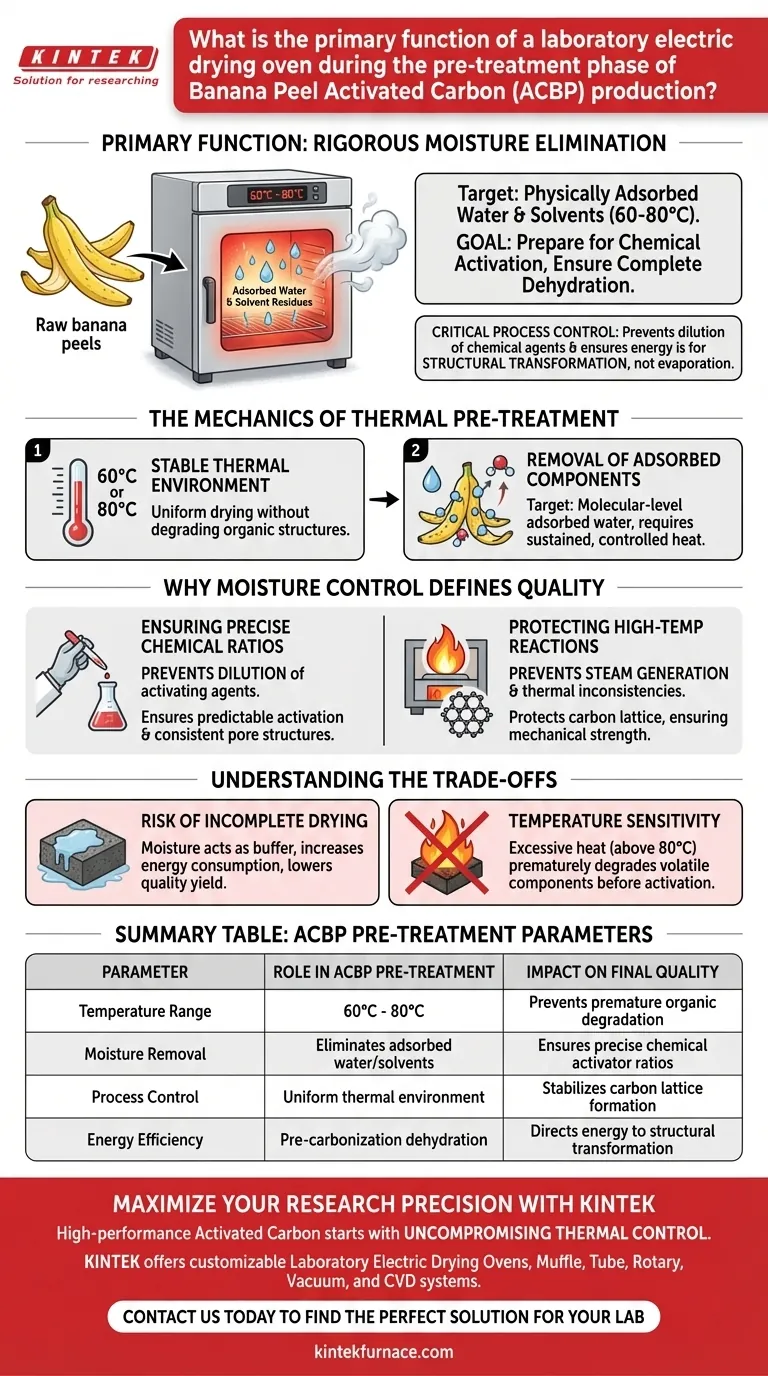

The primary function of a laboratory electric drying oven in the pre-treatment of Banana Peel Activated Carbon (ACBP) is to rigorously eliminate physically adsorbed water and solvent residues. Operating typically between 60°C and 80°C, this device prepares the raw material for chemical activation by ensuring it is completely dehydrated. This moisture removal is not merely about drying; it is a vital step to prevent water from interfering with the delicate chemical reactions that follow.

By stabilizing the raw material's moisture content, the drying oven acts as a critical process control. It prevents the dilution of chemical agents and ensures that energy during carbonization is used for structural transformation rather than water evaporation.

The Mechanics of Thermal Pre-treatment

Establishing a Stable Thermal Environment

The laboratory electric drying oven is designed to maintain a consistent temperature, generally set at 60°C or 80°C for this specific application.

