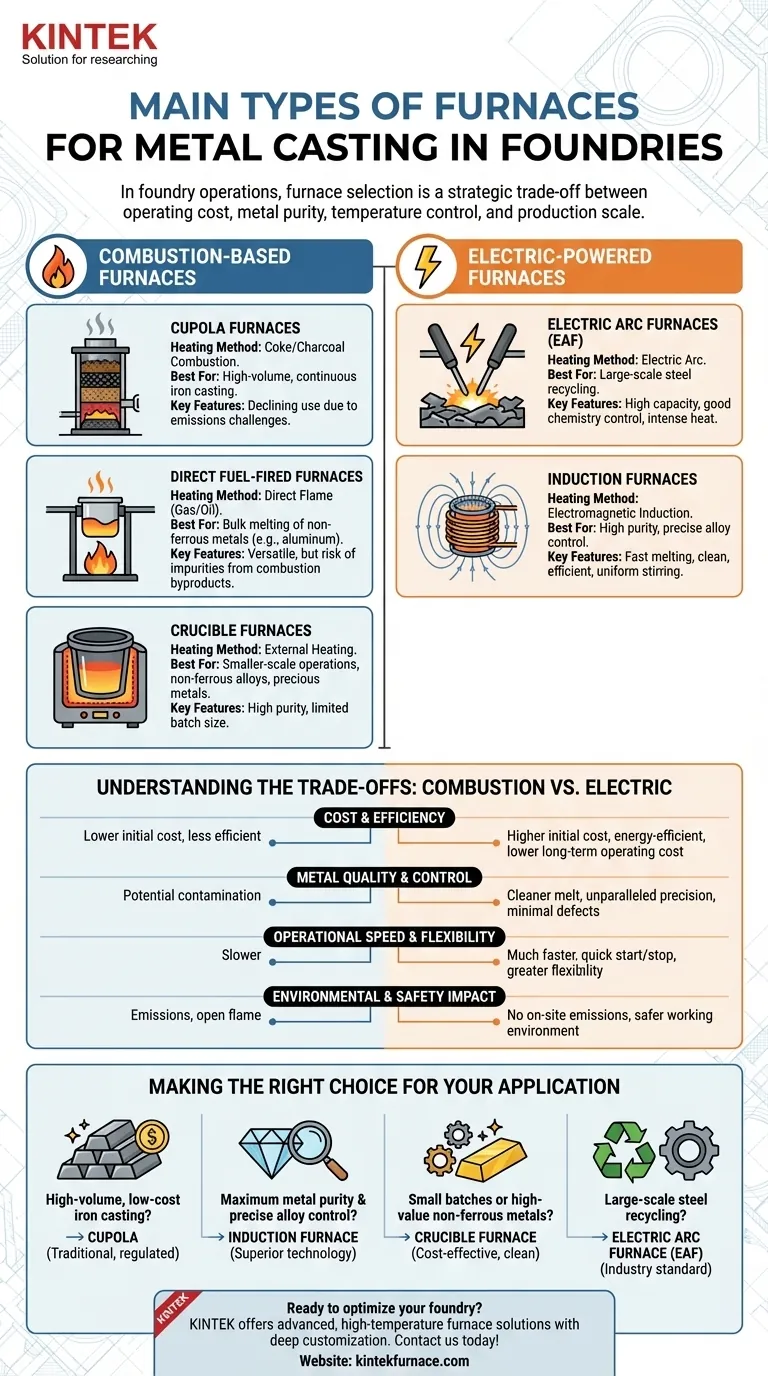

In foundry operations, the primary types of furnaces used for metal casting are cupolas, direct fuel-fired furnaces, crucible furnaces, electric arc furnaces, and induction furnaces. Each of these technologies uses a different method of heating—from direct combustion of fuel to advanced electromagnetic induction—and is selected based on the specific metal being cast, the required production volume, and the desired quality of the final product.

The central decision in choosing a foundry furnace is not about finding a single "best" option, but about matching the technology to your operational goals. The choice is a strategic trade-off between operating cost, metal purity, temperature control, and production scale.

Combustion-Based Furnaces

Combustion furnaces represent the traditional approach to melting metal, relying on the burning of fuel to generate heat. While often simpler in design, they come with specific operational characteristics.

Cupola Furnaces

Cupolas are tall, cylindrical furnaces that have historically been the workhorse for melting iron. They operate by burning coke and charcoal, which are layered with scrap iron and limestone.

