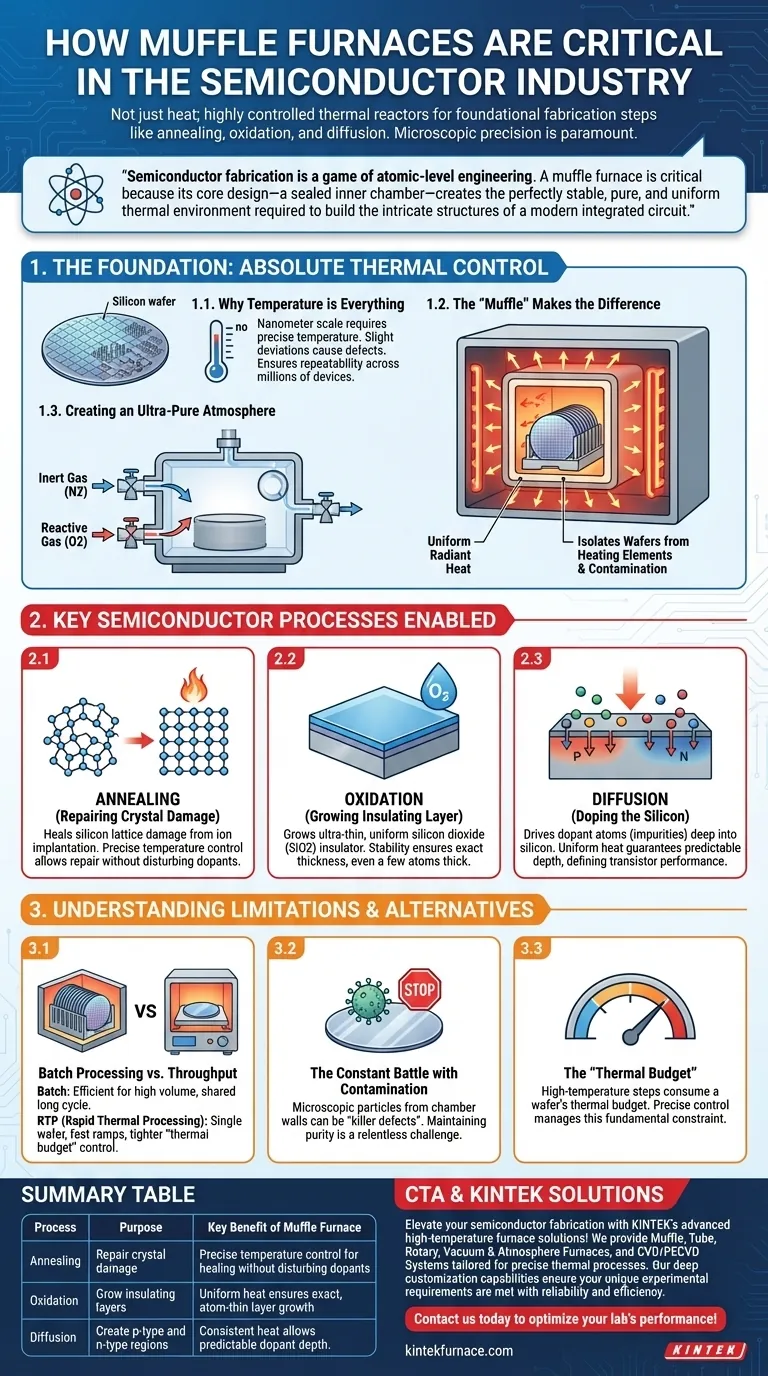

In the semiconductor industry, a muffle furnace is not just a source of heat; it is a highly controlled thermal reactor. These furnaces are essential for foundational fabrication steps like annealing, oxidation, and diffusion, where microscopic precision is paramount. Their ability to deliver exceptionally uniform temperature in a contamination-free, controlled atmosphere is what makes the creation of reliable, high-performance microchips possible.

Semiconductor fabrication is a game of atomic-level engineering. A muffle furnace is critical because its core design—a sealed inner chamber—creates the perfectly stable, pure, and uniform thermal environment required to build the intricate structures of a modern integrated circuit.

The Foundation of Chip Making: Absolute Thermal Control

Why Temperature is Everything

The transistors and pathways on a microchip are measured in nanometers. At this scale, even a slight deviation in temperature across a silicon wafer can cause defects, altering electrical properties and rendering entire batches of chips useless.

Semiconductor manufacturing demands repeatability across millions or billions of devices. The stable, predictable environment of a muffle furnace ensures that every wafer in a batch, and every batch that follows, is processed under identical conditions.

The "Muffle" Makes the Difference

The defining feature of a muffle furnace is the "muffle" itself—a separate inner chamber that isolates the semiconductor wafers from the raw heating elements.

Think of it like baking a delicate soufflé in a covered ceramic dish placed inside a larger oven. The dish protects the soufflé from the direct, harsh heat of the heating coils, allowing it to cook gently and evenly.

