Precise temperature control is not optional in Thermoluminescence (TL) kinetic analysis; it is foundational. A heating system with a closed-loop feedback mechanism is essential because it ensures the temperature history of the sample is strictly regulated. Without the active correction provided by a closed-loop system, you cannot achieve the thermal stability required to accurately measure the release of charge carriers.

The validity of TL kinetic parameters depends entirely on accurate thermal detrapping. A closed-loop system maintains temperature precision within 1°C, which is strictly necessary to resolve narrow signal peaks and prevent experimental uncertainty from corrupting the analysis.

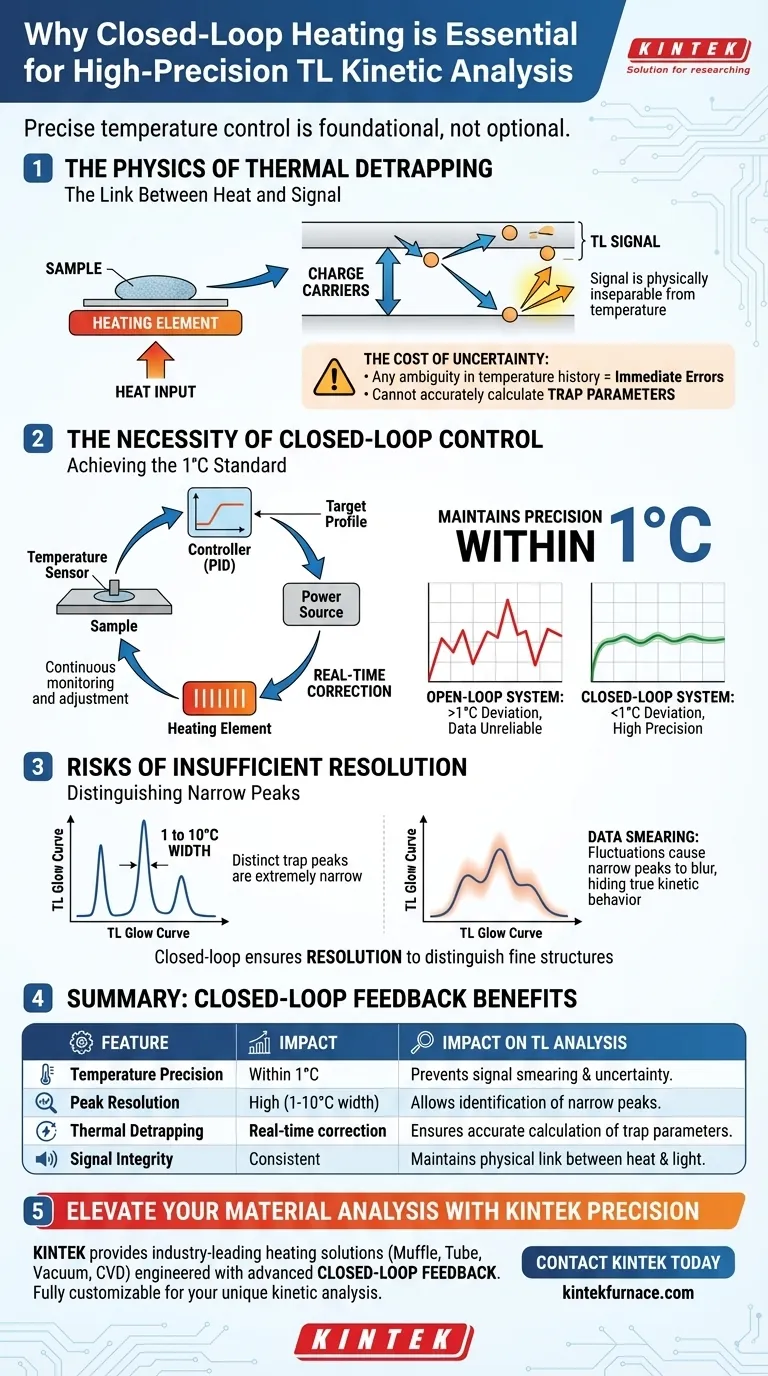

The Physics of Thermal Detrapping

The Link Between Heat and Signal

In TL analysis, the light signal you measure is generated by the thermal detrapping of charge carriers.

This means the release of energy is directly triggered by heat. Consequently, the signal is physically inseparable from the temperature applied to the sample at that specific moment.

The Cost of Uncertainty

Because the signal is thermally driven, any ambiguity in the sample's temperature history creates immediate errors.

If you do not know the exact temperature, you cannot accurately calculate the trap parameters (the specific energy characteristics of the material).

The Necessity of Closed-Loop Control

Achieving the 1°C Standard

A closed-loop feedback mechanism continuously monitors the actual temperature and adjusts the heating power in real-time to match the target profile.

This mechanism is vital because it maintains temperature control precision within 1°C.

Why High Precision Matters

Open-loop systems, or systems with poor feedback, allow temperature accumulation or lag that exceeds this 1°C threshold.

For high-precision analysis, a deviation greater than 1°C renders the data mathematically unreliable.

Risks of Insufficient Resolution

Distinguishing Narrow Peaks

The most critical reason for this precision lies in the nature of the TL glow curve.

Distinct trap peaks in the data can be extremely narrow, often spanning a width of only 1 to 10°C.

Preventing Data Smearing

If your heating system fluctuates or drifts, these narrow peaks will blur or merge.

A closed-loop system ensures you have the resolution to distinguish these fine structures, rather than recording a "smeared" signal that hides the true kinetic behavior of the material.

Making the Right Choice for Your Goal

How to Apply This to Your Project

When selecting or configuring equipment for TL analysis, the heating stage is often the limiting factor for data quality. Review your experimental requirements against the hardware specifications.

- If your primary focus is distinct peak resolution: Ensure your controller guarantees stability within 1°C to identify peaks as narrow as 10°C or less.

- If your primary focus is calculating trap parameters: You must use closed-loop feedback to eliminate temperature history uncertainty, or your kinetic calculations will be flawed.

Ultimately, high-precision TL analysis requires that the thermal input is as strictly controlled as the optical output is measured.

Summary Table:

| Feature | Closed-Loop Feedback | Impact on TL Analysis |

|---|---|---|

| Temperature Precision | Within 1°C | Prevents signal smearing and experimental uncertainty. |

| Peak Resolution | High (1-10°C width) | Allows identification of distinct, narrow trap peaks. |

| Thermal Detrapping | Real-time correction | Ensures accurate calculation of trap energy parameters. |

| Signal Integrity | Consistent | Maintains physical link between heat input and light output. |

Elevate Your Material Analysis with KINTEK Precision

High-precision Thermoluminescence analysis demands the strictest thermal control. KINTEK provides industry-leading heating solutions—including Muffle, Tube, Vacuum, and CVD systems—engineered with advanced closed-loop feedback for laboratory excellence.

Backed by expert R&D and manufacturing, our systems are fully customizable to meet your unique kinetic analysis requirements. Don't let temperature drift compromise your data.

Contact KINTEK today to discuss your custom furnace needs

Visual Guide

References

- Hayder Khudhair Obayes. Review: Theory of Thermoluminescence & Related by Reuven Chen (Author), Stephen W S Mckeever. DOI: 10.55640/eijmrms-05-07-02

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- Why is a forced-air drying oven necessary for impregnated kaolin catalysts? Achieve Uniform Component Immobilization

- Why are User-Defined Functions (UDFs) necessary for modeling complex combustion? Unlock Precision in Furnace Simulation

- Why is a pre-melting process required in phase equilibrium studies? Reset Your Sample for Precise Results

- What role does the addition of NaCl as a diluent play in the SHS of Titanium Diboride? Master Nano-Powder Synthesis

- How does the SCRS model simplify furnace combustion simulation? Efficiency Meets Accuracy in Thermal Modeling

- What are the advantages of using independent Ru and Mo targets? Master Stoichiometric Control in Magnetron Sputtering

- What are the technical advantages of vacuum drying ovens for CeO2 separators? Protect Nanostructures & Boost Stability

- Why is a homogeneous reactor used for crystallization? Achieve 100% Thermal Uniformity for Pure Crystals