At its core, a muffle furnace is indispensable for modern quality control because it provides a highly controlled and uncontaminated high-temperature environment. This allows manufacturers and researchers to perform destructive testing, verify material composition, and simulate extreme conditions, ensuring a product’s integrity, safety, and compliance with industry standards before it ever reaches the customer.

The true value of a muffle furnace in quality control is not just its ability to get hot, but its power to reveal a material's breaking point. It acts as a gatekeeper, identifying potential weaknesses and defects under controlled thermal stress, thereby safeguarding product reliability and performance.

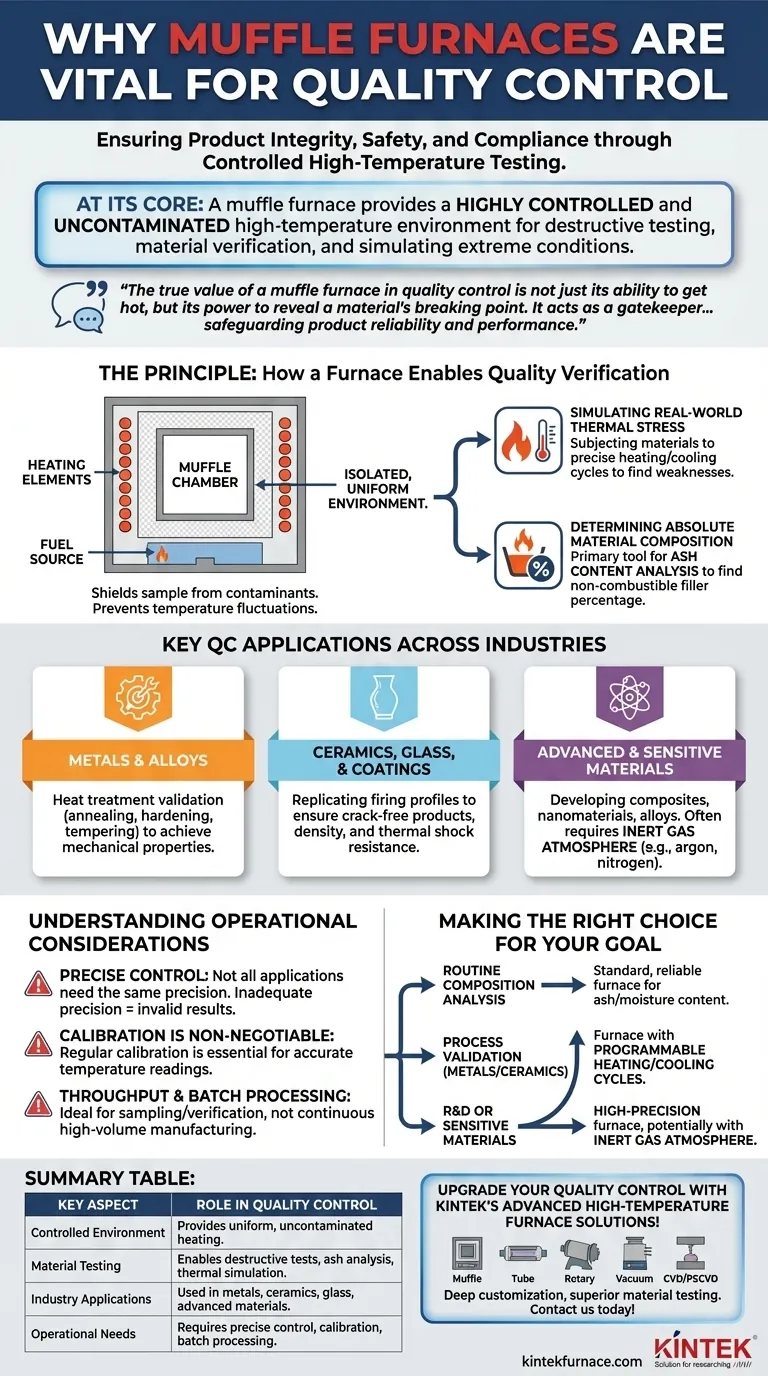

The Principle: How a Furnace Enables Quality Verification

A muffle furnace is more than just a high-temperature oven. Its design is fundamental to its role in quality control. The term "muffle" refers to the insulated inner chamber that separates the material sample from the heating elements.

