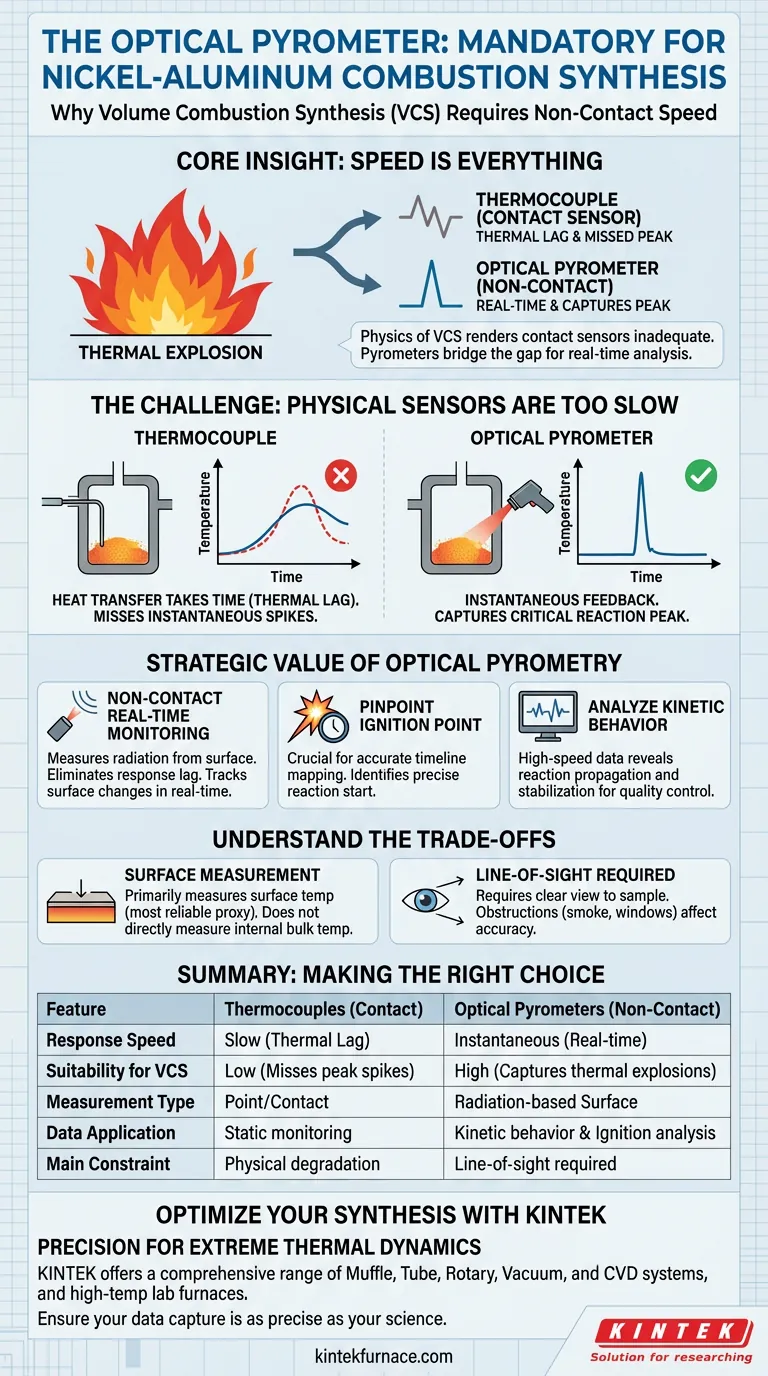

An optical pyrometer is the mandatory instrument for monitoring nickel-aluminum synthesis because the specific method used—Volume Combustion Synthesis (VCS)—generates heat too rapidly for physical sensors to track. Traditional thermocouples suffer from thermal lag and cannot capture the instantaneous temperature spikes that define this reaction, necessitating a non-contact solution.

Core Insight: The physics of Volume Combustion Synthesis involves a rapid thermal explosion that renders contact sensors inadequate. An optical pyrometer is required to bridge the gap between the reaction speed and data capture, providing the real-time temporal resolution needed to analyze ignition and kinetics.

The Physical Limitations of Standard Sensors

The Speed of Volume Combustion

The synthesis of nickel-aluminum alloys via VCS is not a slow, controlled heating process. It is characterized by extremely rapid reactions and intense heat release.

The Inadequacy of Thermocouples

Standard contact sensors, such as thermocouples, rely on heat transfer to the sensor tip. This process takes time.

