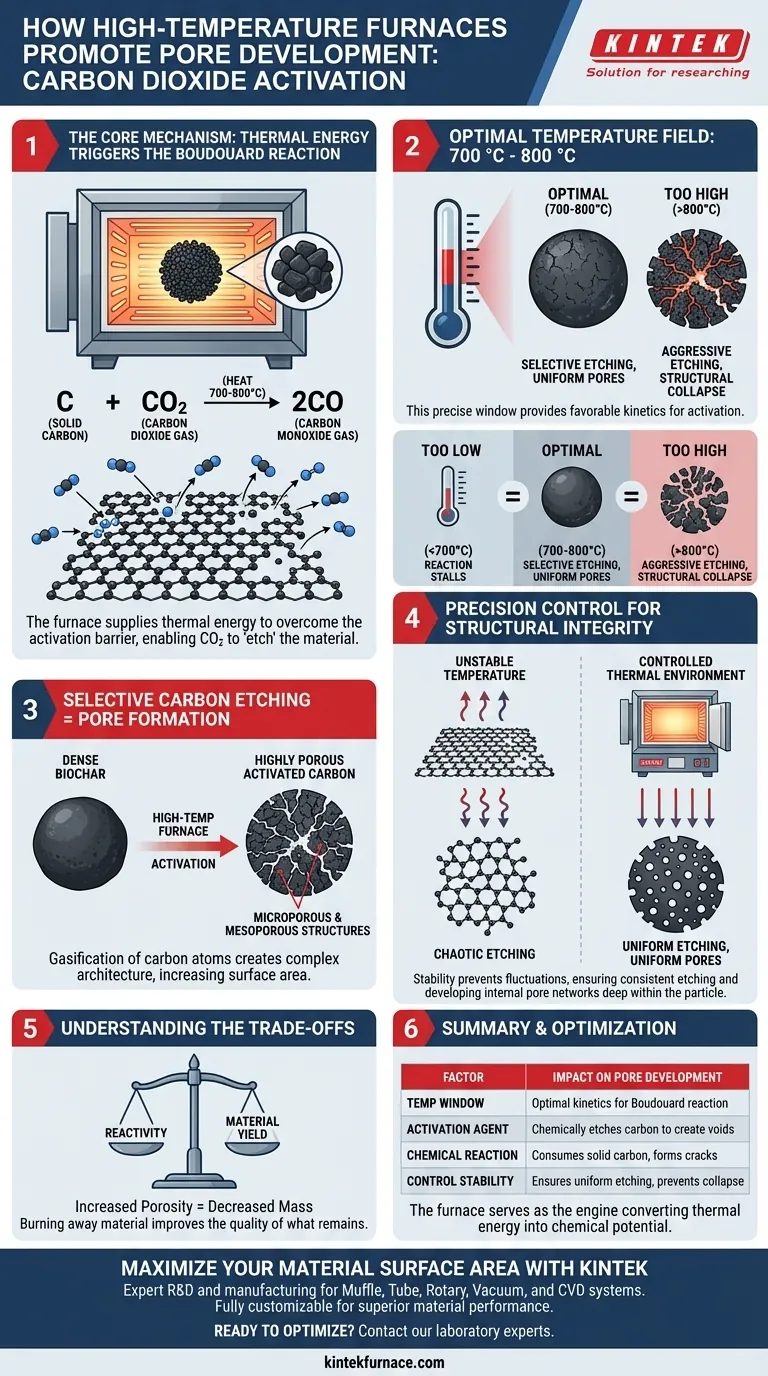

The temperature field provided by a High-Temperature Reaction Furnace promotes pore development by supplying the thermal energy required to trigger the Boudouard reaction. Specifically, by maintaining a temperature between 700 °C and 800 °C, the furnace enables carbon dioxide molecules to chemically attack the biochar surface. This reaction consumes solid carbon atoms, effectively "etching" the material to create a network of internal voids.

Core Insight: The furnace does not simply heat the material; it creates a specific kinetic environment where carbon dioxide acts as an activation agent. By selectively gasifying carbon atoms into carbon monoxide, the thermal field physically carves out complex cracks and channels, transforming dense biochar into highly porous activated carbon.

The Mechanism of Thermal Activation

The Critical Role of the Boudouard Reaction

The primary driver of pore creation during carbon dioxide activation is the Boudouard reaction.

This is a thermodynamic process where carbon dioxide (CO2) reacts with solid carbon (C) to form carbon monoxide (2CO). However, this reaction is not spontaneous at low temperatures; it requires a high-energy environment to overcome the activation barrier.