Creating an Isolated, Uniform Environment

The muffle ensures that heating is indirect and uniform, preventing temperature fluctuations that could compromise a test. More importantly, it shields the sample from any contaminants produced by the fuel or electrical heating elements, guaranteeing that the analysis reflects the material’s intrinsic properties.

Simulating Real-World Thermal Stress

Quality control labs use muffle furnaces to simulate the harshest thermal conditions a product might encounter during its operational life. By subjecting materials like glass, metal, or ceramics to precise heating and cooling cycles, engineers can identify potential weaknesses or defects long before they become a liability in the field.

Determining Absolute Material Composition

Many quality standards depend on knowing the exact composition of a material. A muffle furnace is the primary tool for ash content analysis, where a sample is burned at a high temperature to determine the percentage of non-combustible filler or inorganic material. This is a critical quality metric for everything from polymers and foods to pharmaceuticals.

Key QC Applications Across Industries

The ability to control heat with precision makes the muffle furnace a versatile tool for ensuring quality in a wide range of sectors.

Metals and Alloys

In metallurgy, heat treatment processes like annealing, hardening, and tempering are used to achieve specific mechanical properties such as strength and ductility. A muffle furnace validates that these treatments are performed correctly and that the final metal product meets engineering specifications.

Ceramics, Glass, and Coatings

For technical ceramics and glass, the firing cycle is everything. A muffle furnace allows QC technicians to test samples by replicating production firing profiles to ensure the final product is free from cracks, has the correct density, and will withstand thermal shock.

Advanced and Sensitive Materials

Modern materials science relies on muffle furnaces for developing and testing composites, nanomaterials, and alloys. Some advanced models can operate with an inert gas atmosphere (like argon or nitrogen), which is essential for heat-treating materials that oxidize or react when exposed to air.

Understanding the Operational Considerations

While powerful, a muffle furnace is a precision instrument whose effectiveness depends on its proper use and selection.

The Importance of Precise Control

Not all applications have the same requirements. Routine ash testing may not need the same level of ramp-rate control as developing a new alloy. Using a furnace without adequate temperature precision for a sensitive task can lead to invalid results and poor quality outcomes.

Calibration is Non-Negotiable

An uncalibrated furnace provides misleading data. For quality control, where decisions are based on meeting specific temperature thresholds, regular calibration is essential. An inaccurate temperature reading can mean the difference between passing a faulty product or failing a good one.

Throughput and Batch Processing

Most muffle furnaces are designed for batch testing, not for a continuous production line. This makes them ideal for sampling and verification but means they are a checkpoint in the QC process rather than an integrated part of high-volume manufacturing itself.

Making the Right Choice for Your Goal

To leverage a muffle furnace effectively, align its capabilities with your primary quality control objective.

- If your primary focus is routine composition analysis: A standard, reliable furnace with stable temperature control is perfectly suited for common tests like determining ash or moisture content.

- If your primary focus is process validation for metals or ceramics: Prioritize a furnace with programmable heating and cooling cycles to accurately simulate your production processes.

- If your primary focus is R&D or testing sensitive materials: You will need a high-precision furnace, potentially with options for a controlled inert gas atmosphere to prevent oxidation.

Ultimately, integrating a muffle furnace into your quality control process provides the certainty that your materials will perform as promised.

Summary Table:

| Key Aspect | Role in Quality Control |

|---|---|

| Controlled Environment | Provides uniform, uncontaminated heating for accurate testing |

| Material Testing | Enables destructive tests, ash analysis, and thermal simulation |

| Industry Applications | Used in metals, ceramics, glass, and advanced materials for validation |

| Operational Needs | Requires precise temperature control, calibration, and batch processing |

Upgrade your quality control with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable tools like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs, helping you achieve superior material testing and compliance. Contact us today to discuss how our furnaces can enhance your lab's efficiency and reliability!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production