At its core, a muffle furnace works by indirect heating. It uses electric heating elements to heat an insulated outer chamber, which then radiates heat uniformly into a separate inner chamber—the "muffle"—where the sample is placed. This design isolates the sample from the heating elements and any potential contaminants, ensuring a clean and precisely controlled high-temperature environment.

The defining principle is not just about generating heat, but about creating an isolated and clean heating environment. The "muffle" is a physical barrier that separates the material being heated from the direct energy source, preventing contamination and ensuring temperature uniformity.

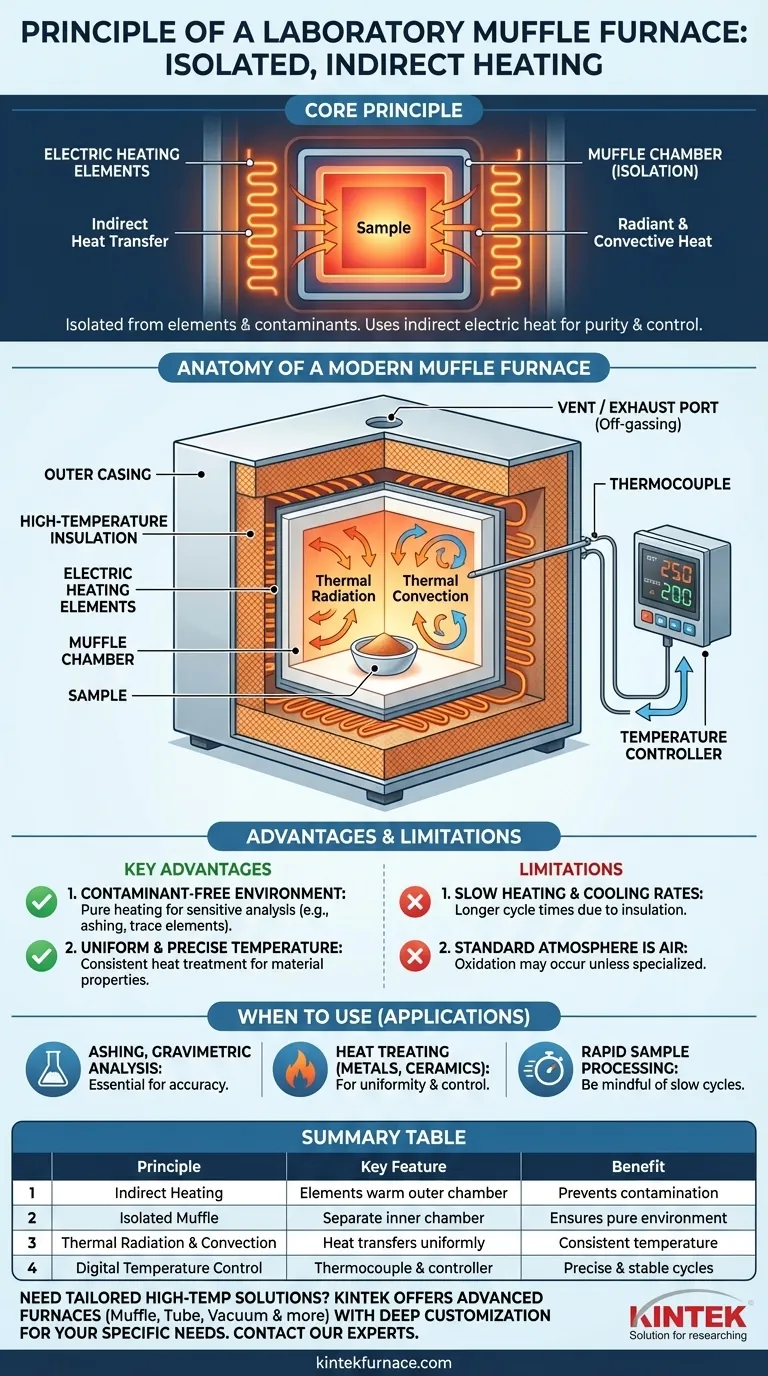

The Core Principle: Isolated, Indirect Heating

A muffle furnace's design is elegantly simple and focused on one primary goal: purity. Unlike a conventional oven or a direct-flame furnace, every component is engineered to protect the integrity of the sample.

The 'Muffle' Chamber

The "muffle" itself is the heart of the furnace. It is an inner chamber, typically made of high-temperature ceramic, that contains the sample.

Its purpose is to act as a barrier. It isolates the sample from the electrical heating elements, preventing any potential interaction or contamination.

Electric Heating Elements

Modern laboratory muffle furnaces are electric. High-resistance wires or rods (made of materials like nichrome or silicon carbide) are embedded within the furnace's walls, outside the muffle chamber.

When electricity flows through these elements, they heat up intensely due to electrical resistance. They do not burn fuel, so there are no combustion byproducts like soot or gases to contaminate the sample.

Heat Transfer Mechanisms

The heat generated by the elements must travel into the muffle chamber to reach the sample. This occurs through two primary physical processes.

- Thermal Radiation: The hot inner walls of the furnace radiate heat energy directly to the sample, similar to how the sun warms the earth. This is the dominant form of heat transfer at very high temperatures.

- Thermal Convection: The air inside the chamber heats up, becomes less dense, and circulates. This movement of hot air helps distribute the temperature evenly throughout the muffle.

This dual mechanism ensures the sample is heated uniformly from all sides, avoiding hot spots.

Anatomy of a Modern Muffle Furnace

Beyond the core principle, a few key components work together to ensure reliable and precise operation.

High-Temperature Insulation

The entire heating assembly is encased in thick layers of ceramic fiber or refractory brick insulation. This material is critical for minimizing heat loss, which allows the furnace to reach and maintain very high temperatures (often over 1000°C) efficiently and safely.

The Thermocouple

A thermocouple is a temperature sensor that extends into the heating chamber. It continuously measures the internal temperature with high accuracy.

The Temperature Controller

The thermocouple sends its reading to a digital temperature controller. This controller compares the actual temperature to the user's setpoint.

If the temperature is too low, the controller sends power to the heating elements. If it's too high, it cuts the power. This constant feedback loop maintains the desired temperature with remarkable stability.

Vents and Exhaust Ports

Most muffle furnaces include a small port or vent. This allows moisture or fumes released from the sample during heating (a process called off-gassing) to escape, preventing pressure buildup and maintaining a consistent internal atmosphere.

Understanding the Trade-offs

While powerful, a muffle furnace is a specialized tool with specific advantages and limitations.

Key Advantage: A Contaminant-Free Environment

This is the primary reason to use a muffle furnace. For sensitive applications like ashing (burning off organic material to measure inorganic content) or trace element analysis, any contamination from a fuel source would ruin the results. The muffle's isolation guarantees purity.

Key Advantage: Uniform and Precise Temperature

The combination of robust insulation, indirect heating, and a digital controller delivers exceptional temperature stability and uniformity. This is vital for materials science, where precise heat treatments determine a material's final properties.

Limitation: Heating and Cooling Rates

The same heavy insulation that holds heat so well also makes the furnace slow to heat up and, especially, slow to cool down. A cycle can take several hours, which must be factored into any laboratory workflow.

Limitation: Standard Atmosphere is Air

Unless specifically designed as a vacuum or inert gas furnace, a standard muffle furnace operates in air. The heating process can still cause oxidation, which may be undesirable for certain materials.

How to Apply This to Your Project

Your choice to use a muffle furnace should be driven by the specific requirements of your work.

- If your primary focus is ashing, gravimetric analysis, or trace metal testing: The muffle furnace is non-negotiable, as its clean heating environment is essential for accurate results.

- If your primary focus is heat treating metals, ceramics, or glass: The furnace's excellent temperature uniformity and precise control are its most valuable features.

- If your primary focus is rapid sample processing: Be mindful that the slow heating and cooling cycles of a muffle furnace can be a significant bottleneck in your workflow.

Ultimately, the muffle furnace is the definitive tool for any application demanding pure, uniform, and precisely controlled heat.

Summary Table:

| Principle | Key Feature | Benefit |

|---|---|---|

| Indirect Heating | Heating elements warm an outer chamber | Prevents sample contamination |

| Isolated Muffle | Separate inner chamber holds the sample | Ensures a pure heating environment |

| Thermal Radiation & Convection | Heat transfers uniformly from all sides | Provides consistent temperature for accurate results |

| Digital Temperature Control | Thermocouple and controller maintain setpoint | Delivers precise and stable heating cycles |

Need a high-temperature furnace solution tailored to your lab's unique requirements?

At KINTEK, we leverage our exceptional R&D and in-house manufacturing capabilities to provide advanced, high-performance furnace solutions. Whether your work involves precise ashing, materials heat treatment, or any application demanding a contaminant-free environment, our product line—including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems—is designed for reliability and accuracy.

Our strong deep customization capability ensures we can precisely adapt a furnace to meet your specific experimental needs. Let us help you achieve superior results with equipment built for purity and precision.

Contact our experts today to discuss your project and discover the perfect KINTEK furnace for your laboratory.

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the primary function of a muffle furnace in iron-modified activated carbon prep? Optimize Adsorption Sites

- What is the function of a muffle furnace during 500°C pre-calcination? Master CeZrPAl Support Synthesis

- How does the use of a 100-mesh sieve contribute to the performance consistency of magnetic chitosan carbon?

- What is the purpose of heating a precursor solution to 80 °C and 300 rpm stirring? Achieve High-Entropy Uniformity

- What is the function of a muffle furnace in SiCf/Al-Mg pretreatment? Optimize Fiber Bonding with Thermal De-sizing