The Specific Temperature Window

The High-Temperature Reaction Furnace provides the necessary environment by sustaining a temperature field strictly between 700 °C and 800 °C.

It is within this precise thermal window that the reaction kinetics become favorable for activation. Without this specific heat intensity, the CO2 would remain inert relative to the carbon structure.

Selective Carbon Etching

At these elevated temperatures, a heterogeneous reaction occurs at the interface between the gas and the solid.

The CO2 molecules target and "consume" carbon atoms from the biochar's skeleton. This selective removal of mass acts as a chemical etching process.

Formation of Complex Architecture

As carbon atoms are converted into gas and released, they leave behind empty spaces.

This continuous etching process results in the formation of complex cracks, gaps, and channels. These voids constitute the increased surface area and porosity that define high-quality activated carbon.

The Importance of Precision Control

Ensuring Structural Integrity

While high heat is necessary, the stability of the temperature field is equally critical.

A high-temperature tube furnace provides a controlled thermal environment that prevents fluctuations. This precision ensures that the etching process is uniform throughout the material, rather than chaotic or localized.

Developing Pore Volume

The controlled thermal environment facilitates the creation of large volumes of microporous and mesoporous structures.

By maintaining a consistent temperature, the furnace ensures the reaction proceeds deep within the particle, rather than just on the exterior surface. This depth is required to fully develop the internal pore network.

Understanding the Trade-offs

Temperature Sensitivity

Operating outside the optimal 700 °C to 800 °C range creates significant performance risks.

If the temperature is too low, the Boudouard reaction will stall, resulting in biochar with virtually no activation. Conversely, if temperatures are uncontrolled or excessive, the aggressive etching may collapse the carbon skeleton entirely, destroying the pores you intended to create.

Reactivity vs. Yield

The process of activation is fundamentally a trade-off between surface area and material yield.

Because the furnace facilitates the consumption of carbon atoms to create holes, the total mass of the material decreases as porosity increases. You are essentially burning away a portion of your product to improve the quality of what remains.

Optimizing Your Activation Strategy

To achieve the best results with carbon dioxide activation, focus on the following parameters:

- If your primary focus is Pore Development: Ensure your furnace creates a sustained temperature field of at least 700 °C to drive the Boudouard reaction effectively.

- If your primary focus is Material Uniformity: Prioritize a furnace with precise thermal stability to ensure consistent etching across the entire carbon skeleton.

Ultimately, the furnace serves as the engine that converts thermal energy into chemical potential, allowing gas molecules to sculpt the internal architecture of the carbon.

Summary Table:

| Factor | Description | Impact on Pore Development |

|---|---|---|

| Temperature Window | 700 °C to 800 °C | Optimal kinetics for the Boudouard reaction |

| Activation Agent | Carbon Dioxide (CO2) | Chemically etches carbon to create internal voids |

| Chemical Reaction | C + CO2 → 2CO | Consumes solid carbon to form cracks and channels |

| Control Stability | High Precision | Ensures uniform etching and prevents structural collapse |

Maximize Your Material Surface Area with KINTEK

Are you struggling with inconsistent porosity or structural collapse during carbon activation? KINTEK's high-temperature reaction furnaces are engineered for the extreme precision required to master the Boudouard reaction.

Backed by expert R&D and manufacturing, we offer Muffle, Tube, Rotary, Vacuum, and CVD systems—all fully customizable to meet your specific thermal activation needs. Whether you are developing microporous structures for energy storage or mesoporous filters, our technology ensures a stable, uniform temperature field for superior material performance.

Ready to optimize your activation process? Contact our laboratory experts today to find the perfect furnace for your research or production line.

Visual Guide

References

- Sylwia Kukowska, Katarzyna Szewczuk‐Karpisz. New fruit waste-derived activated carbons of high adsorption performance towards metal, metalloid, and polymer species in multicomponent systems. DOI: 10.1038/s41598-025-85409-0

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- How does a forced-air drying oven contribute to the transformation of GaN precursor resins? Ensure Material Uniformity

- What are the advantages of directly adding heat carriers to oil sludge? Boost Efficiency & Preserve Resource Value

- What are the technical functions of carrier gases in VTD? Master Vapor Transport Deposition Control

- What long-term considerations are important when selecting a kiln? Ensure Cost-Effective, Compliant Operations

- What occurs during the recrystallization stage of annealing? Restore Ductility and Reset Microstructure

- How is a vacuum impregnation system utilized during wood leaching resistance tests? Achieve Full Saturation for EN 84

- What is the primary function of a laboratory electric drying oven in ACBP production? Ensure Precise Pre-treatment

- Why is HR-TEM used after high-temperature heat treatment? Visualize structural evolution and material integrity.