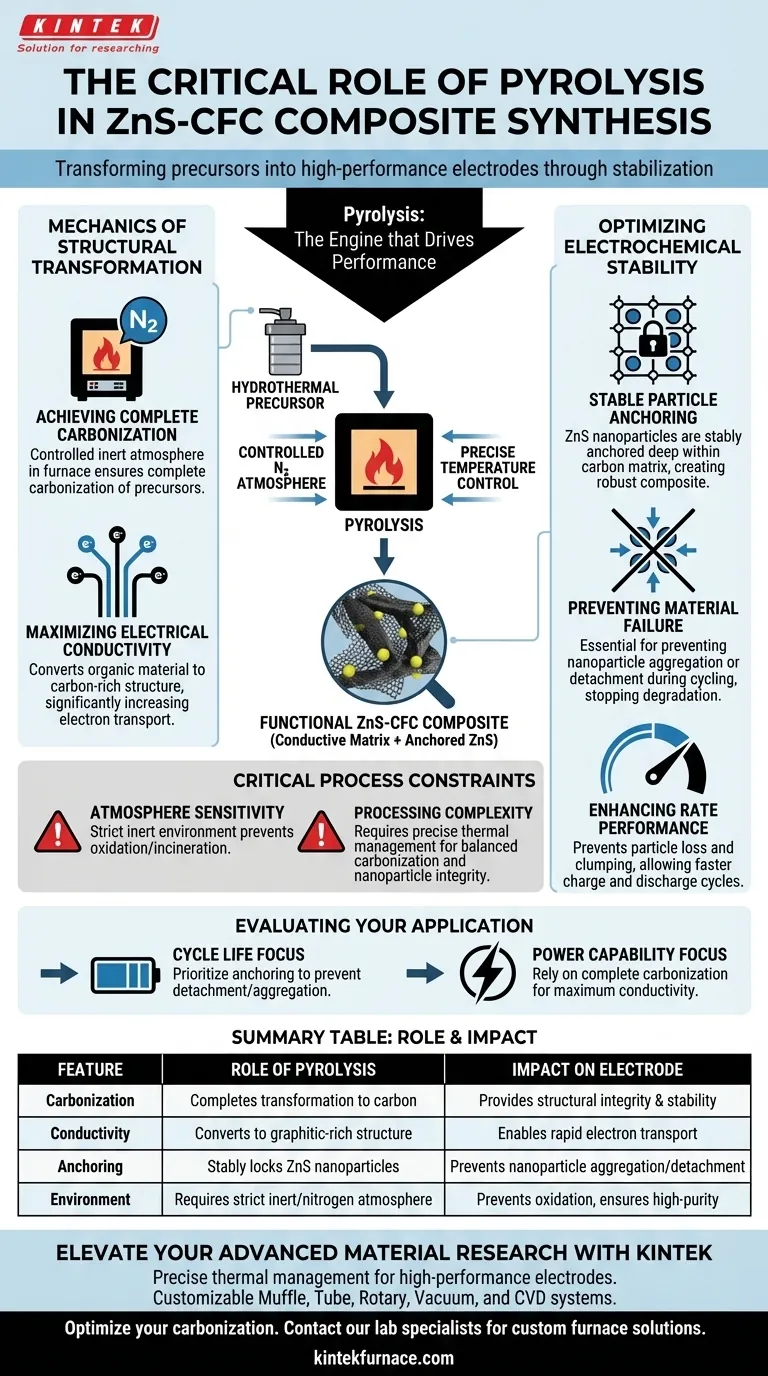

The subsequent pyrolysis step serves as the critical stabilization phase in the preparation of chicken feather-derived zinc sulfide-carbon fiber (ZnS-CFC) composites. While hydrothermal pretreatment initiates the reaction, pyrolysis transforms the precursor into a functional electrode by finalizing carbonization and locking active nanoparticles into a conductive matrix.

While the initial hydrothermal step shapes the material, pyrolysis is the engine that drives performance. It ensures high electrical conductivity and prevents structural degradation, making the final composite viable for rigorous electrochemical use.

The Mechanics of Structural Transformation

Achieving Complete Carbonization

The hydrothermal pretreatment is only a preliminary stage. To create a viable composite, the material must undergo pyrolysis in a furnace with a controlled nitrogen or inert atmosphere. This is the only way to achieve complete carbonization of the precursors.

