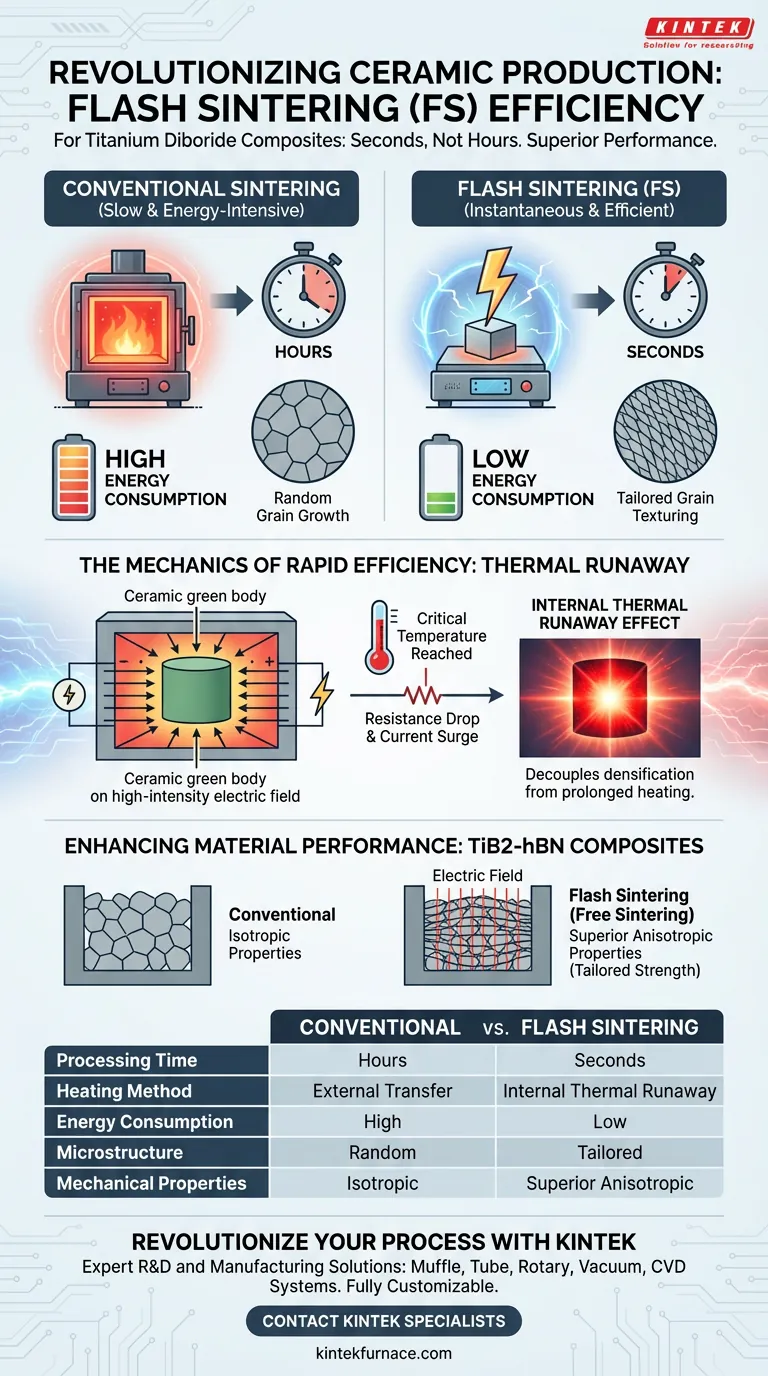

Flash Sintering (FS) systems fundamentally transform production efficiency by applying a high-intensity electric field to the ceramic green body, triggering a thermal runaway effect that densifies the material in seconds rather than hours. This process drastically reduces energy consumption while simultaneously unlocking superior mechanical properties in Titanium Diboride composites through unique microstructural control.

By leveraging electrically induced thermal runaway, Flash Sintering decouples densification from prolonged heating cycles. This allows for near-instantaneous processing that saves energy and enables specific grain texturing unavailable in conventional methods.

