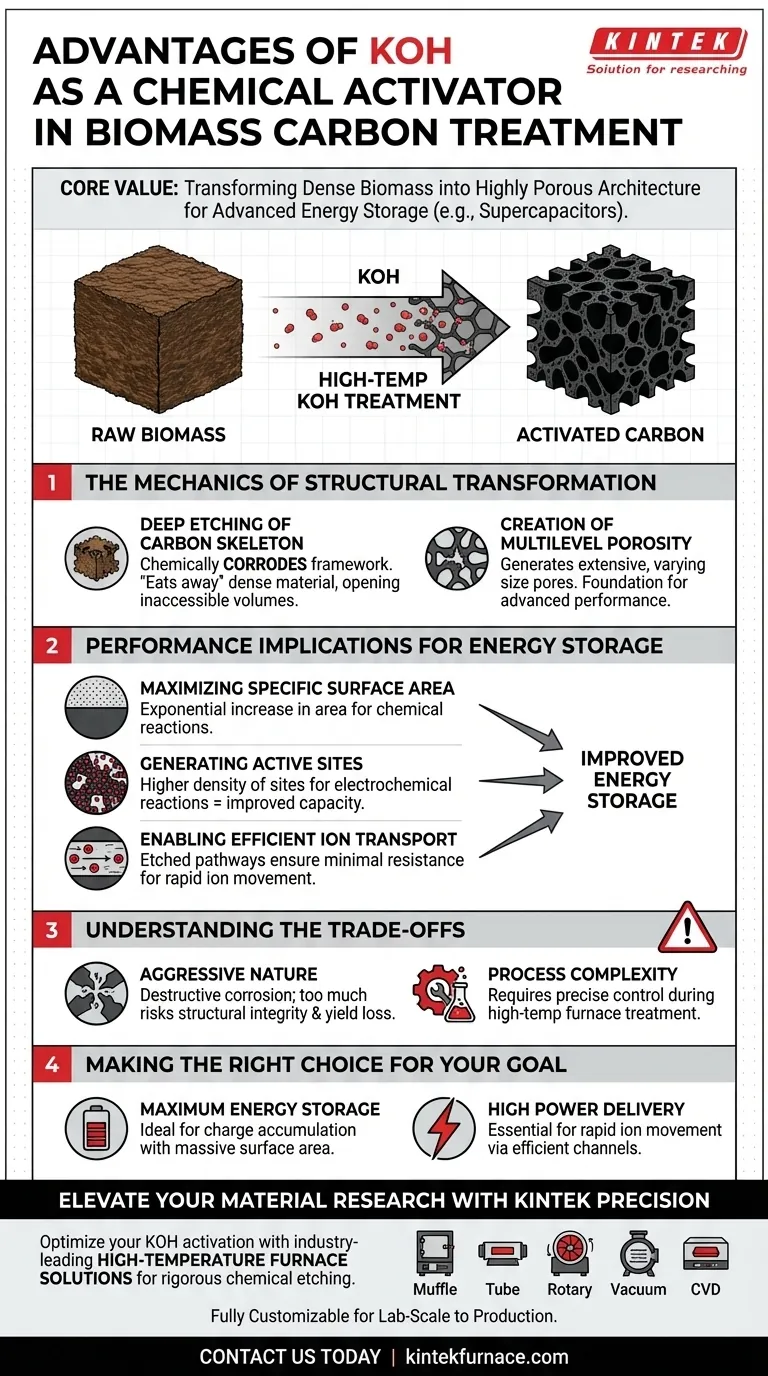

Potassium hydroxide (KOH) functions as a powerful chemical etching agent during the high-temperature treatment of biomass, fundamentally altering the material's physical structure. By actively corroding the carbon skeleton, KOH creates a complex, multilevel pore network that significantly amplifies the material's surface area and reactivity.

The core value of KOH activation is its ability to transform dense biomass into a highly porous architecture. This process is essential for creating the high-surface-area materials required for advanced energy storage devices like supercapacitors.

The Mechanics of Structural Transformation

Deep Etching of the Carbon Skeleton

At high temperatures, KOH does not merely coat the biomass; it chemically corrodes the carbon framework.

This aggressive reaction breaks down the dense carbon material. It effectively "eats away" at the structure to open up internal volumes that were previously inaccessible.