Maximizing Electrical Conductivity

Organic precursors typically suffer from poor electron transport. The intense heat of pyrolysis converts these materials into a carbon-rich structure, which significantly increases the electrical conductivity of the composite. High conductivity is a non-negotiable requirement for efficient electrode performance.

Optimizing Electrochemical Stability

Stable Particle Anchoring

Conductivity alone is not enough; the active materials must remain in place. Pyrolysis ensures that zinc sulfide (ZnS) nanoparticles are stably anchored deep within the carbon matrix. This physical integration creates a robust composite rather than a loose mixture of parts.

Preventing Material Failure

Without the stabilizing effect of pyrolysis, nanoparticles act unpredictably under stress. The anchoring process is essential to prevent nanoparticles from aggregating or detaching during electrochemical cycling. This prevents the rapid degradation of the electrode's active surface area.

Enhancing Rate Performance

The stability provided by pyrolysis directly impacts the electrode's efficiency. By preventing particle loss and clumping, the process enhances the rate performance of the electrode, allowing it to handle faster charge and discharge cycles effectively.

Critical Process Constraints

Atmosphere Sensitivity

The success of this step hinges on maintaining a strict inert environment. Any failure to control the nitrogen atmosphere can lead to oxidation, which would incinerate the carbon matrix rather than graphitize it.

Processing Complexity

Unlike simple drying, pyrolysis adds a layer of complexity regarding thermal management. It requires precise temperature control to balance the carbonization of the fibers without compromising the integrity of the zinc sulfide nanoparticles.

Evaluating the Process for Your Application

When optimizing the preparation of ZnS-CFC composites, consider how pyrolysis aligns with your specific performance metrics.

- If your primary focus is cycle life: Prioritize the anchoring effect of pyrolysis to prevent nanoparticle detachment and aggregation over time.

- If your primary focus is power capability: Rely on the complete carbonization aspect to maximize electrical conductivity and rate performance.

By treating pyrolysis as a foundational requirement rather than an optional finish, you ensure the creation of a durable, highly conductive electrode material.

Summary Table:

| Feature | Role of Pyrolysis in ZnS-CFC Composites | Impact on Electrode Performance |

|---|---|---|

| Carbonization | Completes transformation of organic precursors into carbon | Provides structural integrity and chemical stability |

| Conductivity | Converts precursors into a graphitic-rich structure | Enables rapid electron transport for faster charging |

| Anchoring | Stably locks ZnS nanoparticles into the carbon matrix | Prevents nanoparticle aggregation and detachment |

| Environment | Requires strict inert/nitrogen atmosphere in furnace | Prevents oxidation and ensures high-purity carbon output |

Elevate Your Advanced Material Research with KINTEK

Precise thermal management is the difference between a failing precursor and a high-performance electrode. KINTEK provides the specialized equipment needed to master the pyrolysis phase. Backed by expert R&D and manufacturing, we offer customizable Muffle, Tube, Rotary, Vacuum, and CVD systems designed to maintain the strict inert atmospheres and temperature precision required for advanced carbon composite synthesis.

Ready to optimize your carbonization process? Contact our laboratory specialists today to find your custom furnace solution.

Visual Guide

References

- Perseverance Dzikunu, Pedro Vilaça. Waste-to-carbon-based supercapacitors for renewable energy storage: progress and future perspectives. DOI: 10.1007/s40243-024-00285-4

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Small Rotary Kiln Calciner

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

- Vacuum Heat Treat Sintering and Brazing Furnace

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

People Also Ask

- Why is it necessary to preheat casting molds to 300°C? Expert Thermal Control for Recycled Aluminum Alloy Production

- Why is argon particularly attractive for industrial applications? Unlock Cost-Effective Purity and Stability

- How does microstructural observation assist in optimizing LATP sintering? Master High-Density Material Processing

- What is the function of a sintering aid reservoir? Unlock Rapid Densification via MV-Sintering Technology

- What are the primary functions of high-purity nitrogen flow in carbon pyrolysis? Optimize Purity and Pore Structure

- What is the primary purpose of using a laboratory constant temperature drying oven for fuel sample preparation?

- What is the function of a drying oven in the post-treatment process of Ni and Zn-doped MgO nanoparticles?

- What are the main types of furnaces used in foundries for metal casting? Choose the Best for Your Metal