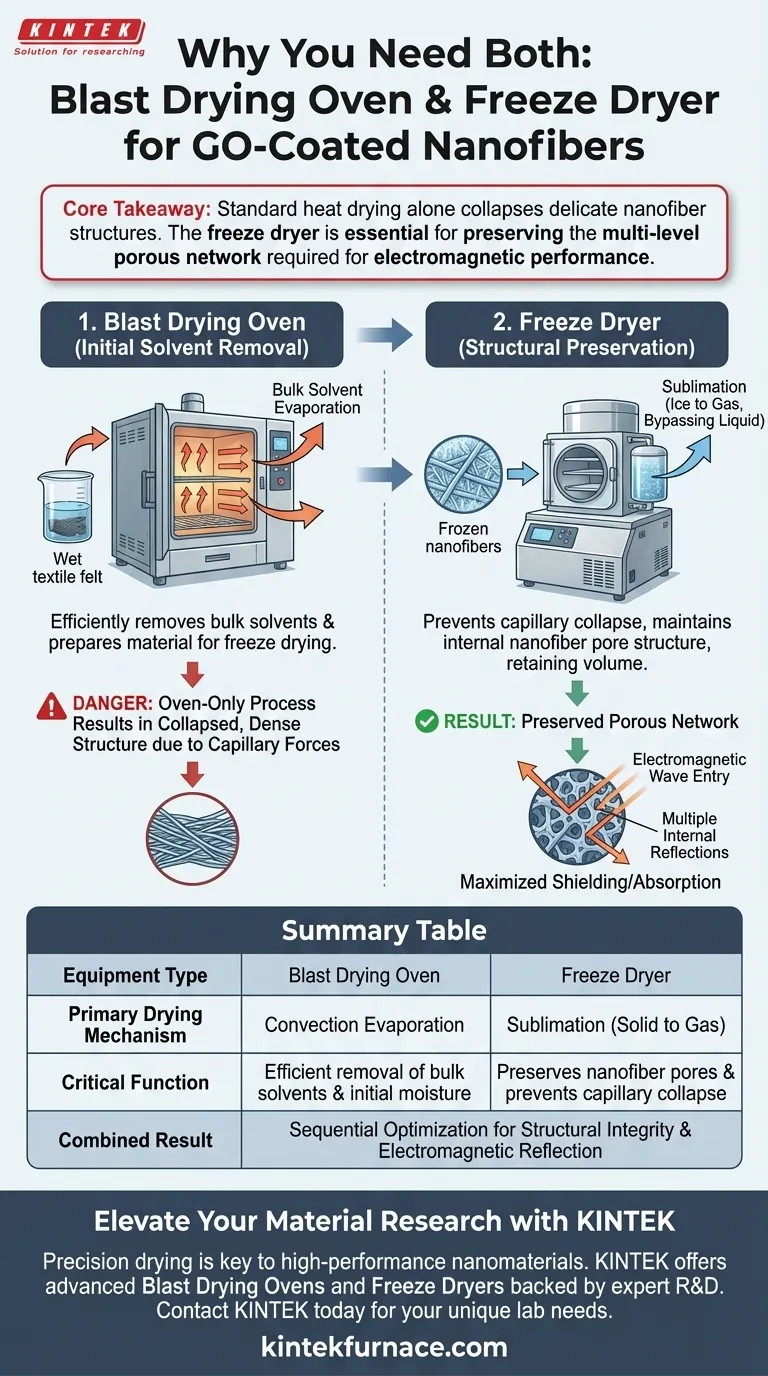

The blast drying oven and freeze dryer serve distinct, sequential roles in the preparation of graphene oxide (GO) coated nanofibers to balance basic drying with structural preservation. The blast drying oven is utilized to initially remove bulk solvents from the textile felt, whereas the freeze dryer is required to remove remaining moisture via sublimation to protect the material's microscopic architecture.

Core Takeaway Standard heat drying alone generates capillary forces that collapse the delicate internal structure of nanofibers. The freeze dryer is essential because it bypasses liquid evaporation, preserving the multi-level porous network required for the material to effectively absorb and reflect electromagnetic waves.

The Role of the Blast Drying Oven

Initial Solvent Removal

The process begins with the blast drying oven. Its primary function is to remove solvents from the textile felt efficiently.

Preparing for Sublimation

This step handles the bulk of the drying workload. It prepares the material for the more precise and delicate phase of freeze-drying that follows.

