At their core, box furnaces are categorized into two primary types based on their power source. The vast majority of modern box furnaces are electric, leveraging resistive heating elements, while a smaller subset of specialized, often larger industrial units are gas-fueled.

The choice between an electric and gas-fired box furnace is a fundamental decision that hinges on your priorities. You are essentially choosing between the high precision, cleanliness, and control of electric power versus the potential for lower operating costs at a massive scale offered by gas.

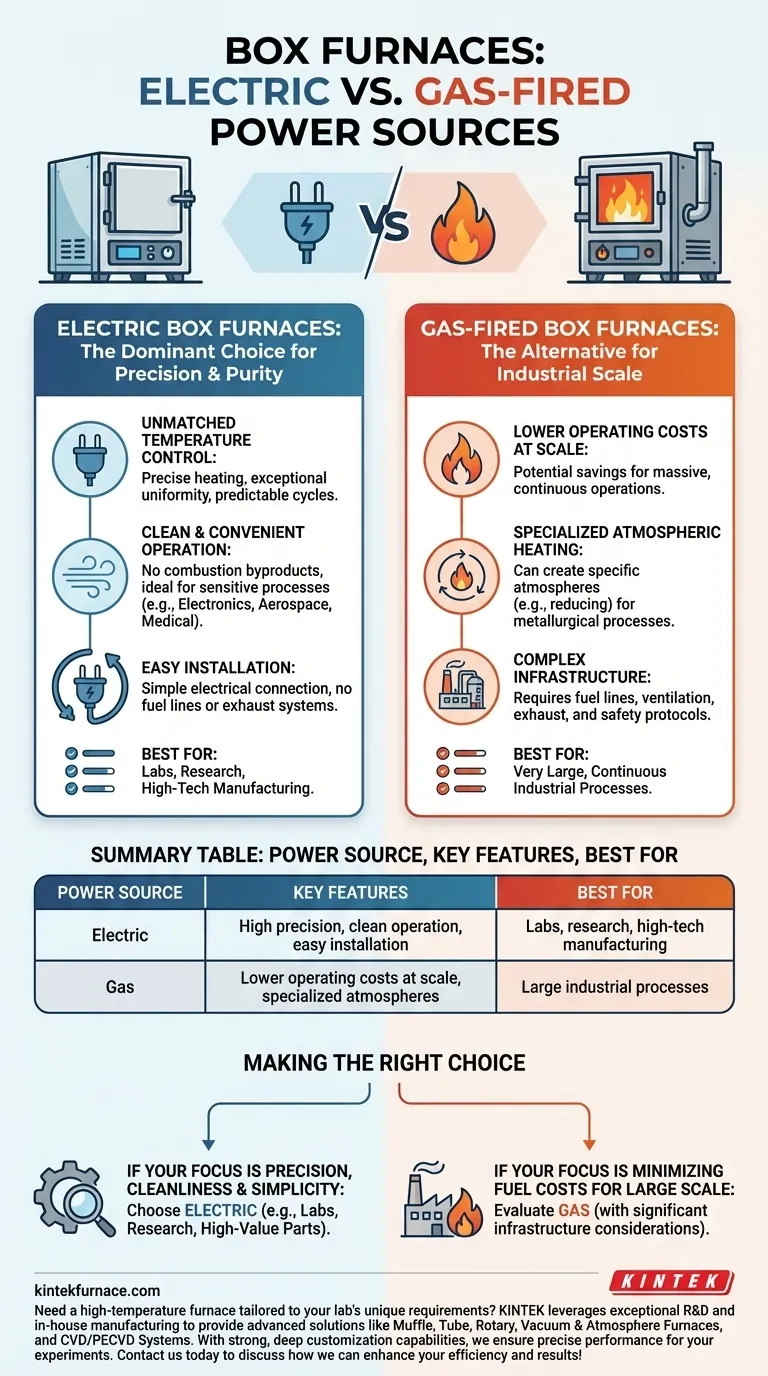

The Dominant Choice: Electric Box Furnaces

Electric models represent the default standard for most laboratory, research, and production applications due to their inherent advantages in control and simplicity.

Unmatched Temperature Control

The primary advantage of electric furnaces is precision. Electric heating elements can be managed with sophisticated controllers to achieve exceptional temperature uniformity throughout the chamber.

This allows for precise heating ramps, controlled soaking periods, and predictable cooling cycles, which are critical for sensitive processes.

Clean and Convenient Operation

Electric furnaces produce no combustion byproducts. This makes them ideal for applications where atmospheric purity is essential, such as in electronics, aerospace, and medical device manufacturing.

Their operation is also straightforward. They require only a suitable electrical connection, eliminating the need for fuel lines, exhaust flues, and complex combustion safety systems. This simplifies installation and maintenance significantly.

The Alternative: Gas-Fired Box Furnaces

While far less common, gas-fueled box furnaces fill a niche in specific large-scale industrial scenarios where their unique characteristics provide an advantage.

The Scale and Operating Cost Argument

The main driver for choosing a gas-fired furnace is often operating cost at a very large scale. For massive, continuous heat-treating operations, the cost of natural gas per unit of energy (BTU) can be substantially lower than electricity.

This economic benefit typically only applies to very large furnaces running for extended periods, where the fuel savings can offset the higher initial cost and complexity of the system.

Specialized Atmospheric Heating

Direct-fired gas furnaces, where the combustion products enter the heating chamber, can naturally create a specific type of atmosphere. This can be intentionally leveraged in certain metallurgical processes that benefit from a reducing atmosphere created by the products of combustion.

Understanding the Trade-offs

Choosing a power source is not just about preference; it involves clear engineering and operational trade-offs that directly impact your results and facility.

Precision vs. Raw Power

Electric furnaces offer surgical precision, which is non-negotiable for research and high-tech manufacturing. Gas-fired systems provide immense heating power efficiently but lack the fine-tuned control and uniformity inherent to electric models.

Installation and Infrastructure

An electric furnace is a relatively "plug-and-play" piece of equipment. In contrast, a gas furnace is a complex installation requiring dedicated fuel lines, ventilation and exhaust systems, and rigorous safety protocols for handling combustible fuel.

Environmental and Safety Factors

Electric furnaces are clean, quiet, and produce no direct emissions, making them suitable for almost any indoor environment. Gas furnaces produce noise and exhaust gases (like CO, CO2, and NOx) that must be safely managed, and they carry the inherent risks associated with handling flammable fuels.

Making the Right Choice for Your Application

Your final decision must align directly with the primary goal of your heating process and the realities of your facility.

- If your primary focus is precision, cleanliness, and operational simplicity (e.g., labs, research, materials testing, or high-value parts): An electric box furnace is the clear and correct choice.

- If your primary focus is minimizing fuel costs for a very large, continuous industrial process where pinpoint precision is secondary: It is worth evaluating a gas-fired furnace, but only after carefully considering the significant infrastructure and safety requirements.

Ultimately, selecting the right power source ensures your furnace is a capable tool, not a source of process variability or operational complexity.

Summary Table:

| Power Source | Key Features | Best For |

|---|---|---|

| Electric | High precision, clean operation, easy installation | Labs, research, high-tech manufacturing |

| Gas | Lower operating costs at scale, specialized atmospheres | Large industrial processes |

Need a high-temperature furnace tailored to your lab's unique requirements? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced solutions like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. With strong deep customization capabilities, we ensure precise performance for your experiments. Contact us today to discuss how we can enhance your efficiency and results!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide

- How is a Vertical Tube Furnace used for fuel dust ignition studies? Model Industrial Combustion with Precision