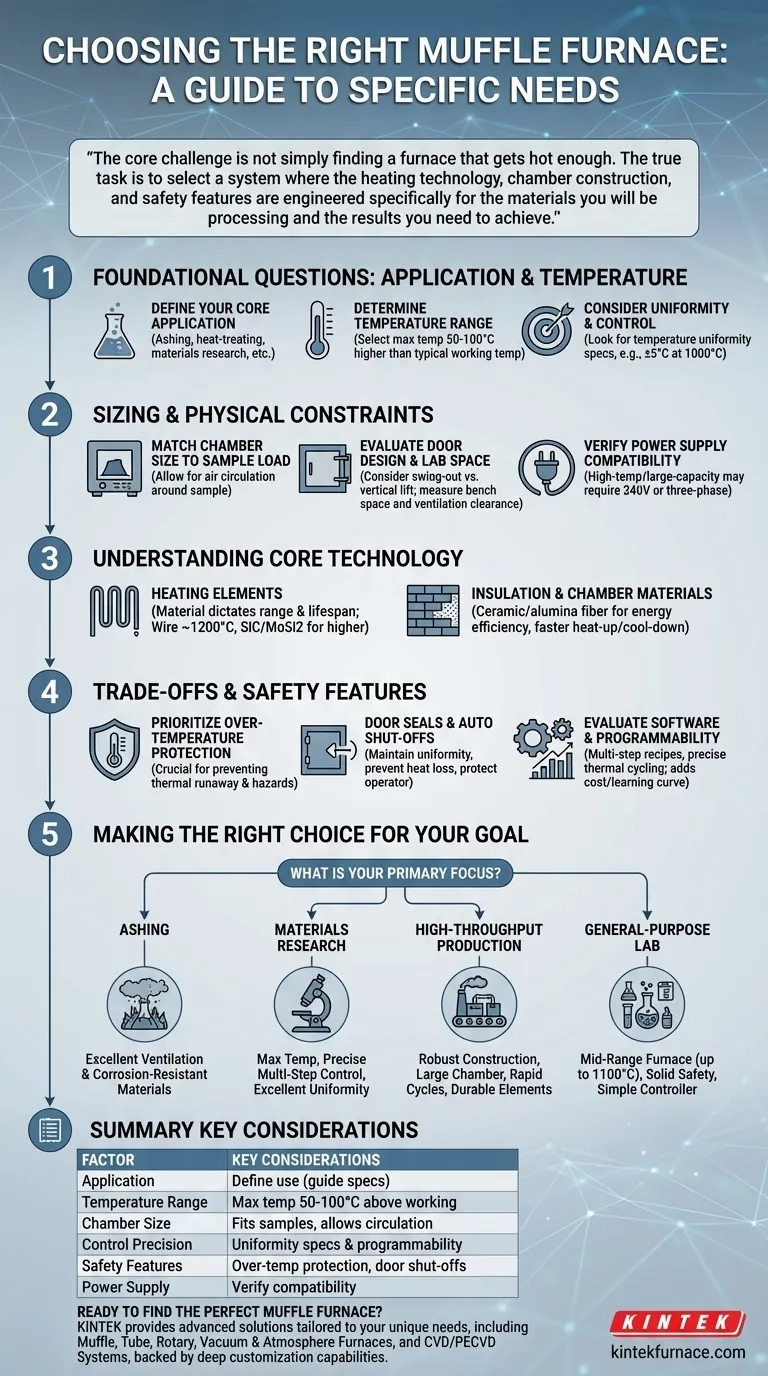

The core challenge is not simply finding a furnace that gets hot enough. The true task is to select a system where the heating technology, chamber construction, and safety features are engineered specifically for the materials you will be processing and the results you need to achieve.

The Foundational Questions: Application and Temperature

Before evaluating any specific model, you must first define the fundamental parameters of your work. These initial answers will narrow your options significantly.

Define Your Core Application

Your intended use is the most important factor. A furnace designed for ashing organic materials has different requirements than one used for hardening steel.

Common applications include ashing, heat-treating, materials research, brazing, alloying, and ceramics firing. Each process places unique demands on the furnace, such as the need for specific atmospheric conditions or resistance to corrosive byproducts.

Determine Your Required Temperature Range

A furnace's maximum operating temperature is its headline feature, but you must consider both the peak and the working temperature.

Consistently running a furnace at its absolute maximum temperature can shorten the life of its heating elements. A good rule of thumb is to select a model with a maximum temperature at least 50-100°C higher than your typical working temperature.

Consider Temperature Uniformity and Control

For many scientific and industrial processes, precision is paramount. It’s not enough for the furnace to reach a setpoint; it must maintain that temperature evenly throughout the entire chamber.