This design provides two critical advantages: it prevents contamination from the heating elements and ensures radiant heat is distributed with extreme uniformity.

Creating an Ultra-Pure Atmosphere

The sealed muffle chamber allows operators to control the chemical environment with precision. Air can be pumped out to create a vacuum, or the chamber can be filled with specific gases.

For many processes, an inert gas like nitrogen is used to prevent the silicon from reacting with oxygen. For others, like oxidation, a controlled amount of pure oxygen is intentionally introduced. This atmospheric control is impossible with a simple open-element oven.

Key Semiconductor Processes Enabled by Muffle Furnaces

Annealing: Repairing Crystal Damage

Processes like ion implantation, which embed dopant atoms into the silicon, physically damage its perfect crystalline structure.

Annealing is a carefully controlled heating and cooling process that "heals" the silicon lattice. The precise temperature control of a muffle furnace allows this repair to happen without disturbing the placement of the newly implanted dopants.

Oxidation: Growing the Insulating Layer

Transistors require an ultra-thin, perfectly uniform layer of silicon dioxide (a type of glass) to act as a critical insulator.

During oxidation, wafers are heated to over 1000°C inside a muffle furnace in an environment of pure oxygen. The furnace's stability ensures this insulating layer grows to the exact required thickness, which can be just a few atoms thick.

Diffusion: Doping the Silicon

Diffusion is a process that uses high heat to drive dopant atoms (impurities) from the wafer's surface deep into the silicon. This is how the fundamental positive (p-type) and negative (n-type) regions that form a transistor are created.

The uniform heat of the muffle furnace guarantees that these dopants diffuse to the correct, predictable depth across the entire wafer, defining the transistor's ultimate performance.

Understanding the Limitations and Alternatives

Batch Processing vs. Throughput

Traditional muffle furnaces are batch tools, processing a large cassette of wafers (25 or more) at once. While this is efficient for established processes, it means all wafers share the same long heating and cooling cycle.

For newer, more sensitive steps, the industry often uses Rapid Thermal Processing (RTP) systems that process one wafer at a time with very fast temperature ramps, offering tighter control over the "thermal budget."

The Constant Battle with Contamination

While the muffle isolates wafers from the heating elements, any microscopic particle shed from the chamber walls can land on a wafer and become a "killer defect," ruining a chip.

Maintaining the absolute purity of the furnace chamber is a relentless and expensive operational challenge.

The "Thermal Budget"

Every high-temperature step consumes a portion of a wafer's "thermal budget." Too much time at high temperature can cause previously created structures, like dopant profiles, to shift or blur.

The precise control of a muffle furnace is critical for managing this budget, but it is a fundamental constraint in the overall fabrication sequence.

Making the Right Choice for Your Process

The decision to use a muffle furnace versus a more modern alternative depends entirely on the fabrication step's specific requirements.

- If your primary focus is high-volume, foundational layers: A batch muffle furnace remains the industry standard for processes like growing thick oxide layers or long annealing cycles, where stability and throughput are key.

- If your primary focus is ultra-shallow, sensitive junctions: A single-wafer Rapid Thermal Processing (RTP) system is often preferred to minimize the thermal budget and achieve faster cycle times.

- If your primary focus is creating a specific chemical film: The controlled atmosphere of a furnace (often a Low-Pressure Chemical Vapor Deposition variant) is essential for growing films that require specific precursor gases.

Ultimately, the muffle furnace provides the bedrock of thermal stability and purity upon which the complex, multi-layered world of semiconductor devices is built.

Summary Table:

| Process | Purpose | Key Benefit of Muffle Furnace |

|---|---|---|

| Annealing | Repair crystal damage from ion implantation | Precise temperature control for healing without disturbing dopants |

| Oxidation | Grow insulating silicon dioxide layers | Uniform heat ensures exact, atom-thin layer growth |

| Diffusion | Create p-type and n-type regions in silicon | Consistent heat allows predictable dopant depth across wafers |

Elevate your semiconductor fabrication with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems tailored for precise thermal processes like annealing and oxidation. Our deep customization capabilities ensure your unique experimental requirements are met with reliability and efficiency. Contact us today to discuss how our solutions can optimize your lab's performance and yield!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the function of a muffle furnace in SiCf/Al-Mg pretreatment? Optimize Fiber Bonding with Thermal De-sizing

- What is the function of a muffle furnace during 500°C pre-calcination? Master CeZrPAl Support Synthesis

- What is the purpose of heating a precursor solution to 80 °C and 300 rpm stirring? Achieve High-Entropy Uniformity

- What is the core role of a muffle furnace in the synthesis of calcium oxide from eggshells? Achieve High-Purity CaO

- Why is re-calcination in a muffle furnace necessary for photocatalysts? Restore Efficiency via Thermal Oxidation