Creation of Multilevel Porosity

The corrosion process results in an extensive multilevel pore structure.

Rather than a uniform set of holes, KOH generates a hierarchical network of pores varying in size. This complex architecture is the foundation for advanced material performance.

Performance Implications for Energy Storage

Maximizing Specific Surface Area

The primary physical outcome of KOH activation is a significant increase in specific surface area.

By hollowing out the carbon skeleton, the total area available for chemical reactions increases exponentially. This is the defining characteristic that separates high-performance activated carbon from raw biomass char.

Generating Active Sites

With increased surface area comes a higher density of active sites.

These sites are the specific locations where electrochemical reactions occur. A higher number of active sites directly correlates to improved capacity in energy storage applications.

Enabling Efficient Ion Transport

The pore network created by KOH acts as a system of efficient transport channels.

In applications like supercapacitors, electrolyte ions must move quickly through the material. The etched pathways ensure that ions can traverse the carbon structure with minimal resistance.

Understanding the Trade-offs

The Aggressive Nature of Etching

While KOH is effective, it is important to recognize that it functions through destructive corrosion.

The process removes carbon mass to create pores. If the activation is too aggressive, it risks destroying the carbon skeleton entirely, leading to a loss of structural integrity and material yield.

Process Complexity

Using a strong chemical agent like KOH requires careful handling during the high-temperature furnace treatment.

The corrosive nature of the reaction demands precise control to ensure the pore structure is developed without compromising the material's mechanical stability.

Making the Right Choice for Your Goal

When optimizing biomass carbon for energy applications, consider how KOH aligns with your specific performance targets:

- If your primary focus is Maximum Energy Storage: KOH is ideal because it generates numerous active sites and massive surface area for charge accumulation.

- If your primary focus is High Power Delivery: The efficient transport channels created by KOH etching are essential for allowing rapid ion movement.

By leveraging KOH activation, you convert simple biomass into a sophisticated, high-performance electrode material capable of meeting modern energy demands.

Summary Table:

| Advantage | Mechanism | Impact on Performance |

|---|---|---|

| Structural Etching | Corrodes carbon skeleton | Opens internal volumes and creates hierarchical pores |

| Increased Surface Area | Hollowing of dense material | Maximizes specific surface area for chemical reactions |

| Active Site Creation | High-density reaction points | Directly improves capacity in energy storage apps |

| Enhanced Ion Transport | Multilevel pore networks | Enables rapid ion movement and high power delivery |

Elevate Your Material Research with KINTEK Precision

Are you looking to optimize your KOH activation process? KINTEK provides industry-leading high-temperature furnace solutions designed for the rigorous demands of chemical etching and carbonization. Backed by expert R&D and manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems—all fully customizable to your specific biomass treatment needs.

Whether you are scaling up supercapacitor production or refining lab-scale material synthesis, our equipment ensures the precise temperature control and durability required for aggressive chemical activators. Contact us today to discover how our tailored thermal solutions can enhance your lab's efficiency and material performance!

Visual Guide

References

- Xing Huang, Dessie Ashagrie Tafere. Waste-derived green N-doped materials: mechanistic insights, synthesis, and comprehensive evaluation. DOI: 10.1039/d5su00555h

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Spark Plasma Sintering SPS Furnace

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- Why is a high-temperature annealing process in a vacuum oven required for CMSMs? Unlock Membrane Precision

- What is the effect of sintering BZCYYb electrolyte pellets at 1000°C? Boost Your PCFC Performance Today

- What is the purpose of applying a hexagonal Boron Nitride (h-BN) coating to graphite? Enhance Purity & Tool Longevity

- Why is an optical pyrometer necessary for monitoring nickel-aluminum alloy synthesis? Capture Rapid Thermal Explosions

- Why is it necessary to dry glassware in a 140 °C oven overnight before GTP? Ensure Precise Anhydrous Polymerization

- Why is a vacuum sealing process necessary for the synthesis of TaAs2 single crystals? Ensuring Purity in CVT Method

- What is the role of MgO powder in Nickel-Aluminum VCS? Achieve Precise Thermal Control & Powder Quality

- How does a constant temperature environment maintain experimental validity? Ensuring Precision in Sulfate Attack Tests