The Critical Function of Freeze Drying

Sublimation vs. Evaporation

Unlike the oven, the freeze dryer removes moisture through sublimation at extremely low temperatures. This means the moisture transitions directly from a solid state (ice) to a gas, bypassing the liquid phase entirely.

Preventing Structural Collapse

The central reason for using a freeze dryer is to avoid the capillary forces associated with liquid evaporation. When liquid evaporates in a standard oven, the surface tension can pull the nanofiber walls together, causing the structure to shrink or collapse.

Preserving Internal Pores

By using sublimation, the freeze dryer maintains the integrity of the nanofiber pore structure. This results in a material that retains its original volume and open network rather than collapsing into a dense film.

Why Structure Determines Performance

Enabling Electromagnetic Entry

The preserved, multi-level internal pores are critical for the material's function. They allow electromagnetic waves to enter the material rather than bouncing off the surface.

Facilitating Multiple Reflections

Once the waves enter the porous structure, they undergo multiple reflections within the internal cavity. This mechanism is vital for dissipating energy and maximizing the shielding or absorbing performance of the GO coating.

Common Pitfalls to Avoid

The Danger of Shortcuts

Attempting to complete the entire drying process in a blast drying oven is a common error. While it will dry the material, it will likely result in a collapsed, dense structure.

Loss of Functionality

Without the open pore network preserved by freeze-drying, the material loses its ability to trap electromagnetic waves. A collapsed structure prevents the necessary multiple internal reflections, rendering the GO coating significantly less effective for its intended application.

Making the Right Choice for Your Goal

To ensure your GO-coated nanofibers perform as intended, apply the drying stages based on the specific physical requirements of the material:

- If your primary focus is bulk solvent removal: Use the blast drying oven as a preliminary step to handle the initial drying load efficiently.

- If your primary focus is electromagnetic performance: You must use a freeze dryer for the final stage to prevent pore collapse and ensure the material can trap and reflect waves.

By combining these methods, you achieve a dry material that retains the complex internal architecture necessary for high-performance applications.

Summary Table:

| Equipment Type | Primary Drying Mechanism | Critical Function in GO Preparation |

|---|---|---|

| Blast Drying Oven | Convection Evaporation | Efficient removal of bulk solvents & initial moisture |

| Freeze Dryer | Sublimation (Solid to Gas) | Preserves nanofiber pores & prevents capillary collapse |

| Combined Result | Sequential Optimization | Maintains structural integrity for electromagnetic reflection |

Elevate Your Material Research with KINTEK

Precision in drying is the difference between a collapsed film and a high-performance porous network. KINTEK provides the advanced thermal and vacuum solutions required for sophisticated nanomaterial synthesis. Backed by expert R&D and manufacturing, we offer high-performance Blast Drying Ovens, Freeze Dryers, and customizable Vacuum and CVD systems designed to meet your specific lab requirements.

Don't let improper drying compromise your graphene oxide research. Contact KINTEK today to consult with our experts on the perfect equipment for your unique needs.

Visual Guide

References

- Mengyao Guo, Guohua Chen. Reduced Graphene Oxide Modified Nitrogen-Doped Chitosan Carbon Fiber with Excellent Electromagnetic Wave Absorbing Performance. DOI: 10.3390/nano14070587

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- HFCVD Machine System Equipment for Drawing Die Nano Diamond Coating

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Sintering and Brazing Furnace

- Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

People Also Ask

- Why is vacuum impregnation necessary for PAN-GF electrodes? Ensure Peak Fiber Conductivity and Slurry Integration

- What is the purpose of using nitrogen cylinders and flowmeters? Ensure Superior Carbon Fiber Recovery

- What effect does water-quench cooling equipment have on the microstructure of Invar 36? Expert Analysis

- What role does Sodium Chloride (NaCl) play as a thermal buffer? Optimizing Si/Mg2SiO4 Composite Synthesis

- Why is a high-precision mass flow controller essential for long-term restart performance testing of catalysts?

- What is the function of an electric arc furnace in the preparation of aluminum-silicon model alloys? Expert Insights

- Why is a high-pressure reactor with a PTFE lining required for V-NbOPO4@rGO? Ensure Purity in Acidic Synthesis

- How does optimizing fuel gas mass flow affect the thermal efficiency of an industrial furnace? Maximize Heat Retention