Look for specifications on temperature uniformity (e.g., ±5°C at 1000°C). This ensures that a sample placed in the corner of the chamber is treated identically to one in the center. The quality of the temperature controller and its software dictates this precision.

Sizing and Physical Constraints

The physical reality of the furnace and your lab space introduces practical limitations that are easy to overlook.

Match Chamber Size to Your Sample Load

The internal chamber dimensions must accommodate your largest sample or the total batch size you intend to process.

Consider not just the sample itself, but also the crucible or container holding it. Always allow for adequate air circulation around the sample for uniform heating, meaning the chamber should be significantly larger than the sample volume.

Evaluate Door Design and Lab Space

Furnaces come with different door configurations, most commonly a swing-out door or a vertical lift door. A lift door can act as a safety shield for the operator while loading hot samples.

Measure your available bench space carefully. Remember to account for the clearance needed to fully open the furnace door and for proper ventilation around the unit's exterior.

Verify Power Supply Compatibility

High-temperature and large-capacity furnaces are power-intensive. They may require a 240V or even a three-phase power supply, which may not be standard in all labs. Confirming your facility’s electrical capabilities beforehand prevents costly installation surprises.

Understanding the Core Technology

The internal components of the furnace determine its performance, durability, and long-term cost of ownership.

The Role of Heating Elements

Heating elements are the heart of the furnace and are a primary consumable. Their material dictates the furnace's temperature range and lifespan.

Common wire elements are suitable for temperatures up to around 1200°C. For higher temperatures, furnaces use more robust and expensive elements made of silicon carbide (SiC) or molybdenum disilicide (MoSi2).

Insulation and Chamber Materials

The furnace's insulation directly impacts its energy efficiency and exterior surface temperature. Modern furnaces use rigid, lightweight ceramic or alumina fiber insulation.

This high-quality insulation allows for faster heat-up and cool-down times and ensures the exterior remains safe to touch, protecting both personnel and nearby equipment.

Understanding the Trade-offs and Safety Features

A furnace is a powerful piece of equipment, and its safety and operational features are non-negotiable. Understanding the trade-offs is key to avoiding common pitfalls.

Prioritize Over-Temperature Protection

This is the single most important safety feature. An independent over-temperature protection circuit will shut down the furnace if the main controller fails, preventing a catastrophic thermal runaway that could destroy the furnace, your samples, and create a serious fire hazard.

The Importance of Door Seals and Auto Shut-offs

A well-designed door seal is critical for maintaining temperature uniformity and preventing heat loss. Many furnaces also include a door safety switch that automatically cuts power to the heating elements when the door is opened, protecting the operator from direct heat exposure.

Evaluate Software and Programmability

Basic furnaces may only allow for a single setpoint. More advanced models feature programmable controllers that can store multi-step recipes, allowing you to automatically ramp temperature up, hold it for a specific duration (a "soak"), and cool it down at a controlled rate.

While more complex, this programmability is essential for materials science, ceramics, and any process requiring precise thermal cycling. However, it adds cost and a steeper learning curve.

Making the Right Choice for Your Goal

Your final decision should be a balanced assessment of capability, safety, and budget, all guided by your primary application.

- If your primary focus is routine ashing: Prioritize a furnace with excellent ventilation and corrosion-resistant chamber materials to handle the byproducts of combustion.

- If your primary focus is materials research: Prioritize maximum temperature capability, precise multi-step programmable control, and excellent temperature uniformity.

- If your primary focus is high-throughput production: Emphasize robust construction, a large chamber, rapid heating cycles, and long-term durability of the heating elements.

- If your primary focus is general-purpose lab use: A mid-range furnace (up to 1100°C) with solid safety features and a simple controller offers the best balance of versatility and cost.

By systematically matching the furnace's capabilities to your process needs, you can invest confidently in a tool that will deliver reliable and accurate results for years to come.

Summary Table:

| Factor | Key Considerations |

|---|---|

| Application | Define use (e.g., ashing, materials research) to guide specs |

| Temperature Range | Choose max temp 50-100°C above working temp for longevity |

| Chamber Size | Ensure it fits samples and allows air circulation |

| Control Precision | Look for uniformity specs (e.g., ±5°C) and programmability |

| Safety Features | Prioritize over-temperature protection and door auto shut-offs |

| Power Supply | Verify compatibility with lab electrical systems |

Ready to find the perfect muffle furnace for your lab? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your unique needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities. Whether you're in materials research, production, or general lab work, we ensure precise temperature control, safety, and efficiency. Contact us today to discuss how our furnaces can optimize your processes and deliver reliable results!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis