In the world of glassmaking, muffle furnaces are not just for generating heat; they are for creating a highly controlled environment. Their essential role is to enable critical thermal processes like melting, annealing, and surface finishing, where precise temperature control and a clean, contaminant-free atmosphere are paramount to achieving glass with exceptional clarity and structural integrity.

While many furnaces can reach high temperatures, a muffle furnace's primary value in glassmaking is its ability to deliver exceptionally clean and uniform heat. This controlled environment is non-negotiable for producing glass with high clarity, consistent properties, and freedom from internal stress.

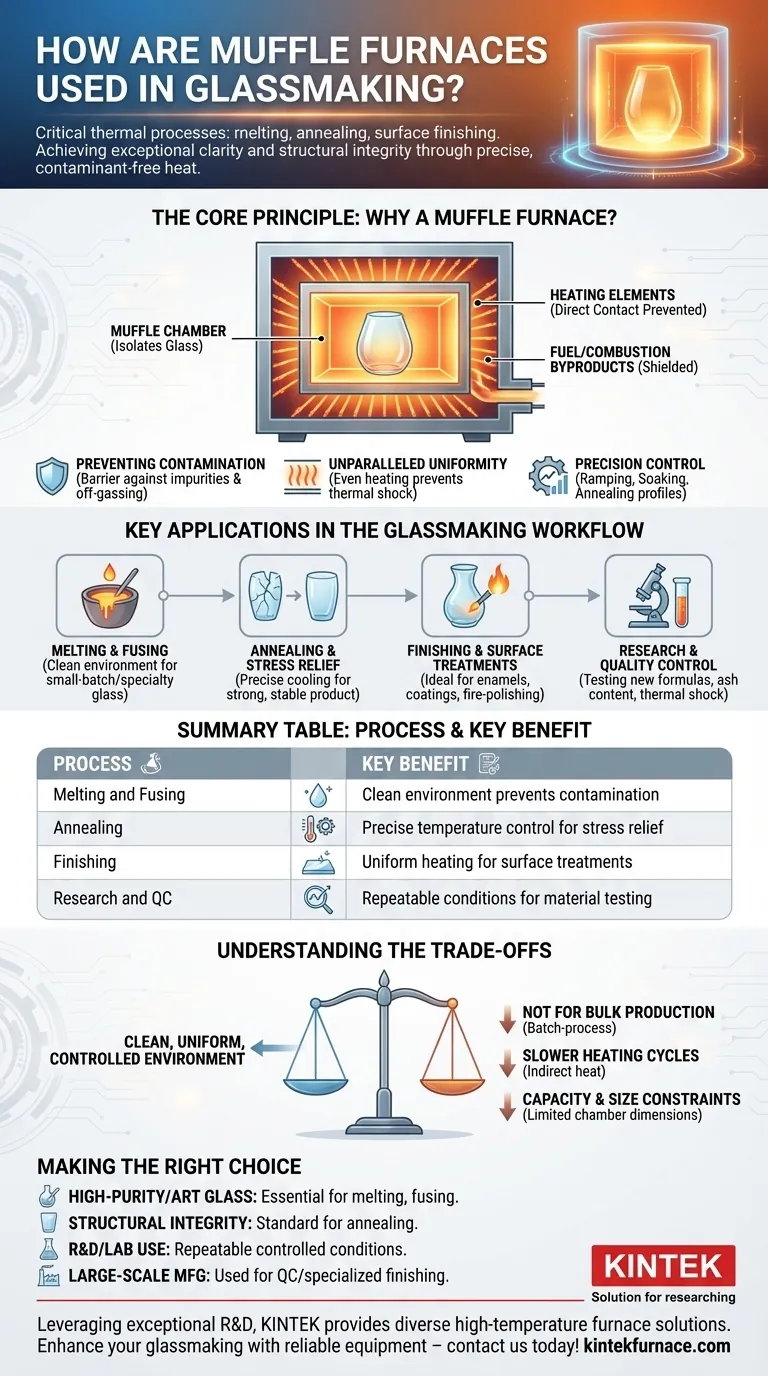

The Core Principle: Why a Muffle Furnace?

The name "muffle" reveals its function. The furnace contains an inner chamber (the muffle) that isolates the glass from direct contact with the heating elements or flames. This separation is the source of its key advantages.

Preventing Contamination

The muffle acts as a physical barrier. In fuel-fired furnaces, it shields the glass from combustion byproducts. In electric furnaces, it prevents any potential off-gassing or particles from the heating elements from embedding in the glass surface. This is critical for producing optical-grade or high-purity glass.

Unparalleled Temperature Uniformity

The muffle heats up and radiates energy evenly onto the workpiece from all sides. This uniform heating is crucial for preventing thermal shock and internal stresses, which can cause glass to become brittle or crack during or after processing.

Precision Control for Complex Cycles

Glass requires specific heating and cooling rates, a process known as ramping (heating up), soaking (holding a temperature), and annealing (cooling down). Muffle furnaces, with their advanced insulation and digital controllers, excel at executing these precise thermal profiles automatically.

Key Applications in the Glassmaking Workflow

A muffle furnace is used at several critical stages, from creation to finishing, especially in artistic, custom, and research-oriented glasswork.

Melting and Fusing

For small-batch or specialty glass production, a muffle furnace provides the clean environment needed to melt raw materials (like sand, soda ash, and lime) or fuse pieces of glass (cullet) together without introducing impurities. This is common in art glass studios and R&D labs.

Annealing and Stress Relief

This is arguably the most critical application. After glass is blown, cast, or shaped, it cools unevenly, creating immense internal stress. Annealing is the process of reheating the glass to a specific temperature and then cooling it down very slowly. A muffle furnace's ability to execute a precise, hands-off cooling curve makes it the industry standard for this task, ensuring a strong, stable final product.

Finishing and Surface Treatments

The furnace's controlled environment is ideal for secondary processes. This includes firing on decorative enamels, applying coatings, or heat-treating the glass to alter its surface properties. Processes like slumping (shaping glass over a mold) and fire-polishing also benefit from this precise heat.

Research and Quality Control

In materials science, laboratories use muffle furnaces to develop and test new glass formulas. They are also used for quality control tests, such as determining the ash content or thermal shock resistance of a particular glass composition.

Understanding the Trade-offs

While indispensable, muffle furnaces are not the solution for every glassmaking scenario. Understanding their limitations provides a complete picture.

Not Ideal for Bulk Production

For high-volume manufacturing of items like bottles or window panes, massive, continuous-melt tanks and long annealing ovens (called lehrs) are more efficient. Muffle furnaces are batch-process tools, best suited for custom work, R&D, and smaller-scale operations.

Slower Heating Cycles

Because the heat is indirect (it must first heat the muffle, which then radiates to the glass), the heating process can be slower compared to a direct-fire furnace. This is the trade-off made for a cleaner, more uniform environment.

Capacity and Size Constraints

The size of the object you can process is limited by the internal dimensions of the muffle chamber. This makes them unsuitable for very large architectural or sculptural pieces, which require custom-built kilns.

Making the Right Choice for Your Goal

The decision to use a muffle furnace depends entirely on the desired outcome and scale of your work.

- If your primary focus is producing high-purity, custom, or art glass: The clean, controlled environment of a muffle furnace is essential for melting, fusing, and shaping.

- If your primary focus is ensuring the structural integrity of any glass piece: A muffle furnace is the standard for executing the precise annealing cycles required to remove internal stresses.

- If your primary focus is research and development of new glass formulas: A laboratory muffle furnace provides the repeatable, controlled conditions necessary for accurate material testing.

- If your primary focus is large-scale industrial manufacturing: Muffle furnaces are used for quality control and specialized finishing, but the primary melting is handled by larger, continuous industrial furnaces.

Ultimately, mastering the use of a muffle furnace is key to controlling the fundamental properties that define high-quality glass.

Summary Table:

| Process | Key Benefit |

|---|---|

| Melting and Fusing | Clean environment prevents contamination |

| Annealing | Precise temperature control for stress relief |

| Finishing | Uniform heating for surface treatments |

| Research and QC | Repeatable conditions for material testing |

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Enhance your glassmaking processes with our reliable equipment—contact us today to discuss how we can support your specific needs!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the primary function of a muffle furnace in iron-modified activated carbon prep? Optimize Adsorption Sites

- How does the use of a 100-mesh sieve contribute to the performance consistency of magnetic chitosan carbon?

- What is the core role of a muffle furnace in the synthesis of calcium oxide from eggshells? Achieve High-Purity CaO

- What is the purpose of heating a precursor solution to 80 °C and 300 rpm stirring? Achieve High-Entropy Uniformity

- Why is re-calcination in a muffle furnace necessary for photocatalysts? Restore Efficiency via Thermal Oxidation