Because the heat release in VCS is instantaneous, a thermocouple simply cannot respond fast enough. By the time the sensor registers a temperature change, the critical reaction peak has likely already passed.

The Strategic Value of Optical Pyrometry

Non-Contact Real-Time Monitoring

An optical pyrometer measures radiation emitted from the material, allowing for non-contact monitoring.

This eliminates the response lag associated with physical contact. It allows researchers to track surface temperature changes in real-time, matching the speed of the combustion event.

Pinpointing the Ignition Point

Determining exactly when the reaction triggers is crucial for successful synthesis.

Because the pyrometer provides instantaneous feedback, it is the critical tool for identifying the precise reaction ignition point. Without this data, it is impossible to accurately map the timeline of the synthesis.

Analyzing Kinetic Behavior

Beyond just seeing the heat, researchers need to understand the underlying mechanics of the reaction.

The high-speed data provided by the pyrometer allows for a detailed analysis of combustion kinetic behavior. This data reveals how the reaction propagates and stabilizes, which is essential for controlling the quality of the final alloy.

Understanding the Trade-offs

Surface vs. Internal Measurement

It is important to acknowledge that an optical pyrometer primarily measures surface temperature.

While this is critical for detecting ignition and surface kinetics, it does not directly measure the internal temperature of the bulk material. However, in the context of rapid VCS, the surface data is generally the most reliable proxy available for the reaction state.

Line-of-Sight Requirements

Unlike embedded sensors, an optical pyrometer requires a clear line of sight to the reacting sample. Any obstruction (smoke, reaction byproducts, or chamber windows) must be accounted for to ensure the temperature reading remains accurate.

Making the Right Choice for Your Goal

To maximize the value of your data during nickel-aluminum synthesis, align your instrumentation with your specific analytical goals:

- If your primary focus is Kinetics: Rely on the optical pyrometer to capture the millisecond-level data needed to model the reaction speed and propagation.

- If your primary focus is Process Control: Use the pyrometer's real-time data to identify the exact ignition point, ensuring the reaction has initiated correctly before moving to cooling or processing stages.

Success in Volume Combustion Synthesis depends entirely on capturing data at the speed of the reaction, making the optical pyrometer an irreplaceable asset.

Summary Table:

| Feature | Thermocouples (Contact) | Optical Pyrometers (Non-Contact) |

|---|---|---|

| Response Speed | Slow (Thermal Lag) | Instantaneous (Real-time) |

| Suitability for VCS | Low (Misses peak spikes) | High (Captures thermal explosions) |

| Measurement Type | Point/Contact | Radiation-based Surface |

| Data Application | Static monitoring | Kinetic behavior & Ignition analysis |

| Main Constraint | Physical degradation | Line-of-sight required |

Optimize Your Advanced Material Synthesis with KINTEK

Precision in Volume Combustion Synthesis requires equipment that can handle extreme thermal dynamics. Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, alongside specialized high-temp lab furnaces tailored for your unique research needs.

Whether you are synthesizing nickel-aluminum alloys or developing new ceramic composites, our customizable solutions provide the stability and control necessary for high-stakes thermal processing. Contact us today to find the perfect furnace for your laboratory and ensure your data capture is as precise as your science.

Visual Guide

References

- Gülizar Sarıyer, H. Erdem Çamurlu. Production and Characterization of Ni0.50 Al0.50 and Ni0.55 Al0.45 Powders by Volume Combustion Synthesis. DOI: 10.17776/csj.1280582

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Small Rotary Kiln Calciner

- CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

- Ultra-High Vacuum Flange Aviation Plug Glass Sintered Airtight Circular Connector for KF ISO CF

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Kiln for Pyrolysis Plant Heating

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- Why is temperature gradient management necessary for high-temperature impedance measurements? Master Thermal Precision

- Why is a heating system with closed-loop feedback essential for TL analysis? Precision Tips for High-Accuracy Kinetics

- How is SEM utilized to evaluate manganese phosphate catalysts after calcination? Verify Nanosheet Integrity.

- How does high-purity argon gas affect the production of ultrafine magnesium powder in evaporation-condensation methods? Master Particle Size Control

- What is the function of a laboratory vacuum drying oven for Fe-N-C catalysts? Preserve Nanoporous Structure

- How is a mass spectrometer utilized in TPO tests for catalysts? Enhance Your Material Characterization

- What is the role of a precision heating system in HEA synthesis? Achieve Atomic Uniformity at 220 °C

- How does a Flash Sintering (FS) system improve efficiency? Unlock Rapid Production for Titanium Diboride Composites