This stability is crucial. It ensures that the banana peels are dried uniformly without degrading the organic structures required for carbon formation.

Removal of Adsorbed Components

The oven targets physically adsorbed water and any lingering solvents on the raw banana peels.

Unlike surface water, adsorbed water clings to the material at a molecular level. Removing it requires the sustained, controlled heat that only a specialized oven can provide.

Why Moisture Control Defines Quality

Ensuring Precise Chemical Ratios

The most critical reason for this drying phase is to facilitate precise acid-base ratios during the subsequent activation stage.

If the banana peels retain moisture, that water will dilute the chemical activating agents. This dilution alters the concentration of the activator, leading to unpredictable activation and inconsistent pore structures in the final carbon.

Protecting High-Temperature Reactions

Thorough drying prevents moisture from interfering with high-temperature carbonization.

If water remains in the precursor material, it can cause uncontrolled steam generation or thermal inconsistencies inside the furnace. This disrupts the formation of the carbon lattice, reducing the mechanical strength and adsorptive capacity of the ACBP.

Understanding the Trade-offs

The Risk of Incomplete Drying

Failing to achieve complete dryness creates a chain reaction of inefficiency.

Moisture acts as a buffer, absorbing thermal energy intended for carbonization. This results in higher energy consumption and a lower yield of high-quality activated carbon.

Temperature Sensitivity

While drying is essential, excessive heat during this pre-treatment phase can be detrimental.

Temperatures must be kept within the recommended range (e.g., 60–80°C). Exceeding this can prematurely degrade the volatile components of the banana peel before the controlled carbonization phase begins, essentially "burning" the material before it is activated.

Optimizing Your ACBP Production Workflow

To ensure the highest quality Activated Carbon from banana peels, align your drying parameters with your specific production goals:

- If your primary focus is Chemical Efficiency: Ensure the material is bone-dry to prevent the dilution of expensive activating agents, maximizing their potency.

- If your primary focus is Structural Integrity: strictly monitor the oven temperature to remove moisture without damaging the organic precursor matrix.

A disciplined drying phase is the invisible foundation that transforms organic waste into a high-performance industrial sorbent.

Summary Table:

| Parameter | Role in ACBP Pre-treatment | Impact on Final Quality |

|---|---|---|

| Temperature Range | 60°C - 80°C | Prevents premature organic degradation |

| Moisture Removal | Eliminates adsorbed water/solvents | Ensures precise chemical activator ratios |

| Process Control | Uniform thermal environment | Stabilizes carbon lattice formation |

| Energy Efficiency | Pre-carbonization dehydration | Directs energy to structural transformation |

Maximize Your Research Precision with KINTEK

High-performance Activated Carbon starts with uncompromising thermal control. Backed by expert R&D and manufacturing, KINTEK offers a comprehensive suite of Muffle, Tube, Rotary, Vacuum, and CVD systems, alongside specialized laboratory electric drying ovens—all customizable for your unique material processing needs.

Whether you are optimizing banana peel activation or developing advanced industrial sorbents, our equipment ensures the thermal stability and moisture control required for superior results. Contact us today to find the perfect solution for your lab!

Visual Guide

References

- Nokuthula Mekgoe, Kriveshini Pillay. Synergistic electrochemical detection of ciprofloxacin using bismuth vanadate nanocomposite-modified activated carbon derived from banana peel biomass. DOI: 10.1039/d5ma00168d

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Small Rotary Kiln Calciner

- 1200℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Kiln for Pyrolysis Plant Heating

People Also Ask

- How does a stable constant temperature environment influence the structural development of LDHs during aging?

- What role does a laboratory blast drying oven play in the preparation of Ti-doped Mn3O4? Optimize Your Precursor Quality

- Why must raw kaolin undergo heat treatment for DLP 3D printing? Control Viscosity for Precision Printing

- What role do constant temperature water baths or ovens play in the sol-gel process for carbon aerogels? Master Kinetics

- Why is SF6 gas utilized as the primary inhibitor in AS-ALD on ZrO2? Master Defect-Based Passivation Strategy

- How do surface states affect lithium carbonate crystal morphology? Controlling Nucleation for Superior Particle Shape

- Why is immediate water-quenching required after thermal simulation? Preserve (CoCrNi)94Al3Ti3 Alloy Microstructure

- What role does a high-power graphite resistance furnace play in SiC ceramic treatment? Achieve Perfect Crystallization