The Mechanics of Rapid Efficiency

Triggering Thermal Runaway

The core efficiency of an FS system lies in its ability to bypass traditional thermal lag. The system applies a high-intensity electric field to the material. Once the furnace reaches a specific critical temperature, the material's resistance drops, allowing current to surge through it.

Densification in Seconds

This surge creates a thermal runaway effect, internally heating the material rapidly. Consequently, the ceramic body densifies in a matter of seconds. This creates a massive reduction in cycle time compared to conventional sintering, which relies on slow external heat transfer.

Drastic Energy Reduction

Because the process is almost instantaneous, the total energy required to maintain high temperatures is significantly lowered. The system creates a direct link between electrical input and material consolidation, eliminating wasted energy on prolonged furnace holds.

Enhancing Material Performance

Controlled Grain Texture

Beyond speed, FS systems offer unique distinct advantages for composite materials like Titanium Diboride-hexagonal Boron Nitride (TiB2-hBN). When processed without the physical constraints of graphite molds, the electric field influences the microstructure directly.

Anisotropic Mechanical Properties

This process induces specific grain texture arrangements within the composite. As a result, the material exhibits superior anisotropic mechanical properties—meaning its strength and performance can be tailored to be higher in specific directions, optimizing it for specialized applications.

Operational Considerations and Trade-offs

The Necessity of Critical Temperature

While fast, the process is not purely electrical. The system still requires a furnace to reach a critical threshold temperature to initiate the effect. Efficiency gains are realized only after this onset point is reached.

Mold Constraints

The superior texturing effects noted in TiB2-hBN composites rely on the absence of graphite mold constraints. To achieve the specific anisotropic properties described, the tooling and setup must allow for this "free" sintering condition, which may require different handling procedures than pressure-assisted methods.

Making the Right Choice for Your Goal

To maximize the value of a Flash Sintering system for your production line, align your process parameters with your specific end-goals:

- If your primary focus is Energy Efficiency: Calibrate your system to reach the critical onset temperature quickly to trigger thermal runaway, minimizing total furnace time and maximizing throughput.

- If your primary focus is Material Performance: Remove graphite mold constraints to allow the electric field to induce specific grain alignment, resulting in superior anisotropic strength for TiB2-hBN composites.

Flash Sintering offers a rare convergence of speed and quality, turning the processing stage from a production bottleneck into a tool for microstructural engineering.

Summary Table:

| Feature | Conventional Sintering | Flash Sintering (FS) |

|---|---|---|

| Processing Time | Hours | Seconds |

| Heating Method | External heat transfer | Internal thermal runaway |

| Energy Consumption | High (prolonged holds) | Low (instantaneous) |

| Microstructure | Random grain growth | Tailored grain texturing |

| Mechanical Properties | Isotropic | Superior Anisotropic |

Revolutionize Your Material Processing with KINTEK

Transition from production bottlenecks to high-speed microstructural engineering with KINTEK. As a leader in expert R&D and manufacturing, we provide high-performance laboratory solutions including Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to your specific research or production requirements.

Whether you are aiming to slash energy costs or engineer superior anisotropic properties in Titanium Diboride composites, KINTEK delivers the precision heating technology you need to succeed. Contact our technical specialists today to discover how our customizable high-temperature furnaces can optimize your laboratory workflow.

Visual Guide

References

- Xinran Lv, Gang Yu. Review on the Development of Titanium Diboride Ceramics. DOI: 10.21926/rpm.2402009

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

People Also Ask

- What is the purpose of preheating metal molds? Enhance Fluidity and Quality in Aluminum-Lithium Squeeze Casting

- What task does a laboratory blast drying oven perform in the preparation of copper oxide precursors? Prevent Clumping

- Why is a stainless steel high-pressure autoclave essential for starch hydrogenation? Unlock Peak Reaction Efficiency

- What is the purpose of the long-term stabilization sintering step at 250°C? Secure Your CuO Nano-Network Integrity

- What processes can continuous furnaces perform in a single step? Master Debinding and Sintering for High-Volume Production

- How does an industrial vacuum drying oven affect electrode performance? Optimize Sodium-Ion Battery Stability

- What factors should be considered when selecting a furnace based on material properties? Ensure Optimal Heat Treatment

- What are the primary process advantages of using a continuous high-temperature tunnel furnace for copper tube brazing?