A constant temperature environment acts as the critical stabilizer for chemical kinetics during External Sulfate Attack (ESA) experiments. By strictly maintaining the setup at 20 °C, researchers ensure that the periodic replacement of sulfate solutions does not introduce thermal variables that would skew the data. Because chemical reaction rates and ion migration coefficients are highly sensitive to temperature, this thermal control ensures that the corrosion process remains consistent regardless of when the solution is refreshed.

By pairing a stable thermal environment with regular solution updates, you effectively simulate a near-infinite sulfate supply. This methodology isolates material formulation as the primary variable, ensuring that observations reflect true durability rather than environmental inconsistencies.

The Mechanics of Experimental Validity

To understand why temperature control is non-negotiable during solution replacement, one must look at the underlying chemistry of sulfate attacks.

Controlling Reaction Rates

External Sulfate Attack (ESA) is driven by chemical reactions between the sulfate solution and the material. These reactions are not static; they are thermally dependent.

Even minor fluctuations in temperature can significantly accelerate or decelerate these reaction rates. By locking the temperature at 20 °C, you ensure the baseline speed of corrosion remains constant throughout the entire testing period.

Regulating Ion Migration

The durability of a material is largely determined by how deeply and quickly ions can penetrate it. This is governed by diffusion coefficients, which dictate the movement of ions through the material's pore structure.

Like reaction rates, diffusion is highly sensitive to heat. A constant temperature ensures that the rate of ion ingress is driven solely by the material's permeability, not by external thermal energy.

Simulating a "Near-Infinite" Supply

The ultimate goal of replacing the sulfate solution is to maintain a high concentration of aggressive agents. However, replenishment alone is insufficient without thermal control.

Creating Consistency

Researchers typically update solutions on a weekly, bi-weekly, or monthly basis to replenish sulfate levels. If the temperature varied between these updates, the "aggressiveness" of the new solution would fluctuate wildy.

A constant temperature ensures that every fresh batch of solution acts with the exact same kinetic potential as the previous one.

The Infinite Supply Model

When you combine regular solution updates with a fixed temperature, you create a simulation of a near-infinite sulfate supply source.

This setup prevents the solution from becoming "exhausted" while simultaneously preventing thermal spikes from artificially accelerating the attack. This balance is what allows for valid long-term data collection.

Understanding the Trade-offs

While maintaining a constant temperature is the gold standard for laboratory validity, it is important to recognize the limitations and requirements of this approach.

The Disconnect from Field Conditions

A constant 20 °C environment is an idealization. Real-world structures are exposed to diurnal and seasonal thermal cycles, which can induce physical stresses (like expansion and contraction) that a constant-temperature test will not capture.

Therefore, this method is superior for comparative analysis of materials but may not perfectly predict service life in environments with extreme thermal swings.

Resource Intensity

Maintaining a strict thermal environment requires reliable climate control chambers or water baths. This increases the energy cost and complexity of the experimental setup compared to ambient room-temperature testing.

However, relying on ambient temperature introduces uncontrolled variables that render long-term comparisons scientifically invalid.

Ensuring Reliable Data for Your Project

The decision to implement strict thermal controls depends on the specific goals of your research or quality assurance program.

- If your primary focus is comparative material evaluation: You must maintain a constant temperature to ensure that differences in durability are due to material formulation, not environmental flux.

- If your primary focus is simulating specific field conditions: You may need to supplement these standard tests with thermal cycling protocols to account for physical stresses.

Consistency in the environment is the only way to guarantee certainty in the result.

Summary Table:

| Factor | Role in Experimental Validity | Impact of Thermal Control (20 °C) |

|---|---|---|

| Chemical Kinetics | Governs reaction rates between sulfate and material. | Prevents artificial acceleration or deceleration of corrosion. |

| Ion Migration | Controls the movement of ions through material pores. | Ensures diffusion is driven by permeability, not external heat. |

| Solution Refresh | Simulates a near-infinite sulfate supply. | Guarantees consistent kinetic potential across all replenishment cycles. |

| Data Integrity | Isolates material formulation as the primary variable. | Eliminates environmental fluctuations to ensure reliable comparative data. |

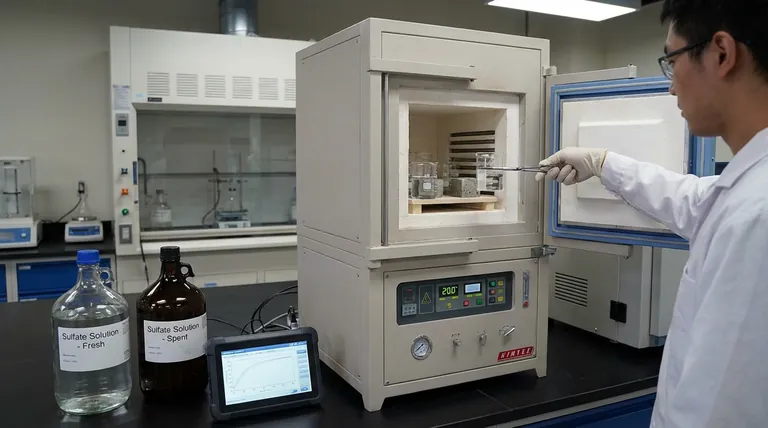

Elevate Your Material Testing with KINTEK Precision

Consistency in the laboratory environment is the only way to guarantee certainty in your results. KINTEK provides the high-performance thermal solutions necessary to eliminate variables and maintain strict experimental validity.

Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of lab high-temperature furnaces and thermal systems, including Muffle, Tube, Rotary, Vacuum, and CVD systems. Whether you are simulating sulfate attacks or conducting advanced material synthesis, our systems are fully customizable to meet your unique research needs.

Don't let thermal fluctuations skew your data. Contact us today to find the perfect solution for your lab and experience the KINTEK advantage in precision and durability.

References

- François El Inaty, Othman Omikrine Metalssi. Long-Term Effects of External Sulfate Attack on Low-Carbon Cementitious Materials at Early Age. DOI: 10.3390/app14072831

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- What is a horizontal furnace? A space-saving heating solution for attics and crawl spaces

- Why are a blast drying oven and a freeze dryer both necessary for GO nanofibers? Essential Drying Synergy

- What role does a nitrogen curtain protection system play in copper tube welding? Ensure Peak Joint Integrity

- What is tempering, and when is it used? Optimize Metal Toughness and Durability

- What is a continuous furnace? The High-Volume Solution for Efficient Thermal Processing

- Why is precision temperature control critical for MnBi2Te4 growth? Ensure Success in Flux Method Crystallization

- How does a gas evolution analysis system monitor gas release? Optimize Your Casting Integrity

- What effect does water-quench cooling equipment have on the microstructure of Invar 36? Expert Analysis