These are best suited for very high-volume, continuous production of cast iron. However, their use has declined due to challenges in controlling emissions and metal chemistry precisely.

Direct Fuel-Fired Furnaces

These furnaces heat metal by exposing it directly to a flame generated by burning natural gas, oil, or propane. They are often used for bulk melting of non-ferrous metals like aluminum.

While versatile, direct contact with combustion byproducts can introduce impurities into the melt, potentially affecting the final alloy's properties.

Crucible Furnaces

In a crucible furnace, the metal is contained within a pot or crucible, which is then heated externally. This prevents direct contact between the metal and the heating fuel.

This method is ideal for smaller-scale operations, processing non-ferrous alloys, or working with precious metals where purity is paramount. The batch size is limited by the size of the crucible.

Electric-Powered Furnaces

Electric furnaces offer a more modern, controllable, and cleaner alternative to combustion. They leverage electrical energy to generate heat, providing significant advantages in quality and efficiency.

Electric Arc Furnaces (EAF)

An EAF melts metal by generating a massive electric arc between graphite electrodes and the metallic charge. The intense heat of the arc, which can exceed the temperature of the sun's surface, rapidly melts steel scrap.

This technology is the cornerstone of modern steel recycling, capable of melting enormous quantities of material with good-to-excellent chemistry control.

Induction Furnaces

Induction furnaces use electromagnetic induction to heat and melt metal without any direct contact. An alternating current is passed through a copper coil, creating a powerful magnetic field.

This field induces strong electrical "eddy" currents within the metal charge itself, and the metal's natural resistance to these currents generates intense, rapid heat from the inside out. This process also creates a natural stirring action, ensuring a highly uniform temperature and alloy composition.

Understanding the Trade-offs: Combustion vs. Electric

The choice between a traditional combustion furnace and a modern electric one involves balancing capital costs, operational efficiency, and final product quality.

Cost and Efficiency

Combustion furnaces may have a lower initial purchase price. However, electric induction furnaces are significantly more energy-efficient, converting a higher percentage of energy directly into useful heat. This leads to lower long-term operating costs and less wasted material.

Metal Quality and Control

Electric furnaces provide a much cleaner melt because there are no combustion byproducts to contaminate the metal. Induction furnaces offer unparalleled precision in temperature and alloy control, which is critical for producing high-performance castings with minimal defects.

Operational Speed and Flexibility

Induction furnaces melt metal much faster than most combustion methods and can be started and stopped quickly, offering greater operational flexibility. This makes them suitable for foundries that handle a variety of different metals or casting runs.

Environmental and Safety Impact

Electric furnaces produce no on-site emissions, contributing to a cleaner and safer working environment compared to fuel-fired systems. The absence of a large open flame in induction heating further enhances workplace safety.

Making the Right Choice for Your Application

Your choice of furnace should be driven by a clear understanding of your primary production goal.

- If your primary focus is high-volume, low-cost iron casting: A cupola is the traditional, though increasingly regulated, choice.

- If your primary focus is maximum metal purity and precise alloy control: An induction furnace is the superior technology.

- If your primary focus is small batches or high-value non-ferrous metals: A crucible furnace provides a cost-effective and clean solution.

- If your primary focus is large-scale steel recycling: An Electric Arc Furnace (EAF) is the industry standard.

Ultimately, the right furnace is the one that best aligns with your material, volume, quality, and cost objectives.

Summary Table:

| Furnace Type | Heating Method | Best For | Key Features |

|---|---|---|---|

| Cupola | Coke/Charcoal Combustion | High-volume iron casting | Continuous production, declining use due to emissions |

| Direct Fuel-Fired | Direct Flame (Gas/Oil) | Bulk non-ferrous metals | Versatile, risk of impurities |

| Crucible | External Heating | Small batches, precious metals | High purity, batch-limited |

| Electric Arc | Electric Arc | Steel recycling | High capacity, good chemistry control |

| Induction | Electromagnetic Induction | High purity, precise alloys | Fast melting, clean, efficient, uniform stirring |

Ready to optimize your foundry with the right furnace? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your needs. Our product line—including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems—is complemented by strong deep customization capabilities to precisely meet your unique experimental and production requirements. Whether you're focused on metal purity, cost efficiency, or scalability, we can help you achieve superior results. Contact us today to discuss how our furnaces can enhance your metal casting operations!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Induction Melting Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- How do vertical tube furnaces comply with environmental standards? A Guide to Clean, Efficient Operation

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents